A bottle label maker isn’t just another piece of machinery; it’s the final, critical step in dressing your product for success. Think of it as the specialist that makes sure every single bottle leaves your facility wearing a perfect and consistent uniform, making it instantly stand out on a crowded shelf. This machine is your brand’s most reliable storyteller.

A professionally applied label does far more than just say what’s inside. It speaks volumes about quality, builds trust, and sets a customer’s expectations before they’ve even twisted the cap. The precision of a machine-applied label sends a clear signal of professionalism, something people naturally connect with a higher-quality product.

Picture two bottles of craft gin on a shop shelf. One has a label that’s slightly askew, with a few air bubbles trapped underneath. The other boasts a perfectly smooth, straight label, applied with mechanical precision. Right away, that second bottle projects an image of care and quality, which can make all the difference at that critical moment of choice.

Every single detail on your label helps to tell your brand’s story. A cleanly and accurately placed label is the opening chapter, suggesting that you pay close attention to every part of your business. This first impression is incredibly powerful and can be the deciding factor that makes a customer choose your product over a competitor’s. A bottle label maker makes sure that first impression is always a strong one.

A professional label delivers some key advantages:

Your label is your product’s first handshake with the consumer. It needs to be firm, confident, and professional. An automated labelling process is the best way to guarantee that handshake is perfect every single time.

Beyond just looking good, precise label placement is a legal must-have in many industries. In sectors like pharmaceuticals or health supplements, labels carry important information that has to be clear and correctly positioned. A huge part of this is mastering supplement label requirements to stay compliant and earn consumer confidence.

Putting money into the right equipment isn’t just about getting things done faster. It’s about taking control of how your brand is seen from the very first glance. This sets the stage for exploring the different types of machines, what they’re used for, and how you can pick the one that’s the right fit for your business.

Picking the right bottle labeller is one of those decisions that can genuinely shape your business’s future. It directly affects how fast you can get your products out the door, the consistency of your branding, and your overall efficiency. Your choice boils down to three main types: manual, semi-automatic, and fully automatic.

Each one is built for a different stage of business, from the kitchen table artisan to the sprawling factory floor. Understanding how they work, who they’re for, and what they cost is key to finding the perfect match for your production needs today-and your ambitions for tomorrow. This is more than just sticking labels on bottles; it’s about investing in a system that can grow with you.

Manual label applicators are your first step into the world of professional labelling. Think of them less as a machine and more as a high-precision hand tool. You operate them yourself, placing each bottle into a jig and then turning a crank or pulling a lever to wrap the label around it. The magic is in the rollers, which make sure the label goes on straight and smooth every single time. It’s a world away from the frustration of trying to do it all by eye.

These are perfect for businesses just starting out.

The biggest wins here are the low upfront cost and tiny footprint. It’s an accessible way to get a professional finish without a hefty financial commitment.

As your business picks up steam, you’ll quickly find that manual labelling just can’t keep up. It becomes a real bottleneck. That’s where semi-automatic bottle label makers step in. These machines are the perfect middle ground, giving you a smart mix of mechanised speed and hands-on control.

You still place each bottle onto the machine, but from there, a simple tap of a footswitch or a wave past a sensor kicks off the process automatically. The machine handles the tricky parts, dispensing and applying the label with perfect pressure and placement every time.

This machine is the true workhorse for most growing businesses. They neatly bridge the gap, letting you scale up production without needing the massive investment and space a fully automated line demands. For a closer look at these versatile systems, you can find great information on semi-automatic labelling machines.

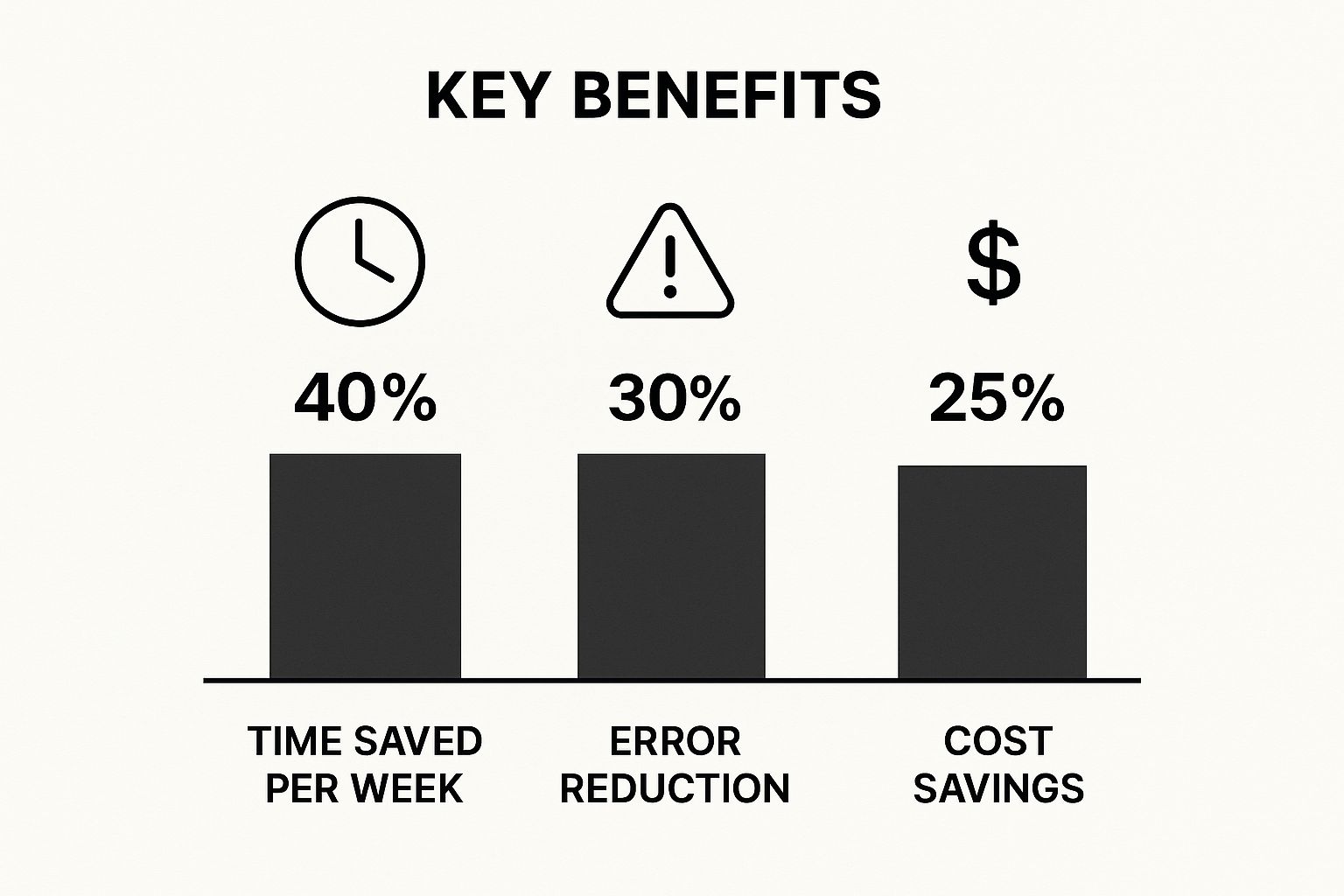

The right equipment upgrade can have a huge impact, as this graphic shows.

As you can see, making the jump to a more automated system pays off quickly in time saved, fewer errors, and better cost control.

When you’re dealing with serious volume, only a fully automatic system will do. These machines are engineered to slot right into a complete production line. Bottles cruise along a conveyor belt, and the labeller applies labels at high speed with zero human help. Sophisticated sensors detect each bottle, apply the label in a fraction of a second, and send it down the line to the next station.

These systems are built for one thing: maximum output with minimal human input. They’re the industry standard for beverage giants, pharmaceutical companies, and mass-market cosmetics brands that churn out thousands of units every single day.

Fully automatic machines are all about impressive numbers and capabilities.

The investment is significant, of course. You’ll need dedicated floor space and technical know-how to run and maintain it. But for any high-volume operation, the return on investment from savings on labour and massive gains in throughput is a no-brainer.

To make the choice a bit clearer, let’s break down how these three types stack up against each other.

| Feature | Manual | Semi-Automatic | Fully Automatic |

|---|---|---|---|

| Speed | 100-250 bottles/hr | 500-1,500 bottles/hr | 2,000-10,000+ bottles/hr |

| Operator Input | Constant | Load/unload each bottle | Supervisory only |

| Consistency | Good, but operator-dependent | Very high | Flawless |

| Initial Cost | £ | ££ | £££££ |

| Footprint | Very small (desktop) | Small (benchtop) | Large (production line) |

| Best For | Start-ups, artisans | Growing businesses, contract packers | Large-scale manufacturing |

This table highlights the trade-offs. As speed and automation increase, so do the cost and complexity. The key is to find the sweet spot that matches your current production demands while leaving a little room to grow.

Today’s consumers are savvier than ever. They don’t just grab a product off the shelf; they’re buying into a brand’s story, its values, and its promise to the planet. This fundamental shift has turned the humble bottle label into one of the most important communication tools you have.

Suddenly, choosing the right bottle label maker isn’t just about how fast it can run. It’s about keeping pace with these complex, ever-evolving market demands. Modern shoppers expect total transparency. They want the full story: where the ingredients came from, how the product was made, and what you’re doing to reduce your environmental impact. A high-quality, accurately applied label is your first and best chance to deliver that information.

In the UK, sustainability isn’t a buzzword; it’s a major driver of purchasing decisions. Shoppers are actively hunting for products packaged in recycled or biodegradable materials. This presents a new, practical challenge for producers, as these eco-friendly materials often have different surface textures and properties compared to traditional glass or virgin plastics.

Think about it. A label that sticks perfectly to a standard PET bottle might completely fail on a bottle made from 100% recycled PET (rPET), which can have tiny surface imperfections. This is where modern bottle label makers really shine. They’re built to handle these variables, offering precise control over application pressure and speed to make sure labels go on smoothly, without a single wrinkle or bubble, no matter the material.

The UK’s plastic bottle market, valued at around USD 562.20 million in 2025 and projected to hit USD 648.27 million by 2030, is being pushed forward by this very demand. We’re seeing major players adapt in real-time. For instance, in April 2024, Aldi moved its entire own-brand soft drinks range to 100% recycled PET bottles. This isn’t just a headline; it’s a clear signal that your labelling equipment has to keep up with the times.

The thirst for information doesn’t end with sustainability. Consumers want detailed nutritional data, clear allergen warnings, and sometimes even proof of authenticity. This has led to the rise of more complex labels, often integrating QR codes that link to a website for more information.

For businesses needing to track products through the supply chain or create interactive experiences, advanced labelling is needed. This is where technologies like RFID enter the picture, embedding tiny trackers directly within the label. If you’re curious, you can learn more by checking out our guide on what RFID labels are and how they work.

A modern labelling machine isn’t just an applicator; it’s a tool for market relevance. It makes sure that your packaging can adapt to new materials, carry more complex information, and meet the expectations of an ever-smarter consumer base.

Investing in the right labelling equipment is a direct investment in your brand’s future. It makes sure your product not only looks professional on the shelf but also speaks directly to the values of the customers you want to reach.

It’s one thing to talk about the mechanics of these machines, but where do they really prove their worth? The answer is out in the real world, solving practical problems for businesses every single day. Bottle labellers aren’t just another piece of equipment; they’re needed for branding, complying with regulations, and keeping production lines moving smoothly.

Every industry has its own set of challenges, and the right labelling machine is built to tackle them. Let’s take a look at how these machines perform in some of the most demanding sectors.

Walk into any shop, and you’ll see the beverage aisle is a battlefield for attention. Here, the label does most of the talking. For a craft brewery, a small-batch distillery, or a boutique winery, a unique, perfectly applied label can be the difference between standing out and getting lost in the crowd. The big hurdle is getting a flawless, wrap-around application on cylindrical bottles, which can be surprisingly tricky.

This is where a semi-automatic bottle labeller becomes a craft producer’s best friend. It delivers the speed needed for growing production runs without sacrificing that premium, hand-applied look. These machines eliminate the wrinkles, bubbles, and wonky placements that can instantly cheapen a product’s appeal. If you’re deep in the world of brewing, our detailed guide on printing labels for beer bottles is packed with useful insights.

Labels in this industry have a rich history, too. In the UK, lagers first started appearing in pubs around the 1950s but didn’t really take off until the 1970s. As their popularity grew, bottle labels evolved right alongside them, becoming a crucial part of a brand’s identity in an ever-expanding market.

In the food world, a label has to work twice as hard-it needs to look appealing while also being packed with information. For products like sauces, oils, and jams, labels are the home for ingredient lists, nutritional facts, and critical allergen warnings. The main challenges here are dealing with all sorts of container shapes and making sure the label stays put, whether it’s in a cold fridge or a warm pantry.

Bottle labelling machines bring the precision needed to meet strict food safety rules. A crooked label isn’t just a cosmetic flaw; it can hide important information and create serious compliance headaches. That’s why high-volume producers often turn to fully automatic systems to guarantee every single jar is labelled perfectly before it ever hits a shelf.

For cosmetics, looks are everything. The packaging is a direct promise of the quality inside. Think about lotions, serums, and moisturisers-they often come in small or unusually shaped bottles that need precise front-and-back labelling. To achieve that premium feel, the labels have to be perfectly aligned.

This is a job for specialised labellers. They use sophisticated sensors and applicators to place separate front and back labels with pinpoint accuracy. This is absolutely necessary for creating the polished, high-end look that customers expect when they’re buying beauty and personal care products.

For cosmetic products, the label isn’t just part of the packaging; it is the packaging. A flawless application communicates luxury and attention to detail, which is exactly what the beauty consumer is looking for.

When it comes to pharmaceuticals and chemicals, there is absolutely no margin for error. A label carries life-or-death information: dosages, batch numbers, expiry dates, and safety warnings. The top priorities here are accuracy, security, and compliance with incredibly strict regulations.

Pharmaceutical-grade labelling machines are built for this high-stakes environment. They do much more than just stick on a label:

In these industries, a bottle labeller isn’t a convenience-it’s a critical tool for public safety and maintaining the licence to operate.

Choosing the right bottle label maker can feel like a huge decision, and frankly, it is. This isn’t just another piece of kit you’re buying; it’s a real investment in your brand’s consistency, speed, and professional finish. When you start looking, the technical specs can seem a bit bewildering, but they’re really just signposts pointing you toward the best machine for your specific setup.

This guide is here to demystify the whole process. We’ll cut through the jargon and turn it into simple, practical decision points, helping you build a checklist of what truly matters for your operation. Get this choice right, and you’ll have a machine that not only keeps up with today’s demand but also grows right alongside your business.

The very first question you need to ask is simple: how many bottles are you labelling per hour? Your answer will immediately point you towards either a manual, semi-automatic, or fully automatic machine. Be realistic about your current output, but don’t forget to look ahead and think about where you want to be in the next 12 to 24 months.

A small-batch producer carefully labelling 50 bottles an hour has entirely different needs from a contract bottler pushing for 1,000 an hour. Nailing down your production speed is the most effective first step to filtering your options.

Not all bottles and labels are created equal. The physical shape and size of your packaging play a huge role in what kind of machine you’ll need. A simple applicator designed for standard cylindrical beer bottles just isn’t going to work for tapered wine bottles or square-sided gin bottles without the right adjustments.

Take stock of the containers you’re using now, and also think about any new formats you might want to introduce down the line. If your product range is diverse or likely to expand, versatility is a massive plus.

The shape of your bottle and the style of your label aren’t just aesthetic choices-they’re mechanical requirements. Your machine must be physically capable of handling your specific packaging to deliver a flawless result every single time.

You need to get crystal clear on your requirements.

Questions About Your Bottles:

Questions About Your Labels:

A new machine needs a home, and it’s best to sort that out before it arrives. Get the tape measure out and see what kind of workspace you actually have available. A manual applicator might just sit on a small table, but a fully automatic system needs dedicated floor space and may need to be integrated into an existing conveyor line. Always double-check the machine’s footprint and the recommended operating area.

Finally, think about who will be using it. Manual and semi-automatic models are typically quite straightforward and don’t require much training. Fully automatic systems are more complex. They need operators with the technical know-how to handle setup, product changeovers, and routine maintenance. Factoring in the required skill level from the start will make for a much smoother transition once your new machine is on the floor.

Bringing a dedicated bottle label maker into your operation isn’t just about tweaking your production line-it’s a strategic move that directly hits your bottom line and shapes how customers see your brand. Moving away from hand-labelling to an automated system delivers real, measurable improvements, from the factory floor right through to the shop shelf. It’s about building a more professional, efficient, and reliable business.

Think about a small, artisan sauce company. When they label every jar by hand, it’s slow, inconsistent, and eats up hours that could be better spent elsewhere. The labels might be a little crooked or have tiny bubbles, subtly hinting at an amateur setup. Now, imagine they switch to a semi-automatic machine. Suddenly, their output doubles. Every single jar boasts a perfectly placed, smooth label, reflecting a high-quality product that commands a better price.

The first thing you’ll notice is a huge leap in speed and a drop in labour costs. A machine applies labels far quicker than any person can, freeing up your team to focus on more important tasks. This efficiency boost means you can finally say yes to larger orders and grow your business without manual finishing holding you back. To get a clearer picture of the investment, it’s worth exploring the different labelling machine price and cost components to see how it all adds up.

This consistency also does wonders for brand trust. When every product on the shelf looks exactly the same, it sends a powerful message of reliability and professionalism. Fewer mistakes in application mean less wasted stock and a stronger, more dependable brand image in the eyes of your customers.

Let’s not forget that accurate labelling is often a legal requirement. In sectors like food and drink, labels have to clearly display detailed nutritional information and allergen warnings. With UK food regulations constantly evolving-from mandatory nutritional data in the 1970s to stricter allergen declarations today-precision is non-negotiable.

A dedicated bottle label maker makes sure that critical information is always correctly applied, helping you meet legal standards and protect consumers. Misaligned or obscured information is not just a cosmetic issue; it’s a compliance risk.

At the end of the day, a quality machine is the heart of your finishing process. It works hand-in-hand with your wider quality assurance framework in manufacturing to make sure every single bottle that leaves your facility is a perfect ambassador for your brand.

Even after you’ve grasped the basics, it’s natural to have a few practical questions when you’re on the verge of choosing a machine. Getting these points cleared up can be the final step in feeling confident about your investment.

Think of this section as a quick Q&A, tackling the most common queries we hear from business owners just like you.

Absolutely. A lot of modern semi-automatic and automatic labellers are designed with versatility in mind. They come with adjustable guides, rollers, and sensors that you can move around to fit various bottle diameters and heights.

The key word here is versatility, and it really depends on the model. Some machines are specialists, built only for simple cylindrical bottles. Others are true all-rounders, capable of labelling square, oval, and even tricky tapered containers once they’re set up properly. Always double-check the machine’s specifications to make sure it can handle the bottles you’re using now and any you might introduce later on.

The maintenance really comes down to the machine’s complexity. A simple manual labeller is quite low-maintenance and might just need a quick wipe-down now and then to keep it working well.

Step up to a semi-automatic or automatic machine, and you’ll need to be a bit more proactive. Regular care often involves cleaning adhesive gunk off the rollers and sensors, keeping an eye out for wear and tear on parts like belts, and making sure the sensors are properly calibrated for pinpoint accuracy. Good manufacturers will give you a clear maintenance schedule, which is your best bet for avoiding unexpected downtime.

Yes, this is a big one. Bottle label makers don’t use sheet labels like you’d put in an office printer. They need labels supplied on a roll, and they have to be oriented in a specific way – something the industry calls ‘wind direction’.

Your label supplier will need to know a few key details: the gap size between labels, the diameter of the roll’s cardboard core, and the maximum outer diameter of the finished roll. These specs have to match your machine perfectly for it to work.

You’ll need to partner with a label printer who understands these requirements. They can produce rolls tailored to your machine, which is the secret to a jam-free, efficient labelling process.

The footprint can vary massively from one machine to another. A manual applicator is tiny and can easily live on a tabletop, making it perfect for small workshops or start-ups.

Semi-automatic models are often benchtop-friendly too, but you’ll want a bit of elbow room around them for the operator. The fully automatic systems are the largest of the bunch. They’re designed to slot into a full production line and often come with their own conveyor belts, so they need a dedicated slice of your floor space. Before you buy anything, get the tape measure out and check the machine’s dimensions against what you’ve got available.

At Sessions UK, we provide the expertise and equipment to help your business achieve a professional finish. Explore our full range of bottle labelling machines to find the perfect solution for your production needs.

Copyright © 2026 Sessions Label Solutions Ltd.