When you hear “labelling system,” it is easy to picture a simple machine that sticks labels onto products. But an advanced labelling system is a different kind of tool. It is less like a basic sticker applicator and more like the central nervous system of your production line.

Think of it this way: a basic applicator is a pocket calculator, doing one job reliably. An advanced system is a powerful, networked computer, orchestrating a dozen complex tasks at once.

These systems are the backbone of modern manufacturing and logistics, particularly in the UK where compliance and traceability are non-negotiable. They do not just print and apply; they integrate real-time data, manage complex information, and confirm every single product that leaves your facility is perfectly identified, tracked, and compliant.

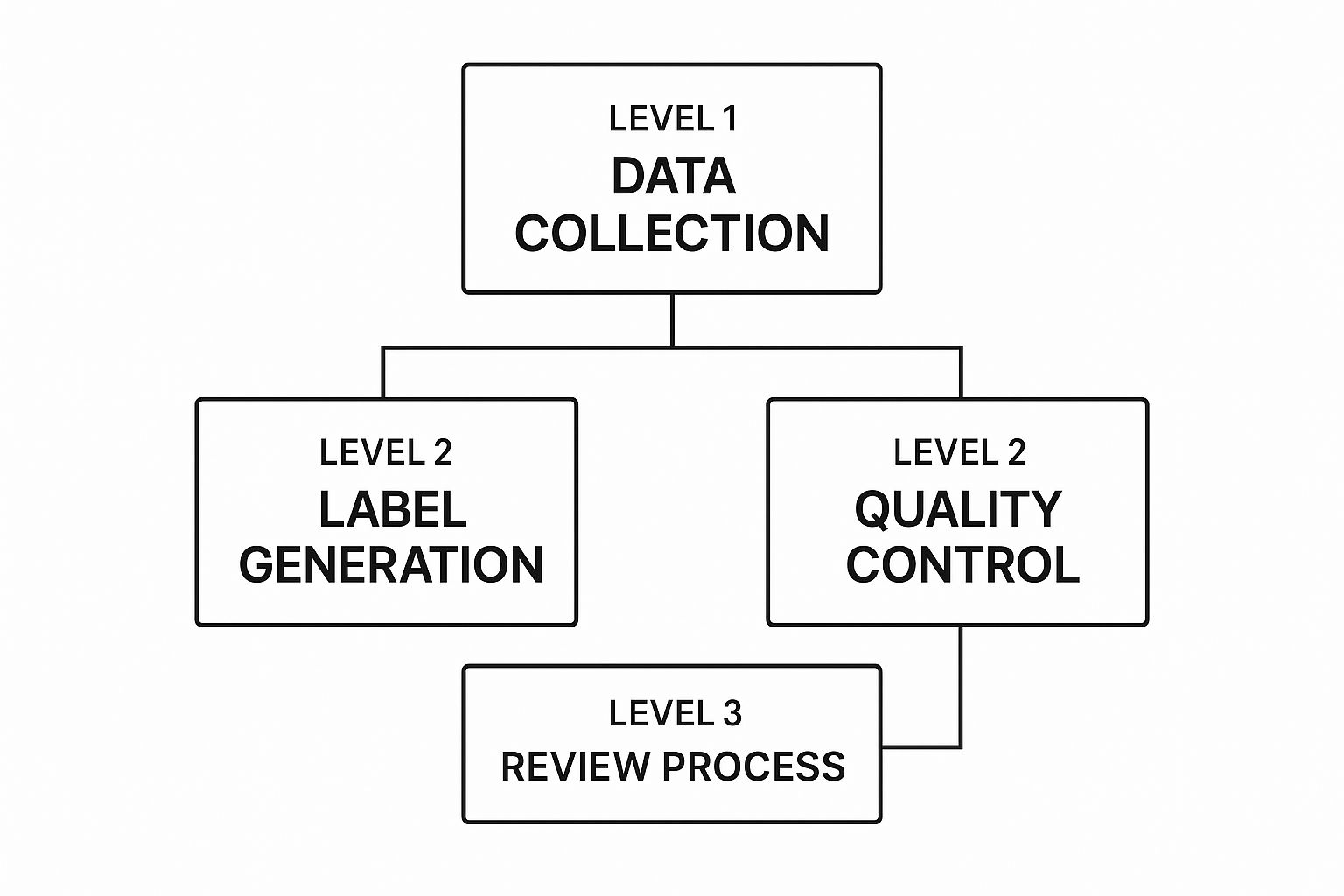

As you can see, it is a structured workflow. It all starts with reliable data, which then flows through generation, application, and quality control, with checks built in at every stage.

So, what makes these systems “advanced”? It boils down to a tight-knit combination of intelligent software, automated hardware, and sophisticated data management. These three pillars work in concert to tackle the real-world challenges of a busy production floor. This powerful combination is why the market is growing so quickly.

The global market for these integrated systems was valued at £1.65 billion in 2023 and is expected to climb to £2.4 billion by 2031. This growth is not surprising when you consider the push towards automation and smart technologies like RFID in critical industries like food, beverage, and pharmaceuticals.

To get a sense of how these pieces fit together, let’s break down the core components.

The table below outlines the technological pillars that define an advanced labelling system, showing how they work together.

| Component | Function | Example Application |

|---|---|---|

| Intelligent Software | Acts as the “brain,” designing labels, managing data, and connecting with other business systems (ERP, MES). | A food producer’s software automatically pulls allergen data and “use by” dates directly from the central database. |

| Automated Hardware | The “body” that physically prints and applies the labels with high speed and precision, including scanners. | A high-speed print-and-apply machine applies a unique serialised code to each pharmaceutical bottle on a fast-moving line. |

| Data Management & Connectivity | The “network” that confirms accurate, real-time information flows between the system and the wider business. | A logistics hub’s system receives shipping data, prints the correct courier label, and sends tracking info back to the ERP. |

Each part is crucial, but their integration unlocks the system’s true power.

The real difference is how these systems talk to the rest of your business. They do not operate in a silo. By plugging directly into your Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES), they pull live, accurate data for every single label.

This completely removes the guesswork and the costly risk of human error from manual data entry.

Imagine a pharmaceutical bottling line. An advanced system can pull the correct batch number, expiry date, and serialisation code directly from the company’s central database, print it, and verify it with a scanner-all in a fraction of a second. This level of integration is not just a “nice-to-have”; it is fundamental for safety, compliance, and protecting your brand’s reputation.

For a primer on the foundational equipment involved, our guide on what is a labelling system is a great place to start. From there, we can look deeper into the specific technologies that make all this possible.

To really get what makes advanced labelling systems tick, we need to peek under the bonnet. It is not about one single piece of kit; it is a finely tuned collection of sophisticated hardware, clever software, powerful sensors, and connectivity. This combination is what truly separates a modern system from a basic label applicator, delivering the kind of speed, accuracy, and control that modern production lines demand.

The physical machinery is what you see first, the muscle of the operation. In an advanced setup, this hardware is engineered for high-speed, repetitive work with pinpoint precision. It is all about taking out the manual labour that so often leads to mistakes and hold-ups.

This kind of automation directly tackles the challenge of throughput. While a person might label a few products per minute, a good print-and-apply system can process hundreds. That is a massive jump in output without needing to hire more staff.

If the hardware is the engine, the software is the brain-the command centre directing every move. Modern labelling software has evolved far beyond simple design tools. It now acts as a central hub for all your label data and workflows, linking the factory floor to the rest of the business.

This software creates a single source of truth for all your label designs, so you never have to worry about an operator using an old or incorrect template. More importantly, it integrates directly with your core business systems, like Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). This link allows it to automatically pull real-time data-batch numbers, ingredient lists, shipping addresses-confirming every single label is 100% accurate the moment it is printed.

By centralising control and automating the flow of data, intelligent software practically eliminates the risk of human error during data entry. This is non-negotiable in tightly regulated industries like food and pharmaceuticals, where one wrong digit could trigger a very expensive recall.

So, how does an advanced system know it has done the job right? That is where machine vision and sensors come into play. These are the system’s eyes and ears, providing constant, real-time quality control without getting in the way of production.

In the blink of an eye, high-resolution cameras and smart sensors run a series of critical checks:

It is not just about checking the final label, either. Advanced systems often need precise feedback on where a product is before the label is even applied. They use various types of position sensors to guarantee absolute accuracy. If a product fails any of these automated checks, it can be instantly flagged or diverted off the line, making certain a faulty item never makes it out the door.

The final piece of the puzzle is connectivity. The Internet of Things (IoT) and cloud platforms weave the entire labelling operation into a single, connected network. This gives managers a bird’s-eye view, allowing them to monitor performance from anywhere, track products in real-time, and collect a goldmine of operational data.

For instance, a production manager can pull up a live dashboard on their tablet showing line speeds, error rates, and when they will need more label stock, all without setting foot on the factory floor. This data is invaluable for spotting inefficiencies and making smart, informed decisions. The cloud also makes it a breeze to roll out system updates and manage label templates across multiple sites, confirming your brand and regulatory information are consistent, no matter where your products are made.

If the automated hardware is the muscle of a modern labelling system, providing speed and precision, then the software is the brain. Think of it as the central command centre. This is not just about designing a nice-looking label; it is the intelligence hub that manages complex compliance, plugs directly into your company-wide data, and guarantees every single label is perfect before it even thinks about hitting the printer. This centralisation is what elevates a labelling process from merely functional to truly excellent.

It is this kind of operational intelligence that is driving huge growth in the market. In fact, the global labelling software market is projected to expand from £441.2 million in 2024 to £775.9 million by 2034. This surge is fuelled by ever-tightening regulations and new technological possibilities. For any UK business in sectors like food or pharmaceuticals, this software is not just a nice-to-have; it is a key component for complying with stringent rules like the UK Food Information Regulations 2014.

Basic, entry-level tools are fine for dragging and dropping a few text boxes, but the software powering an advanced system is playing a completely different game. It is built to handle complex, dynamic information without someone having to manually type things in for every print job. This power comes from a few core functions that work together to stamp out errors and enforce consistency across the board.

Here is what sets it apart:

The ultimate goal is to create a single source of truth for all label data. When the software pulls information directly from a verified database, you eliminate the risk of typos or incorrect data entry on the factory floor-a common and costly cause of product recalls.

For most UK businesses, the information on a label is rarely static. Ingredients lists are updated, batch numbers are unique to every production run, and allergen information has to be both accurate and prominent. Advanced software is designed to automate all of this variable data, making compliance much easier to manage.

Take a food manufacturer, for instance. They can use a single master template for a product, and the software will automatically populate the right information for each run:

This automation is just as powerful for regional and international requirements. If you are a UK business exporting to the EU, the software can handle multi-language support without breaking a sweat. It can instantly switch text fields to French, German, or Spanish depending on the destination, all from the same master template. Our guide to software for labels printing looks deeper into how these solutions are put together.

When you boil it all down, the strategic role of this software is risk mitigation. A mislabelled product can trigger huge financial losses from recalls, tarnish your brand’s reputation, and, in some industries, create serious safety risks for consumers.

By building a controlled, automated, and centralised process, advanced software acts as your best line of defence. It gives you the power to adapt to new product information or regulatory updates almost instantly, knowing with confidence that every label that comes off the line is consistent, compliant, and correct.

The theory behind advanced labelling systems is one thing, but seeing them in action is where their value truly hits home. Across the United Kingdom, these systems are not just a “nice-to-have” for efficiency; they are a central part of meeting strict regulations, protecting consumers, and staying competitive.

You can see their impact everywhere, from high-speed food production lines in the Midlands to sterile pharmaceutical facilities in the South East. The UK’s strong industrial base in pharmaceuticals, food, and manufacturing creates the perfect environment for these automated solutions. Businesses are rapidly adopting them not only to speed up production but to make certain they are compliant with tough industry rules. For instance, the pharmaceutical sector absolutely depends on automated labelling for the patient safety and traceability mandated by the MHRA. You can find more data on the UK’s uptake of automated labelling on gminsights.com.

In the relentless pace of the food and beverage industry, there is no room for error. A single mistake on an allergen warning can lead to devastating consequences, triggering expensive recalls and shattering consumer trust for good. Advanced labelling systems tackle this problem head-on by linking directly with central databases.

Picture a UK bakery launching a new line of gluten-free biscuits. The labelling system automatically pulls the approved ingredient list, making certain allergens like nuts or soya are highlighted in bold to comply with UK Food Information Regulations. As the biscuits travel down the production line, a print-and-apply machine adds a unique batch code and “best before” date to every single pack, giving it full traceability from the factory floor to the supermarket shelf.

This kind of automation eliminates the risk of an operator grabbing the wrong roll of labels or manually keying in the wrong information-a critical safeguard when you are producing thousands of items an hour.

When it comes to the UK’s pharmaceutical sector, labelling is a life-or-death matter. The Medicines and Healthcare products Regulatory Agency (MHRA) enforces incredibly strict requirements for serialisation and traceability to fight counterfeit drugs and guarantee product integrity. Advanced systems are the foundation of this compliance.

Think about a company packaging a prescription medicine. An advanced system handles several crucial jobs in one pass:

If any label fails this check, the system instantly rejects the carton from the line. This closed-loop process creates a complete, auditable trail, proving every product is correctly labelled and secure before it even thinks about entering the supply chain. You can see how an automatic labeler machine performs these precise tasks.

This level of automated verification is not just about ticking boxes for regulators. It is a fundamental part of protecting public health and the hard-earned reputation of pharmaceutical brands.

To fully grasp the operational leap, let’s compare the old way of doing things with the new.

The table below breaks down the key differences, showing just how significant the upgrade to an advanced system can be.

| Operational Area | Manual/Basic System | Advanced System |

|---|---|---|

| Speed & Throughput | Slow, operator-dependent, often creates bottlenecks. | High-speed, continuous operation, matches production line speeds. |

| Accuracy & Error Rate | Prone to human error (wrong label, typos, misapplication). | Near-perfect accuracy (over 99.9%), with automated verification. |

| Data Integration | Disconnected; requires manual data entry from a spreadsheet or list. | Fully integrated with ERP/WMS; pulls live data automatically. |

| Regulatory Compliance | Difficult to track and audit; relies on manual record-keeping. | Built-in audit trails, supports compliance with serialisation rules (MHRA). |

| Flexibility | Time-consuming to change label formats or product lines. | Quick and easy changeovers managed through a central interface. |

| Traceability | Limited to basic batch codes, difficult to track individual items. | Complete end-to-end traceability with unique serial numbers per item. |

As you can see, the shift is not just an incremental improvement-it is a complete operational overhaul that delivers benefits across the board.

Inside a busy UK warehouse or distribution centre, everything hinges on speed and precision. A single mislabelled pallet can cause shipping chaos, throw stock levels into disarray, and leave you with very unhappy customers. This is where advanced labelling systems, linked directly to a Warehouse Management System (WMS), keep the entire operation running like clockwork.

When an order is picked and ready to go, the system instantly generates a GS1-compliant shipping label with the right address, barcode, and routing details. For larger goods on pallets, a robotic arm can even apply labels to multiple sides without ever stopping the conveyor. This level of automation practically eliminates picking errors and dramatically cuts down dispatch times, making certain orders get where they need to go, right on schedule.

It is not just the highly regulated sectors that benefit. General manufacturing sees huge advantages, too. Whether you are making automotive parts or consumer electronics, accurate product identification is key for tracking items internally and giving visibility across the supply chain.

For example, a UK-based electronics manufacturer might use an advanced system to apply tiny, durable labels printed with serial numbers and QR codes onto individual components. This allows them to track that specific component’s entire journey through assembly, testing, and final installation. Having this detailed work-in-progress data helps them spot production bottlenecks early and ramp up quality control, guaranteeing only perfect products leave the factory.

Picking an advanced labelling system is a big deal. It is not just about buying a new piece of kit; it is about finding a solution that slots right into your production line, talks to your other systems, and can grow with you for years to come. Think of it less like a purchase and more like a long-term partnership.

The best place to start is not with glossy brochures, but with a hard look at your own operations. Getting a crystal-clear picture of what you actually need creates a roadmap, guiding you to the right hardware, software, and supplier. If you skip this step, you risk either overspending on features you will never use or, even worse, underspending and ending up with a system that causes more headaches than it solves.

Before you even glance at a potential system, you have to define what “the right system” means for your business. This internal audit is easily the most important part of the journey. A setup that is perfect for a pharmaceutical giant would be completely wrong for a local craft brewery.

Start by asking a few practical questions about your production floor:

Doing this groundwork gives you a solid operational baseline and helps you build a non-negotiable checklist for any system you consider.

With your requirements list in hand, you can start weighing up your options. It is often helpful to look at the software (the brains) and the hardware (the brawn) separately to make certain both sides of the equation are a perfect fit.

When it comes to software, how well does it integrate? Can it connect directly to your product database to pull information automatically, cutting down on human error? How easy is the interface for your team to use when designing or managing label templates? For anyone in a regulated industry, you will also need to check for compliance features like audit trails and secure user access.

On the hardware side, the physical machinery has to stand up to your production environment. The printer technology is a huge decision point-thermal transfer is fantastic for durable, long-lasting labels, while direct thermal is better suited for things with a short lifespan, like shipping labels. You also need the right applicator. A gentle air-blow applicator might be ideal for delicate products, whereas a more firm wipe-on applicator is built for high-speed lines handling sturdy, flat-surfaced boxes. For a deeper look into the machinery itself, this guide to choosing label printing machines is a great resource.

The operating environment itself is a major factor. A system destined for a cold, damp food processing facility will have very different durability requirements from one used in a clean, climate-controlled electronics assembly plant.

One of the easiest traps to fall into is fixating on the upfront cost. The real figure you should be looking at is the Total Cost of Ownership (TCO). This includes everything: installation, training, ongoing maintenance, consumables, and support over the machine’s entire life. A cheaper machine that constantly breaks down or locks you into expensive proprietary labels can quickly end up costing far more than a reliable, higher-priced alternative.

The supplier’s reputation and the quality of their long-term support are just as crucial as the tech. A great partner does not just sell you a machine and disappear. They provide thorough training, responsive technical support when things go wrong, and a dependable supply of spare parts to keep your downtime to an absolute minimum.

Before you sign on the dotted line, make certain you have solid answers to these final questions:

Choosing the right system is a strategic business decision. By taking a structured approach that starts with your needs and considers the full lifetime value of the investment, you can find an advanced labelling system that does not just work, but actively helps you hit your business goals.

Right, even after looking into the technology and seeing what these systems can do, there are always a few practical questions that pop up. It is completely understandable. When you are considering a big investment in your operations, you need to know exactly what to expect.

This final section is all about tackling those common queries head-on. We will get straight to the point on things like implementation time, financial returns, and how these systems handle the tricky, ever-changing data that defines modern production. The aim is to clear up any last bits of uncertainty before you move forward.

That is the million-dollar question, isn’t it? The honest answer is: it depends entirely on the scale of your project. There is no one-size-fits-all timeline.

For a small business needing a straightforward, software-only setup, you could be up and running in a few weeks. But for a large manufacturing plant looking to integrate a system across multiple production lines, you are realistically looking at a project spanning several months.

Think of it as a carefully planned project, broken down into clear stages to avoid disrupting your day-to-day work.

A typical project plan usually involves:

For bigger projects, we almost always recommend a phased rollout. It just makes sense. You get one line comfortable with the new system, iron out any kinks, and then expand it across the rest of the facility. It makes for a much smoother transition for everyone involved.

This is where things get really interesting. When you calculate the return on investment (ROI) for an advanced labelling system, you have to look past the initial cost of the equipment. The real financial gains come from huge boosts in efficiency, accuracy, and compliance. Most businesses find they see a positive ROI within 12 to 24 months as all these benefits start to add up.

The factors driving that strong ROI are very clear and measurable.

The biggest financial wins almost always come from wiping out costly errors. By automating data entry and verifying every single label, these systems practically eliminate the risk of product recalls, compliance fines, and wasted stock from mislabelling.

Here is where you will see the value:

When you put faster line speeds together with a near-zero error rate, the financial argument for upgrading becomes incredibly strong.

Absolutely. In fact, handling variable data is not just a feature – it is one of their core purposes. This is what truly separates them from a standard label printer. They are built from the ground up to manage labels where some information stays the same, but other bits change with every single product that goes down the line.

The magic happens by connecting the system directly to your central databases in real time. This allows it to pull whatever information is needed for that specific item, such as:

The whole process is managed through centralised templates. A designer will create a master label layout where your logo, branding, and other fixed elements are locked in. At the same time, they will designate specific fields on that label as “variable.”

So, when a product moves down the line, the system instantly grabs the correct data for that one item from the database and fills in the variable fields just before printing. The result is a perfectly accurate, professional-looking label every single time, with no need for anyone to manually type anything on the factory floor.

Finding the right system is a critical step towards improving your operational efficiency. At Sessions UK, we offer expert guidance and a full range of labelling machinery to match your specific production needs. Explore our solutions at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.