An automatic label applicator is a machine built to apply labels to products, containers, or packages without any manual intervention. It’s best to think of it as a dedicated, highly precise worker on your production line-one that makes sure every single item gets a perfectly placed label, every time. For any business looking to scale up its operations, this kind of equipment is fundamental.

At its heart, an automatic label applicator is designed to take over a repetitive and often mistake-prone task. In any manufacturing or packaging environment, consistency is absolutely king. Labelling by hand can easily lead to crooked labels, inconsistent placement, and a much slower production pace, all of which can damage your brand’s image and hamstring efficiency. This is exactly where automated systems come in.

By mechanising the application process, these machines deliver a level of uniformity at speeds simply impossible for a human to sustain. For many UK businesses, making the switch from manual to automated labelling represents a massive leap forward in professionalising their entire production process.

An automatic label applicator is not just about going faster; it is about embedding precision and reliability into your workflow. These machines are engineered to tackle high-volume tasks while holding a standard of quality that is incredibly difficult to maintain manually. The real-world benefits are clear:

Automatic label applicators are a fantastic example of business process automation (BPA) in action, which is all about using technology to handle recurring tasks that would otherwise require manual effort.

The need for an automatic label applicator usually becomes apparent as a business starts to grow. A small start-up might get by with applying labels by hand, but as soon as order volumes climb, this manual step quickly becomes a serious production bottleneck. An automatic system is the perfect solution, allowing companies to meet rising demand without letting quality slip.

A well-implemented labelling system transforms a production line from a series of disjointed steps into a fluid, continuous operation. It is a foundational piece of equipment for any serious manufacturing venture.

Keeping these systems in top condition is surprisingly straightforward, and knowing how to keep your fully automatic labelling machines running smoothly is key to getting the most out of your investment. With the right machine, businesses in sectors from food and beverage to pharmaceuticals can make certain their products leave the factory looking professional and ready for the shelf. It is a technology that forms a crucial part of modern, efficient supply chains across the United Kingdom.

Think of an automatic label applicator as a finely tuned orchestra on your production line. It is not just one action; it’s a sequence of perfectly timed movements that result in a perfectly placed label, happening over and over again with incredible speed and precision.

It all starts the moment a product glides into the applicator’s zone on a conveyor. A small sensor, like a gatekeeper, detects the product and sends a signal: “We’ve got one, get ready!” This single electronic pulse kicks the entire machine into gear.

The first thing that happens is the drive system whirs to life, pulling just one label forward from a massive roll. This has to be exact – too much or too little pull, and you’ll get a jam.

At the very heart of the machine is the clever way it separates the sticky label from its backing paper. This is all down to a simple but brilliant component called a peel plate (or sometimes a peel bar). As the roll of labels is pulled sharply over this thin, angled edge, the flexible backing paper bends away. The label itself, being a bit stiffer, keeps going straight, lifting cleanly off the liner.

It’s the same motion you use when peeling a sticker by hand – you bend the paper back to pop the sticker’s edge up. The peel plate just automates that simple flick of the wrist, doing it flawlessly every time. The label is now held in place, adhesive side out, waiting for its product. Meanwhile, the now-useless backing paper is neatly wound onto a take-up spool, ready for disposal.

The final step is the transfer. An applicator head moves in to place the label onto the product. Depending on the machine, this can happen in a few different ways:

Many of the more advanced systems, particularly tamp-blow and air-blow applicators, rely on compressed air for their quick, precise movements. If you’re curious about the mechanics behind this, exploring some basic pneumatic system principles gives you a great insight into how they work.

When you’re looking into automatic labellers, you’ll quickly find they fall into two main camps: standard applicators and print-and-apply systems. Choosing the right one is critical and depends entirely on what information your labels need to show.

A standard automatic label applicator is designed to work with pre-printed labels. The rolls you load into it already have all the branding, text, and barcodes printed on them.

This setup is perfect when you’re applying the exact same label to thousands of products. Imagine a craft brewery canning its flagship IPA; every can gets the same beautiful, branded label. For high-volume runs where the information never changes, a standard applicator is the most straightforward and cost-effective choice.

A print-and-apply automatic label applicator has a built-in thermal printer. This is a big deal. It prints variable, unique information onto each label just seconds before applying it.

This is absolutely necessary in industries like logistics. Every package leaving a warehouse needs a label with a unique address, a distinct tracking barcode, and specific shipping details. A print-and-apply system creates that label on demand. Other common uses include:

While these systems are more complex, they offer enormous flexibility. You no longer need to keep a stock of thousands of different pre-printed label variations. The choice between a standard applicator and a print-and-apply model really comes down to one simple question: is your label data static, or does it need to change from one product to the next?

Choosing the right automatic label applicator isn’t a one-size-fits-all decision. To get it right, you need to match the machine’s mechanics to your specific product and production line. The main point of difference between them is how they actually get the label from the machine onto your product.

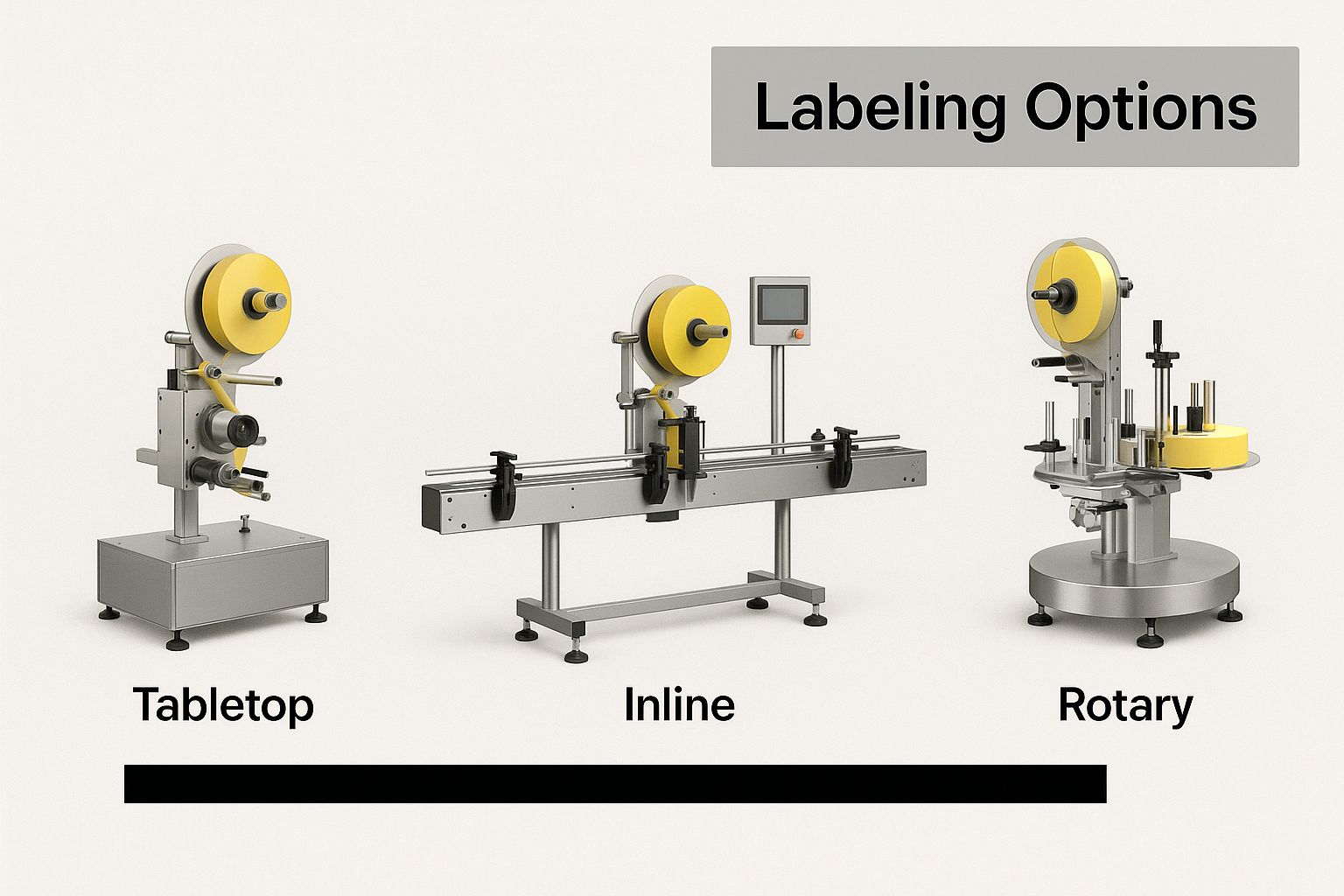

This image gives you a great visual idea of the different shapes and sizes these machines come in, from compact tabletop units to full-scale inline systems for busy production floors.

As you can see, there’s a solution for almost any operational scale. But let’s look into the core methods these machines use to apply the labels.

To help you get a clear picture, this table breaks down the three primary application methods. Think about your product’s shape, fragility, and the speed you need to run at as you review the options.

| Applicator Type | Application Method | Ideal For | Key Advantage |

|---|---|---|---|

| Wipe-On | A brush or roller physically presses the label onto a moving product. | Flat or slightly curved surfaces like boxes, pouches, and jars. | High speed and reliability for consistent surfaces. |

| Air-Blow | A jet of compressed air blows the label onto the product from a short distance. | Delicate items or products with uneven or recessed surfaces. | Completely contactless application, preventing product damage. |

| Tamp-Blow | A pad moves near the product, then a puff of air applies the label. | Precise placement on specific spots or into recessed areas. | Excellent accuracy and placement control. |

Each method has its place on the production line. The key is knowing which one aligns best with your needs, making certain you get a clean, professional finish every single time.

The wipe-on applicator is the trusted workhorse of the labelling world. It’s one of the most common and straightforward designs, and for good reason-it’s incredibly effective.

As your product travels along a conveyor, the machine dispenses a label directly into its path. A roller or soft brush immediately follows, firmly wiping the label down. This action makes certain it adheres smoothly and securely, pushing out any potential air bubbles or wrinkles.

Because of this direct contact, the wipe-on method is perfect for labelling sturdy products with flat or gently curved surfaces, like boxes, flat-sided bottles, and cartons. Its major advantage is its speed and reliability on consistent surfaces, making it a go-to for many high-volume packaging lines. The only real drawback is that the physical contact isn’t suitable for very delicate items or for placing labels into recessed areas.

What if your products are fragile or have an awkward shape? That’s where an air-blow (or blow-on) applicator comes in. This clever system offers a completely contactless way of labelling.

Here’s how it works: the label is peeled from its backing liner and held gently by suction on an applicator grid. A sensor detects the product as it passes, triggering a sharp, precise puff of compressed air. This air-jet propels the label across a small gap, placing it perfectly onto the product’s surface.

This contactless approach is a big deal for delicate items or products with uneven surfaces, where a physical roller could cause damage or apply the label incorrectly.

Since there are no moving parts in the applicator head itself during the cycle, wear and tear is kept to a minimum. It’s a fantastic choice for high-speed lines where product shapes might vary.

The tamp-blow applicator is a smart hybrid, combining the precision of a tamping action with the gentle touch of air-blow. It gives you the best of both worlds.

A flat pad, called a tamp pad, is mounted on a pneumatic cylinder. The machine extends this pad towards the product, stopping just a few millimetres away without ever making contact. Once it’s in position, a jet of air blows the label from the pad and onto the product. This method provides outstanding placement accuracy, making it the ideal solution for applying small labels to very specific locations or for neatly placing labels into recessed areas on packaging.

For businesses just starting to automate, exploring the benefits of semi-automatic labelling can be a great first step before moving up to these more advanced, fully-automated systems.

Beyond these core methods, you’ll find many machines designed to tackle very specific packaging challenges.

The demand for this technology is surging. The global market for label applicators is expected to grow from USD 1.10 billion in 2025 to USD 1.82 billion by 2035. This growth is fuelled by industries here in the UK and beyond-like food and beverage, pharmaceuticals, and logistics-that need to increase production speed and reduce labour costs.

An automatic label applicator is far more than just another piece of equipment; it’s the engine driving efficiency and precision across a surprisingly wide range of UK sectors. These systems are the unsung heroes working behind the scenes, from the food on our dinner tables to the medicines in our bathroom cabinets. They do much more than just stick on a label-they solve specific, critical problems for each industry they serve.

This technology has become fundamental wherever speed, accuracy, and compliance are paramount. Its widespread adoption comes down to one simple fact: it directly tackles major operational headaches like human error, slow production speeds, and the ever-growing burden of regulatory standards.

Let’s take a closer look at a few of the key industries where these machines have become absolutely indispensable.

The food and beverage industry is a world of massive volumes and razor-thin margins. In this environment, an automatic label applicator is not just helpful; it’s necessary for keeping pace and meeting strict food safety laws. Just picture a busy bottling plant or a ready-meal production line-trying to label everything by hand would create an impossible bottleneck.

These machines effortlessly manage several necessary tasks:

For food producers, it all boils down to speed and consistency. An automated system guarantees every single product heading to the supermarket shelf looks professional and meets all the legal requirements for consumer information.

In the world of pharmaceuticals, there is simply no room for error. A single misplaced or misprinted label can have devastating consequences. This is why the pinpoint precision of an automatic label applicator is less of a convenience and more of a critical compliance tool.

The entire focus here is on absolute accuracy and traceability. Every label must be flawless, carrying information that is necessary for patient safety and regulatory oversight.

Pharmaceutical applicators are often highly specialised, built to handle delicate, high-stakes tasks like:

The machines used here are sophisticated pieces of engineering, often designed to work in sterile cleanroom environments and connect seamlessly with complex track-and-trace software.

The logistics industry is the circulatory system of modern commerce. Its efficiency hinges on tracking millions of parcels quickly and accurately every single day. At the heart of any modern distribution centre, you’ll find a print-and-apply automatic label applicator.

As packages speed down sorting conveyors, these systems print a unique shipping label and apply it in the blink of an eye. This label is a passport for the parcel, containing everything from the recipient’s address and a scannable tracking barcode to crucial routing data. Without this level of automation, the promise of next-day delivery that we’ve all come to expect would be completely unachievable.

The UK market certainly reflects these demands. The focus is on high-speed machines that can talk to warehouse management systems in real-time. For massive operations, like those in food and pharmaceuticals, some applicators are capable of labelling over 2,500 items per minute, keeping up with immense production volumes and strict hygiene rules. You can discover more about how technological integration is shaping the UK market for these applicators on marketreportanalytics.com.

Choosing the right automatic label applicator is a major decision for any UK business aiming to get its production line running smoothly. Get it right, and you’ll see a massive boost in efficiency. Get it wrong, and you’ve just bought yourself a constant source of headaches and downtime. Think of this as your practical checklist, designed to help you ask the right questions and find the perfect machine for your needs.

Before you even start looking at brochures or talking to sales reps, the first step is to look inwards. You need a crystal-clear picture of your own operation and what you’ll be asking the machine to do, day in and day out.

It’s your product that really dictates the type of machine you need. It sounds obvious, but you’d be surprised. A labeller designed for flat cardboard boxes is going to be completely useless for labelling curved glass bottles. Start by getting the specifics down on paper.

The environment itself is another huge factor. A dusty, dry warehouse is a world away from a cold, wet bottling facility. You need to examine whether your new labeller requires special housing or construction to protect it from moisture, dust, or extreme temperatures.

Once you’ve got a handle on your own requirements, you can start assessing potential machines and, just as relevantly, their suppliers. Look past the initial price tag and think about the total cost of owning and running the machine over its lifetime.

A great supplier acts more like a partner. They should be focused on solving your production puzzle, not just shifting a box. Their expertise is what will guide you to the genuinely best solution for your business.

It’s also wise to think about the future. Could the machine be adapted for different products or labels if your business pivots? Investing in a flexible system now could save you from having to buy a whole new machine in a few years. By exploring the many advantages of automatic labelling, you can build a solid business case for making this crucial investment. A well-informed decision today will pay for itself many times over in efficiency and reliability for years to come.

The world of automated labelling is far from static. If you think today’s applicators are impressive, the next wave is poised to be much smarter, more connected, and fundamentally more sustainable. These aren’t just incremental updates; they’re direct responses to the real-world demands of modern manufacturing for greater efficiency, total transparency, and genuine environmental responsibility.

A massive driver behind this evolution is the push for intelligent packaging. Soon, a label won’t just sit there displaying information; it will actively communicate. This is where technologies like Near Field Communication (NFC) and Radio Frequency Identification (RFID) technology are changing the game. By embedding these into labels, an automatic applicator gives every single product its own unique digital identity.

Suddenly, you have a world of new possibilities. We’re talking about tracking goods through the supply chain with pinpoint accuracy, offering customers interactive brand experiences with a simple phone tap, and creating powerful, hard-to-beat anti-counterfeiting measures.

Another huge leap forward is the integration of Artificial Intelligence (AI) and machine vision. Imagine an automatic label applicator that checks its own work. Future models will come equipped with high-speed cameras and smart software that can spot a slightly crooked label, identify a tiny printing error, or verify barcode readability in a split second.

This isn’t just a minor tweak. It shifts quality control from a separate, often manual, step into an integrated part of the labelling process itself. The result? A massive reduction in waste and the peace of mind that only perfectly labelled products are making it out the door. These AI-powered systems can also learn on the fly, automatically adjusting their settings for minor variations in products or labels, which cuts down on stoppages and the need for constant operator oversight.

Sustainability has moved from a “nice-to-have” to a core business principle, and this is having a profound impact on the design of the next generation of labelling machines. Applicator manufacturers are now engineering systems specifically to handle greener materials without a hitch.

This includes working with:

The UK’s sustainable label market is a perfect example of this shift. Projections show its value could hit £18 billion by 2025. This growth is directly tied to the demand for machinery that enables green packaging initiatives, as businesses strive to meet both regulatory targets and consumer expectations. You can get a deeper look into how future labelling technology trends are shaping the industry and pushing innovation forward.

This pivot towards greener solutions isn’t just about compliance; it’s a clear response to a market that increasingly chooses environmentally conscious products.

Thinking about investing in an automatic label applicator often brings up a few common questions. Getting these sorted out from the start is the best way to figure out if this technology is the right move for your UK operation and what to expect when it’s up and running.

This really depends on the machine you’re looking at, the type of label, and how it’s being applied. For smaller businesses or less demanding production lines, an entry-level machine will comfortably handle around 20-50 labels per minute.

But if you’re in a high-volume industry like bottling or pharmaceuticals, you’ll be looking at high-performance systems that can fly through over 1,000 labels per minute. The trick is to match the applicator’s speed to your production line’s pace so it keeps things flowing smoothly instead of causing a jam.

Absolutely. Versatility is a huge selling point for most modern labellers. You’ll find that many come with adjustable guide rails, moveable sensors, and adaptable applicator heads, all designed to manage a variety of product shapes and sizes.

That said, some machines are specialists, like wraparound labellers built just for bottles or front-and-back systems for boxes. It is always a good idea to chat with your supplier about everything you produce-and plan to produce-to make sure you get a machine that can grow with you.

One of the most relevant things to think about is changeover time. How long does it take to switch from one product to another? A system that can be adjusted quickly and easily, without needing a box of special tools, will minimise downtime and keep your production line efficient.

The integration process can range from incredibly simple to a bit more involved, depending on your current setup. Standalone applicators, for example, often just need to be wheeled up to your existing conveyor belt. It’s a quick and easy way to get started with minimal fuss.

For more complex systems that need to talk to your other machinery, you might need to make some physical adjustments to the line and wire it into your main control panel. To make life easier, look for applicators with flexible mounting options and standard communication ports. Many suppliers also offer full installation and integration services to get you going.

Keeping a label applicator in good shape is mostly about simple, regular checks. A little routine care goes a long way in making certain it runs reliably day in and day out. This typically involves:

Your manufacturer will provide a maintenance schedule. Sticking to it is the best way to dodge common operational headaches and get the longest possible life out of your machine.

For expert guidance on selecting and integrating the perfect Sessions UK labelling machine for your business, explore our full range of labelling machinery.

Copyright © 2026 Sessions Label Solutions Ltd.