Walk down any supermarket aisle, and you’ll see it in action: every jar, bottle, and box is perfectly labelled. That’s the work of food labelling machinery, the unsung hero of the food production line. It’s the equipment that automates applying labels to packaging, acting as the final, critical touchpoint before a product meets the customer.

This machinery is responsible for everything from brand consistency and communicating legally required information to tracking products as they move through the supply chain. Think of it as your product’s storyteller, getting the right information in the right place, every single time.

At its heart, food labelling machinery is any equipment designed to apply labels to products, containers, and packages. It’s the difference between a hand-stuck, slightly crooked label on a farmer’s market jam jar and the perfectly aligned, information-packed label on a supermarket ready meal.

These machines handle an incredible variety of tasks. They can apply a simple brand logo to the front of a bottle or a complex, data-heavy label with barcodes, nutritional information, and critical allergen warnings to the back of a packet.

This isn’t a one-size-fits-all world. The technology scales dramatically with the size of the business. For a small artisan producer, it might be a simple tabletop device that just offers a step up in consistency from doing it all by hand. For a large-scale food manufacturer, it’s a high-speed, fully automated system woven directly into the production line, capable of precisely labelling thousands of products an hour.

The importance of good labelling equipment goes way beyond just sticking things on. It’s central to both operational efficiency and legal compliance. A single misplaced or poorly printed label can trigger costly product recalls, attract fines from regulators, and do serious damage to a brand’s hard-won reputation.

Modern food labelling machines are built to solve these problems. They deliver:

It’s no surprise that more businesses are investing in this technology. The UK labelling equipment market is set to grow at a compound annual growth rate of around 4.9% between 2025 and 2035. This growth is being pushed largely by the food industry’s demand for high-precision systems that can meet increasingly strict safety and branding standards. You can examine these market trends in the full report from Future Market Insights.

A food labelling machine is the bridge between your product and your customer. It communicates your brand’s story, ensures safety, and builds consumer trust through clear, accurate, and professional presentation.

Getting to grips with the different levels of automation is the first real step in figuring out what your business needs. Whether it’s a manual tool for a startup or a sophisticated integrated system for a massive factory, the right machine can completely change your production process for the better.

Picking the right food labelling machine is like choosing a vehicle. A local baker delivering pastries across the road doesn’t need a massive articulated lorry, just as a national logistics firm can’t run its entire operation with a small van. It’s all about matching the tool to the scale of the job.

Labelling automation is no different. It falls neatly into three distinct tiers: manual, semi-automatic, and fully automatic. Understanding where you fit is the first step to finding a solution that matches your production volume, budget, and future plans. Each level serves a specific purpose, offering a clear path for a business to follow as it grows.

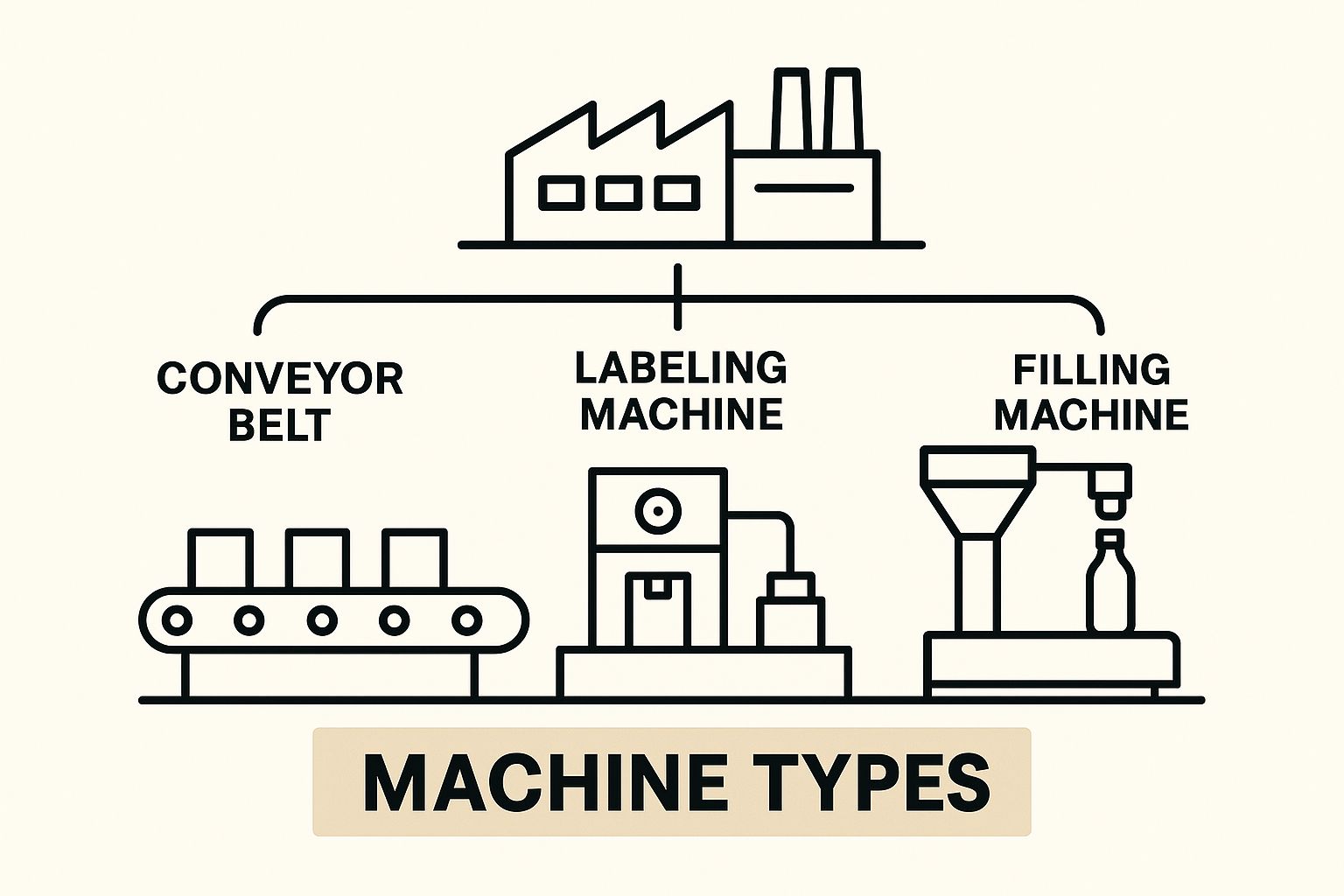

The image below gives a great visual breakdown of how these machine types fit into a modern production environment.

As you can see, the systems range from simple tabletop units for small batches all the way up to complex, integrated machinery designed for a non-stop factory floor.

For most artisan producers and market startups, this is where the journey begins. Manual labellers are simple, often hand-held or hand-cranked devices that bring a touch of consistency to what was once a purely by-hand task. They’re a huge step up from peeling and sticking labels one by one, a process that’s often slow and riddled with human error.

Picture a local beekeeper selling a few hundred jars of honey a month. Trying to apply each label by eye is a recipe for crooked, bubbly results that look unprofessional. A basic manual bottle labeller makes certain every single jar looks identical and sharp, helping to build a credible brand without a hefty initial investment.

These machines are perfect for:

They’re incredibly user-friendly, require almost no setup, and are small enough to sit on a workbench. While they won’t break any speed records, they deliver the precision needed to give small-batch products that polished, professional finish.

As a business starts to take off, the need for more speed and efficiency becomes obvious. This is where semi-automatic food labelling machinery steps in. These machines are the practical sweet spot, bridging the gap between slow manual work and full-blown automation. The process still needs an operator to place the product onto the machine, but the labelling itself is mechanised.

Take a growing craft gin distillery, for instance. They might graduate from a hand-cranked device to a semi-automatic model. The operator simply places a bottle into a jig, taps a footswitch, and the machine wraps the label perfectly every time. This one change can boost output from a couple of hundred units an hour to well over 1,000.

A semi-automatic labeller takes the guesswork out of applying labels, delivering consistent placement at a much faster pace than manual methods. It allows a business to scale up production without the cost and complexity of a fully automated line.

This tier is ideal for businesses that are expanding but aren’t quite ready for a complete production line overhaul. They offer a fantastic balance of speed, accuracy, and operator control, making them a very popular choice for medium-sized operations. You can get even more out of them by pairing them with a dedicated food label printer to handle variable data like batch codes and best-before dates on the fly.

At the very top of the ladder, you’ll find fully automatic food labelling machinery. These are the workhorses of large-scale manufacturing, where thousands of products cruise along conveyor belts every hour. Unlike their smaller cousins, these machines are integrated directly into a production line and operate without any human intervention beyond the initial setup and routine checks.

Think of a national soft drinks company bottling thousands of drinks a minute. A fully automatic wrap-around labeller applies labels as the bottles speed past, never once slowing the line down. These systems are built for high-volume, 24/7 operation and offer unmatched speed and accuracy.

They often come packed with advanced features, such as:

An automatic system is a serious investment, but for any high-volume producer, the return on that investment is undeniable. They slash labour costs, virtually eliminate errors, and push throughput to the maximum, making them a core part of modern food manufacturing.

To help you visualise where your business fits, the table below breaks down the key differences between the three tiers. It’s a straightforward comparison to help you weigh up the best option based on your production volume, budget, and operational needs.

| Feature | Manual Labellers | Semi-Automatic Labellers | Automatic Labellers |

|---|---|---|---|

| Speed/Volume | Low (up to 500 units/hour) | Medium (500 to 1,500+ units/hour) | High (1,500 to 10,000+ units/hour) |

| Operator Input | High (Operator performs each action) | Medium (Operator loads product, machine applies label) | Minimal (Integrated into a production line) |

| Consistency | Good (Better than by hand) | Excellent (Mechanically precise) | Flawless (Sensor-driven precision) |

| Cost | Low (Entry-level investment) | Moderate (Balanced cost-to-performance) | High (Significant capital investment) |

| Ideal For | Startups, artisans, product testing, very small batches. | Growing businesses, medium-volume producers. | Large-scale manufacturers, high-speed production lines. |

The choice between these three tiers comes down to where your business is today and where you plan for it to be tomorrow.

Automatic food labelling machinery isn’t just one type of kit; it’s a whole family of specialised equipment. Think of it like a chef’s knife collection – you wouldn’t use a cleaver for delicate paring, and you wouldn’t use a standard labeller for a uniquely shaped bottle. Each machine is engineered to solve a specific packaging challenge.

Getting to grips with the main types helps to clear up the jargon and makes it far easier to match the right system to your product.

Whether you’re working with round bottles or flat-topped trays, the container’s shape is the deciding factor. The end goal is always the same: apply a label perfectly, every single time, at a speed that keeps your production line humming along without a hitch.

Walk down any supermarket aisle, and you’ll see countless bottles and jars with a single label wrapped flawlessly around them. That’s the handiwork of a wrap-around labeller. As the name suggests, this machine is the specialist for anything cylindrical.

Picture a jar of pasta sauce or a bottle of juice moving along a conveyor. It gets gently held by a wrap belt as the machine dispenses a label. The belt then rolls the container, wrapping the label smoothly and precisely around its body. The result is a professional finish with no wrinkles or bubbles in sight.

This is the go-to equipment for products like:

The mechanics are brilliantly simple but incredibly effective. These machines are built for speed, often handling thousands of units per hour, making them a true workhorse for any high-volume beverage or food producer.

Lots of food products, particularly fresh items, come in trays, punnets, or clamshells. A wrap-around system is no use here. This is where top and bottom labellers step in. These systems are set up with two separate labelling heads – one above the conveyor and one below.

As a tray of minced meat or a clamshell of berries passes through, the top head applies a label to the lid, while the bottom head simultaneously sticks one to the base. This dual action is perfect for showing off branding on top while keeping the nutritional information, barcodes, and ‘use by’ dates neatly on the bottom.

A key benefit of top and bottom systems is their ability to apply two different labels in a single pass. This improves efficiency and is ideal for products requiring extensive information for regulatory compliance.

You’ll see these machines commonly used for fresh produce, ready meals, and bakery goods. Their versatility allows them to handle all sorts of flat or slightly curved surfaces, making them a flexible solution for many food packers. The investment for such machinery can vary, so it helps to understand the moving parts. To get a clearer idea, have a look at our guide on what determines labelling machine price and cost components.

What about non-cylindrical containers, like a square bottle of olive oil or an oval-shaped bottle of lotion? For these, you often need separate front and back labels. A front and back labeller is designed for exactly this, using two opposing labelling heads to apply both labels at the same time as the product moves past.

The machine uses clever spacing wheels or belts to make certain each container is lined up perfectly before it meets the labelling heads. This precise alignment means the front label (usually for branding) and the back label (for ingredients and legal info) are applied straight and centred every time.

This type of machine is ideal for:

The ability to handle two-sided labelling is invaluable for any brand that wants to present a clean, attractive front face while providing all the necessary details on the back.

In many food production lines, labels need to carry unique, real-time information. We’re talking about batch codes, expiry dates, weights, or shipping details that change from one item to the next. A standard pre-printed label just won’t cut it. This is a job for a print and apply labelling system.

These machines have a printer built right into the applicator. As each product comes down the line, the system prints the specific variable data onto a blank or partially printed label just moments before applying it. This “just-in-time” approach is incredibly efficient and drastically cuts down on label waste.

For example, a meat packing plant uses these systems to print a unique weight and price for each individual pack. A logistics hub relies on them to apply shipping labels with unique addresses to every carton. For traceability and logistics, where every single package needs its own distinct identity, these systems are absolutely critical.

Navigating the world of food labelling in the UK isn’t just about making your product look good-it’s about staying on the right side of the law. These rules are far from optional; they’re strict legal requirements designed to keep consumers safe. One small mistake can lead to costly product recalls, hefty fines, and, worst of all, a serious blow to your brand’s reputation.

The bedrock of these rules is the UK Food Information Regulations. This legislation sets out exactly what information needs to be on a food label, how it must be displayed, and even the minimum font size to make people can actually read it. It covers everything from the name of the food to its net quantity and how to store it safely.

This is where the right food labelling machinery becomes an invaluable part of your operation. Trying to apply labels by hand is a recipe for human error, but a good automated system gets it right every single time. It helps you meet your legal duties without putting the brakes on your production line.

The list of what you must include on your labels is very specific. Getting every single element right isn’t just about compliance; it’s fundamental to building trust with your customers. The accuracy of this information is non-negotiable, especially when it comes to health and safety.

Here are some of the most critical details you can’t afford to get wrong:

Juggling all this variable data is one of the biggest headaches for food producers. This is where modern food labelling machinery, especially print-and-apply systems, truly shines. They can print unique dates, batch codes, and specific allergen details onto each label just moments before application, guaranteeing total accuracy.

To get a better handle on what’s coming down the track, it’s wise to stay informed. You can get more information with our complete guide on understanding label regulations for 2025 for production teams and get your operation ready for the future.

Trying to meet these complex rules consistently across thousands of products is a near-impossible task to do by hand. Automated machinery brings a level of precision that manual processes simply can’t match.

For instance, a sophisticated system can be programmed to switch between different label formats for products heading to Great Britain, Northern Ireland, or the EU-each of which has its own slightly different set of rules. This kind of agility is what keeps you compliant and competitive.

It’s this need for precision and flexibility that’s fuelling growth in the market. The global labelling machine market is expected to be worth around USD 12.1 billion in 2025, climbing to an estimated USD 16.7 billion by 2035. In the UK, this trend is largely driven by the food sector’s constant need to comply with evolving regulations and adapt to a post-Brexit world.

Food law is never set in stone. Regulations are regularly updated to reflect new scientific knowledge, public health priorities, and shifting trade agreements. As a business, you need solid processes in place to monitor these changes and adjust your labelling strategy on the fly.

This is why investing in flexible food labelling machinery is such a smart, forward-thinking move. A machine that can effortlessly handle different label sizes, materials, and print variable data gives you a degree of future-proofing. It allows you to adapt your packaging and labelling information quickly whenever new legal demands arise, turning a potential compliance nightmare into a straightforward operational task.

Choosing the right food labelling machine isn’t just about speed or the shape of your bottle. The very materials you use-for both your packaging and your labels-are a huge part of the puzzle. Think of it like picking the right tyres for a car; the slicks that are perfect for a smooth, dry racetrack would be a disaster on a muddy country lane.

https://www.youtube.com/embed/ee_j9FE_WNc

There’s a delicate science at play between the label’s adhesive, the label material itself, and the surface of your product. A machine has to apply the label with just the right amount of pressure and accuracy to make it stick properly. For example, an applicator designed for smooth, rigid glass jars might completely mangle the job on a flexible, textured, vacuum-sealed pouch, leaving you with wrinkles and labels that just won’t stay put.

This is precisely why getting to grips with your packaging’s properties is so important. Different systems are built to solve specific material challenges, whether you’re working with hard plastics and metals or soft films and papers.

Not all surfaces are created equal in the world of labelling. Some are a dream to work with, while others demand a more specialised touch from your food labelling machinery. A simple wipe-on applicator might be all you need for flat cardboard boxes, but try that on a delicate, thin-walled plastic container and you could end up crushing it. That’s where a non-contact blow-on system would be the smarter choice.

Here are a few common material considerations to keep in mind:

The big push towards sustainability is changing the food packaging world, and that has a direct knock-on effect on machinery choices. Both government policies and changing consumer expectations are nudging businesses away from single-use plastics and towards greener alternatives. This shift presents brand-new challenges for labelling equipment.

In the UK, a major catalyst is the Plastic Packaging Tax, which came into effect in 2022. It levies a tax on any plastic packaging that contains less than 30% recycled content. This has prompted many businesses to invest in food packaging and labelling machinery that can confidently handle materials like recycled plastics, paperboard, and biodegradable films. As you can find out in more detail from Grandview Research’s report on the UK food packaging market, opting for greener packaging means your equipment has to keep up with these new environmental standards without sacrificing production efficiency.

Choosing a versatile machine is an investment in your business’s future. A system capable of handling different materials-from traditional plastics to emerging eco-friendly options-makes certain you can adapt to market trends and regulatory changes without needing a complete equipment overhaul. This adaptability is key to long-term operational success.

Picking the right food labelling machine is one of those big decisions that can really make or break your production line. Get it right, and you’ll see a boost in efficiency and product presentation. Get it wrong, and you could be stuck with an expensive piece of kit that just doesn’t fit your needs.

The key is to avoid jumping in feet first. By taking a step back and methodically looking at your operation, you can turn a daunting choice into a clear, logical process. It’s not just about what you need this week, but where you see your business heading over the next few years.

First, you need to get a handle on your numbers. How many products are you labelling in an hour or over a full shift? This single figure will do more to narrow down your options than anything else.

Once you’ve got the technical specs sorted, it’s time for a reality check. You need to consider the real-world constraints of your facility and your budget. These practical points are just as crucial as the machine’s speed and capabilities.

Thinking about your future needs is crucial. A machine that only just meets your current demand leaves no room for growth. Choosing equipment with slightly more capacity than you need right now provides a buffer for expansion and prevents needing another upgrade in just a year or two.

Make sure you cover these logistical bases:

Even with all the details covered, a few practical questions always pop up when you’re getting ready to invest in new equipment. Let’s tackle some of the most common queries to clear up any lingering uncertainties.

Think of it like a car – regular upkeep is non-negotiable for a long, productive life. For most semi-automatic and automatic machines, a quick daily clean to remove any adhesive build-up and dust is a great habit to get into.

Beyond that, you’ll want to schedule a more thorough service every six months to a year, depending on how hard you run it. This is when you’d check and replace any wear-and-tear parts like rollers or drive belts. A little preventative care goes a long way in avoiding surprise breakdowns and expensive repairs.

Absolutely. In most cases, getting a new labeller to talk to your existing equipment is surprisingly straightforward. Modern automatic machines are built to be flexible and usually come with standard inputs and outputs (I/O) that connect with the rest of your production line, from fillers and cappers to conveyors.

When you’re talking to a supplier, make sure to walk them through your current setup. They’ll be able to guide you on the best way to integrate the new machine, making certain everything works together as one smooth, efficient system.

With proper care, a well-made food labelling machine is a solid long-term investment. You can realistically expect a high-quality automatic labeller to serve you well for 10 to 15 years, sometimes even longer.

Its longevity really boils down to three things: the build quality, how intensively it’s used, and the consistency of your maintenance schedule.

Looking at the big picture of operational costs, it’s also worth considering how other systems impact overall efficiency. For instance, implementing smart energy monitoring for food manufacturing can uncover savings that contribute to your bottom line, complementing the efficiency gains from new machinery.

Ready to find the perfect labelling solution for your production line? The expert team at Sessions UK is here to help you navigate your options and choose the right machine for your specific needs. Explore our full range of labelling machines and take the next step towards greater efficiency and professionalism.

Copyright © 2026 Sessions Label Solutions Ltd.