At its simplest, an asset tracking label is a way to give each of your physical items a unique digital fingerprint. Think of it as the bridge connecting your real-world equipment-like laptops, tools, or machinery-to a digital record where you can monitor its every move.

A great analogy is a car’s registration plate. The plate itself isn’t the car, but it provides a one-of-a-kind identifier that links that specific vehicle to a central database. That database holds all the important details: the owner, the model, its service history, and so on.

An asset label works in exactly the same way. It doesn’t store all the data about an item; it just holds a unique code.

When someone scans that code, it instantly pulls up the item’s complete profile from your asset management software. This gives your team immediate access to information without the headache of digging through old spreadsheets or dusty filing cabinets. The whole process is fast, accurate, and dramatically cuts down on human error.

The main job of these labels is to forge a reliable link between your physical inventory and your digital records. Without them, trying to keep tabs on hundreds-or thousands-of items is a painful, manual slog that’s just asking for mistakes. Some studies show that businesses without a proper system can lose track of up to 15% of their assets every single year.

Putting a well-organised labelling system in place delivers some immediate, practical benefits:

At its heart, an asset tracking label turns a passive object into an active, traceable part of your daily operations. It gives you real-time visibility over your company’s valuable equipment, from the day you buy it to the day it’s retired.

This foundation of reliable data is what truly unlocks modern asset management, giving you tighter operational control and paving the way for much smarter financial planning.

When it comes to choosing the right tech for your asset tracking labels, it really boils down to two main players: barcodes and Radio Frequency Identification (RFID). Think of it like deciding between sending a letter and making a phone call. Both get a message across, but their speed, cost, and the situations they’re best for are worlds apart.

Barcodes, and their more modern cousins, QR codes, are the tried-and-tested workhorses of the asset tracking world. They work on a simple line-of-sight basis: an employee has to physically point a scanner at the label to read its unique code.

This direct approach makes them perfect for tracking individual items that are handled one by one. Picture checking out a company laptop or auditing a specific piece of machinery during a maintenance check. It’s a straightforward, one-to-one interaction.

Barcodes are brilliantly simple. They are incredibly cheap to produce, easy to print, and you can read them with almost any scanner, including the smartphone in your pocket. For any business needing a no-fuss, budget-friendly way to log assets individually, barcodes are a proven solution that won’t break the bank.

But it’s not all good news. The need for a clear line of sight can be a real drag in a busy warehouse, and scanning items one by one can turn a stocktake into a marathon.

RFID technology is a completely different beast. An RFID tag has a tiny microchip and an antenna that sends out data using radio waves. The big difference? It doesn’t need a direct line of sight.

This means a single RFID reader can scan dozens, or even hundreds, of tags at once, even if they’re tucked away inside a box or stacked on a pallet on the other side of the room. We go into more detail on the nuts and bolts in our guide on what RFID labels are.

Imagine a logistics company receiving a shipment of high-value electronics. Instead of a poor soul having to scan the barcode on every single box, an employee with an RFID reader can register the entire pallet in the few seconds it takes to drive it through a doorway. This incredible boost to efficiency is why RFID is the go-to for fast-moving warehouses, high-value asset tracking, and anywhere that speed is money.

The market reflects this shift. In the UK, the smart label market is expected to rocket to around USD 136.3 million by 2030, and RFID is set to account for more than half of that.

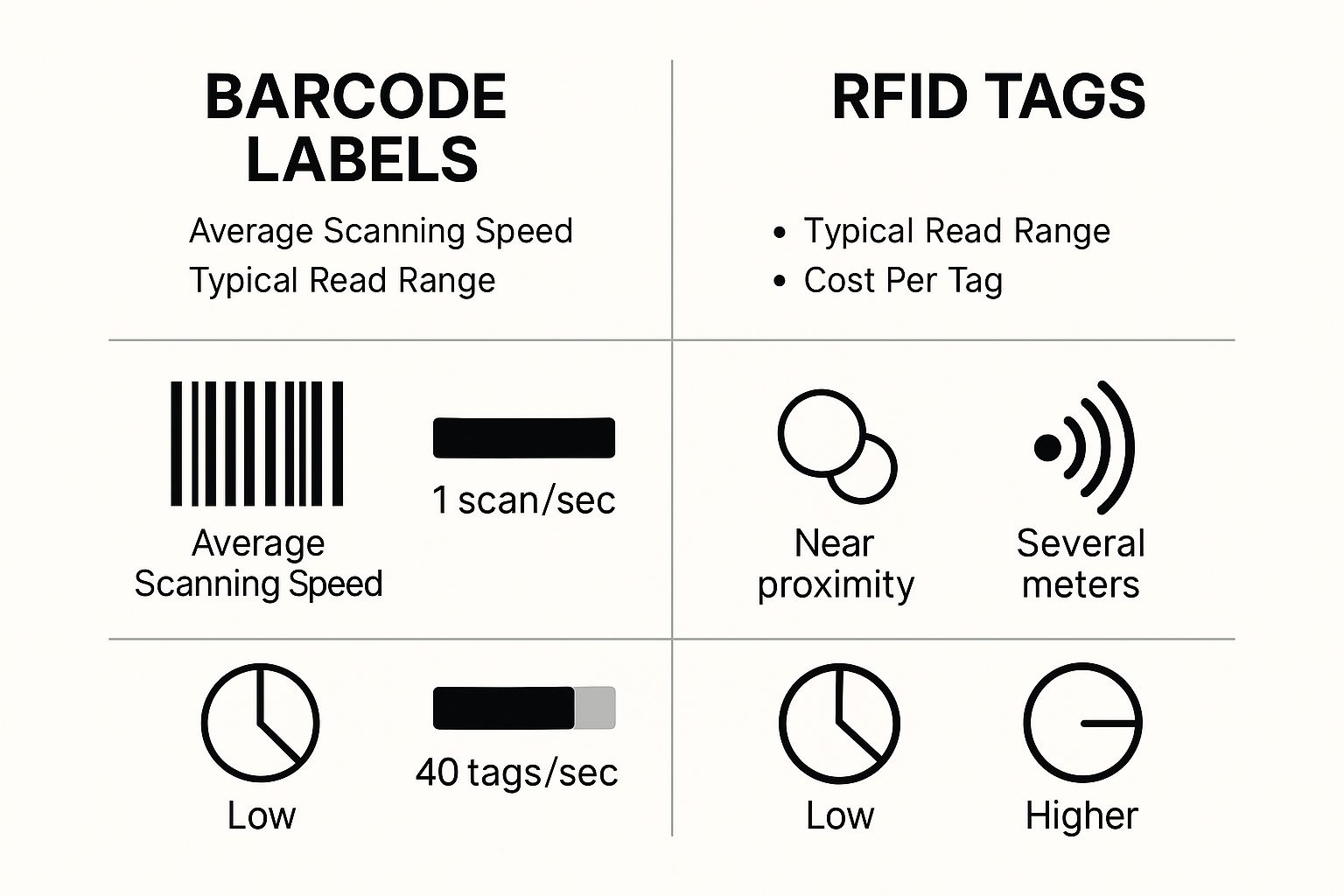

To help you decide which technology fits your operation, let’s put them head-to-head. This table breaks down the key differences in how they perform on the ground.

| Feature | Barcode Labels | RFID Labels |

|---|---|---|

| Scanning Method | Requires direct line-of-sight. | Uses radio waves; no line-of-sight needed. |

| Scanning Speed | Scans one item at a time. | Scans hundreds of items simultaneously. |

| Read Range | Short (a few inches to a few feet). | Varies, but can be up to 100 feet. |

| Data Storage | Limited; stores a simple identifier. | Can store more data, which can be updated. |

| Durability | Vulnerable to dirt, moisture, and scratches. | More resilient; tag is often protected inside. |

| Cost Per Label | Very low (pennies). | Higher (can range from 10p to several pounds). |

| Initial Investment | Low (simple scanners and printers). | Higher (readers and more complex software). |

The choice isn’t just about cost. While barcodes are cheaper per label, the massive gains in speed and labour efficiency from RFID can deliver a much greater return on investment for the right kind of business. It’s about matching the technology to the job at hand.

An asset tracking label is only ever as good as its ability to stay put and stay readable. The whole system falls apart if the label peels off, fades, or gets scraped into oblivion. Picking the wrong material is like sending a paper boat into a storm-it simply won’t last.

The environment where your asset lives and breathes is the single biggest factor in this decision. A simple paper label might be perfectly fine for a file folder in a climate-controlled office, but stick that same label on a piece of construction equipment out in the rain, and it’ll be gone in minutes.

Different materials are built to handle specific challenges, from relentless sunlight and chemical spills to constant bumps and scrapes. The best way to start is to think about the daily life of the asset you need to track. What does it go through?

Choosing the right material isn’t just about how long a label lasts; it’s about safeguarding the integrity of your entire asset management system. One failed label creates a blind spot in your inventory, leading to lost assets and wasted time trying to track things down.

For assets that face truly punishing conditions, you need to bring in the heavy hitters. These are the materials you’ll find in tough settings like manufacturing plants, logistics depots, and outdoor industrial sites.

Anodised Aluminium is one of the top contenders for heavy machinery, outdoor equipment, and anything exposed to harsh chemicals or extreme temperatures. The anodising process seals the printed information into the metal under a super-hard protective layer. This makes the label incredibly resistant to abrasion, UV damage, and corrosion. It’s why a metal plate can survive for decades on a generator, while a plastic one might give up after just one rough season.

Getting this choice right from the start saves you the massive headache and expense of having to relabel your entire inventory later. For more information, this guide to the best materials for labels is a fantastic resource.

Before you decide, run through these key questions for any asset you plan to label:

Answering these questions honestly will point you toward a label that’s fit for purpose and will see the asset through its entire working life.

You can have the most durable label material in the world, but it’s completely useless if it won’t stick. The adhesive is the real workhorse of any asset tracking label, creating the physical bond between your valuable equipment and the data you need to track it. Picking the wrong one is a surprisingly common pitfall, and it almost always ends with labels peeling away, taking your entire tracking system down with them.

The first thing to look at is the asset’s surface. A smooth, clean glass panel is worlds apart from a rough, powder-coated metal cabinet. These materials have different “surface energies,” which is just a technical way of describing how well an adhesive can grab onto them.

For clean, high-energy surfaces like bare metal or glass, a standard permanent adhesive usually does the job just fine. For more demanding applications, you’ll need something with a bit more bite.

Some surfaces are notoriously difficult to label. Low-energy plastics, like polypropylene, are a classic example-they practically repel standard adhesives. For these, you need a high-tack or aggressive adhesive. This kind of glue is engineered to form a much stronger, more immediate bond, especially on textured or tricky surfaces, so the edges don’t start lifting over time.

Of course, not every label needs to be permanent. Removable adhesives are perfect for temporary tracking, like monitoring equipment on loan or assets that get swapped between departments. They stick securely when you need them to but peel off cleanly without leaving that frustrating, sticky residue behind.

Think of the bond between a label and an asset as a chemical reaction. Everything from temperature and moisture to the texture of the surface itself plays a role in whether that bond holds strong or fails down the line.

To get it right the first time, you need to ask the right questions before you commit. For more details on the different formulas, check out our guide to understanding label adhesives.

Before you place your order, run through these simple questions for each asset type. This small bit of prep work can save you a world of headache and expense by preventing mass label failure.

Answering these will point you directly to an adhesive that’s built for the job, so your asset tracking system works flawlessly for years to come.

Let’s move away from the theory and look at where the rubber really meets the road: demanding industrial environments. For UK manufacturing and logistics firms, these labels aren’t just sticky bits of plastic; they’re the bedrock of control, efficiency, and staying competitive in a tough global market.

Picture a busy factory floor. The entire operation hinges on having the right tool for the right job, right now. Asset labels give you a direct line of sight to everything, from specialised jigs and delicate calibration tools to the heavy machinery anchoring the production line.

With a quick scan, a manager can instantly see if a critical piece of equipment is in use, down for maintenance, or ready to go. This kind of immediate insight is what slashes downtime, clears up bottlenecks, and puts a stop to the expensive habit of buying duplicate tools simply because the originals can’t be found.

In the world of logistics, the scale of the challenge is even bigger. Goods are always on the move, passing through countless hands and locations. Here, asset tracking labels are attached to everything that moves: pallets, roll cages, shipping containers, and even the lorries that carry them.

What this does is create a completely transparent and traceable supply chain. Every time an item passes a checkpoint, a quick scan updates its digital footprint. This provides the real-time visibility needed to hit tight delivery deadlines and clamp down on loss or theft. If a pallet gets misplaced, its last known location is only a few clicks away.

By attaching a simple label, companies transform passive containers and vehicles into active, monitored components of their logistics network. This digital oversight is a powerful defence against the operational chaos that can easily disrupt a supply chain.

This level of control isn’t a “nice-to-have” anymore; it’s a requirement for UK businesses. The UK’s asset tracking hardware and solutions sector is a major market, with manufacturing and logistics taking the lion’s share. Companies in these fields lean heavily on tracking hardware to keep their operations running smoothly and adhere to strict regulatory standards. You can learn more about the growth of this market and its key drivers.

Good asset management, powered by reliable asset tracking labels, is also crucial for staying compliant. Many industries in the UK are required to keep meticulous records for audits, safety inspections, and quality control.

Labels create a permanent link to an asset’s entire life story, including:

By making data collection almost effortless, these labels help UK companies prove they’re meeting regulations from bodies like the Health and Safety Executive (HSE). This organised approach does more than just tick boxes. It builds a solid foundation for operational excellence, turning a humble label into a tool that delivers huge gains in efficiency and security.

Putting a new asset tracking system in place can feel like a huge task, but it doesn’t have to be. The secret is to think of it not as one big project, but as a series of straightforward, logical steps. A successful rollout is all about the preparation you do long before a single label ever gets printed.

The very first thing you need to do is define your scope. Get specific about what you’re tracking and, critically, why. Is the goal to keep tabs on high-value laptops to stop them from walking out the door? Or are you trying to manage workshop tools to cut down on time wasted searching for them? Your core objective will shape every other decision you make.

Having this clarity is more important than ever. The demand for real-time monitoring in UK manufacturing and logistics is booming, which is why the asset tracking market is growing so quickly. You can find out more about the UK’s asset tracking market growth to see just how fast things are moving.

Once you know what you want to achieve, you can get down to the practical side of things. Nailing a few key elements from the get-go will make all the difference.

A well-planned numbering system is like a library’s cataloguing method. It brings order to what could easily become a chaotic mess of assets, making it simple for anyone in the company to find what they need, no questions asked.

With all the groundwork laid, it’s time for the final piece: applying the labels and training your team. It’s tempting to rush this stage, but that’s a common mistake that leads to labels peeling off or data being entered incorrectly. For a more detailed walkthrough, have a look at our guide on how to implement labelling solutions.

Proper application always involves:

Follow these structured steps, and you’ll build a dependable, organised system that works from day one.

When you’re getting started with asset tracking, a few practical questions always come up around cost, durability, and how to actually produce the labels. Getting these answers right from the start can save you a lot of headaches later on.

It’s easy to look at the per-label price and assume barcodes are the cheaper option. On paper, they are. That’s only a tiny part of the picture. The real cost of a barcode system includes the scanners and, more importantly, the man-hours your team spends scanning every single item individually.

RFID tags do cost more upfront, and the readers are a bigger initial investment. The return on that investment is massive. Imagine one person scanning an entire pallet of goods in a few seconds, without even needing to see the tags. That’s where RFID pays for itself – in sheer time and labour savings.

The lifespan of a label all comes down to what it’s made of and where it lives. For a standard polyester label on a piece of office IT equipment, you can easily expect it to last 5-10 years without any trouble.

What about machinery that’s constantly exposed to harsh weather, chemicals, or getting knocked about? For those jobs, you need something much tougher. Anodised aluminium labels, for instance, are built for exactly these conditions and can stay perfectly readable for 20 years or more-often outlasting the asset they’re attached to.

The golden rule is simple: your label’s lifespan should match or exceed the working life of the asset it’s tracking. Skimping on durability now only leads to the massive cost and disruption of relabelling everything down the line.

Printing your own labels can seem like a great idea, especially for small batches where you want total control. It’s not without its challenges. You’ll need to buy a specialised thermal transfer printer, keep a stock of the right label materials, and manage all the consumables yourself.

Ordering from a professional supplier opens up a whole world of possibilities. You get access to a far wider range of durable materials, industrial-grade adhesives, and protective finishes that you just can’t replicate in-house. This almost always results in a tougher, more reliable label that’s ready for any demanding environment you throw at it.

For expert advice on figuring out the best labelling solutions for your business, get in touch with Sessions UK. You can also explore our full range of industrial labelling machines to see what’s possible for your production line.

Copyright © 2026 Sessions Label Solutions Ltd.