Food labelling printers are not typical office machines. They are specialised bits of kit, built to create clear, tough labels that can handle everything from refrigeration and moisture to constant handling. For any food business, they are a foundational tool, making sure crucial information stays readable all the way from your kitchen to the customer’s hands.

A smudged, peeling label on your product is not just a minor annoyance. It is a genuine risk to your brand’s reputation and, more importantly, your customers’ safety. Standard office printers just are not cut out for the challenging environments of kitchens, production lines, and shop displays. Their ink often runs at the first sign of condensation, and paper labels can easily tear or fall off in transit.

This is where a dedicated food labelling printer comes in. It is not just another piece of hardware; it’s a central part of your quality control and brand presentation. These machines are engineered from the ground up to produce labels that last.

Picture a pre-packaged sandwich in a chilled display cabinet. If its label was printed on a standard office machine, it could become an unreadable mess within hours because of the moisture. That can mean lost sales and frustrated customers who cannot see the ingredients or price.

A specialised food label printer uses specific technologies and materials to produce labels that stand up to these tough conditions. The result? Consistently clear, professional-looking information that protects your brand and builds trust with your customers.

Key durability benefits include:

A label is your direct line of communication with the customer at the point of sale. If that message is compromised by poor quality, the perception of the product itself suffers. A reliable printer is an investment in that communication.

Beyond looking good, food labels carry legal and safety information. Getting these details wrong- or having them become illegible- can lead to serious consequences, from expensive product recalls to actual harm to consumers. Food safety regulations require that ingredient lists, allergen warnings, and date marks like ‘use-by’ or ‘best-before’ are always clearly visible.

A purpose-built food labelling printer is designed to meet these strict standards. It produces high-resolution text and barcodes that are easy to read, helping you stay compliant. Whether you’re a small bakery that needs to get allergen information right or a large factory tracking batches, the right printer is fundamental to a safe operation. It turns a simple label into a guarantee of transparency and safety.

For businesses that want a deeper understanding of the options available, you can learn more about choosing your ideal food labels printers in our detailed guide.

Choosing the right food labelling printer starts with getting to grips with the core technology inside. Think of it like a chef’s kitchen- you would not use a bread knife to fillet a fish. In the same way, different printers are designed for very specific jobs. When it comes to food labels, the choice almost always boils down to two main players: direct thermal and thermal transfer.

Each of these technologies has a unique way of putting an image onto a label, and each comes with its own set of pros and cons, making them better suited for different food production environments.

If you have ever looked closely at a cash register receipt, you have seen direct thermal printing in action. It’s a beautifully simple process. The printer uses a heated printhead that makes direct contact with a special, heat-sensitive label material. This material turns black in the spots where heat is applied, creating your text and images. The best part? No ink, no toner, and no ribbons.

This straightforward approach makes direct thermal printers a fantastic choice for items that have a short shelf-life.

The main trade-off here is durability. These labels are sensitive to heat and light, so they can fade over time or if they are exposed to sunlight or friction. This makes them a poor choice for any product that needs long-term identification.

Thermal transfer printing takes a completely different route. Instead of heating the label itself, the printhead heats a wax or resin ribbon. This ribbon then melts onto the label’s surface, transferring the ink and creating a far more durable and long-lasting image. The result is a print that can stand up to some seriously tough conditions.

This resilience makes it the go-to technology for products that need to survive a challenging journey from production to the customer’s home. It is the ideal choice for labels on frozen foods, items exposed to moisture, or products that will be handled constantly during transport and stocking. The final print is sharp, crystal clear, and highly resistant to smudging, chemicals, and abrasion.

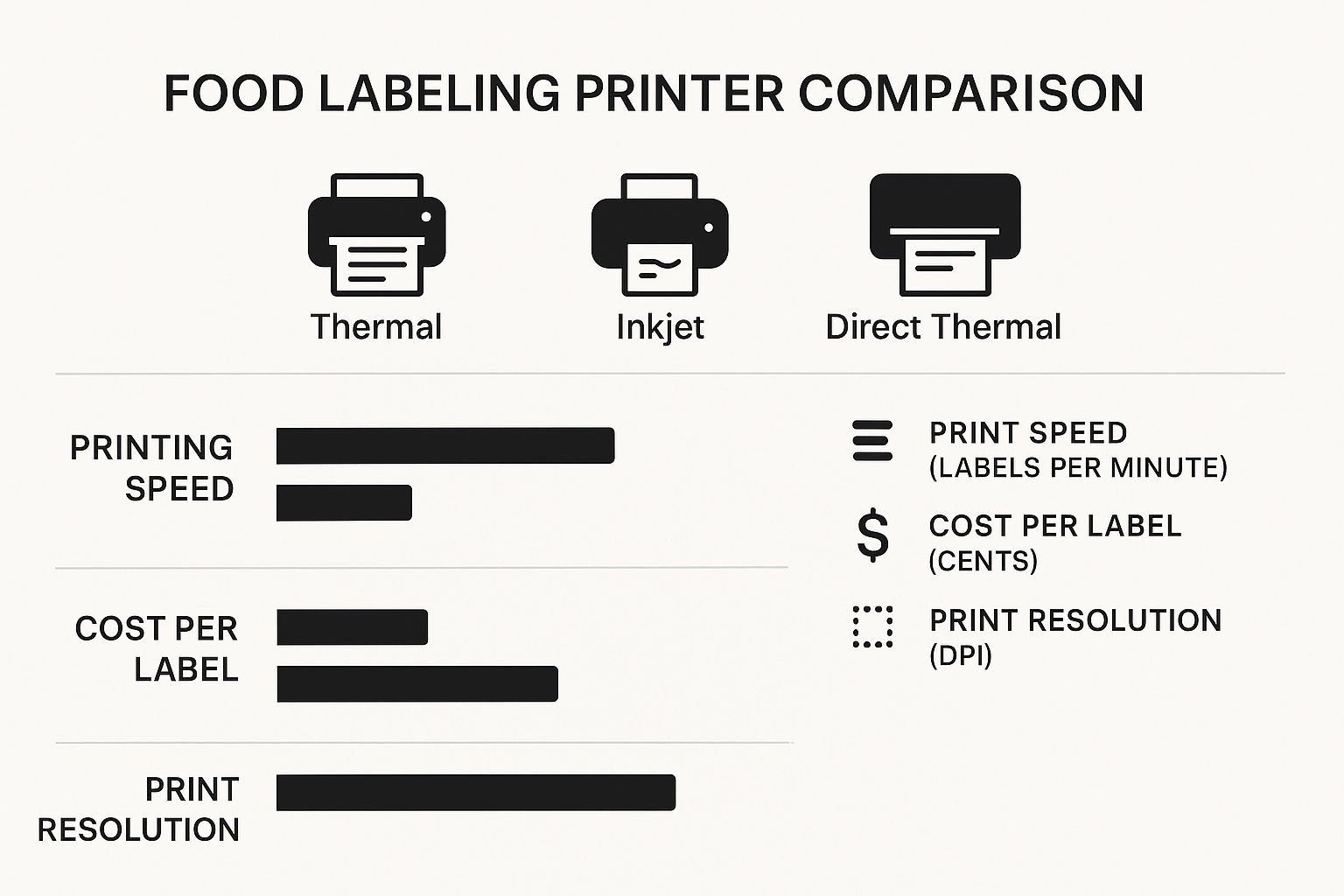

The image below gives a great visual comparison of how different printing technologies stack up against each other.

As you can see, thermal technologies often hit that sweet spot between speed and cost, which is why they are such a popular choice for so many food businesses.

To make the choice clearer, let’s break down the key differences between these two workhorse technologies.

| Feature | Direct Thermal | Thermal Transfer |

|---|---|---|

| Printing Method | Uses a heated printhead on heat-sensitive paper. | Uses a heated printhead to melt a ribbon onto the label. |

| Supplies Needed | Labels only. | Labels and ribbons. |

| Upfront Cost | Generally lower. | Generally higher. |

| Ongoing Cost | Lower cost per label (no ribbon). | Higher cost per label (ribbons needed). |

| Durability | Lower. Fades with heat, light, and friction. | Higher. Resistant to smudging, chemicals, and abrasion. |

| Best For | Short-life items (e.g., deli food, shipping labels). | Long-life products (e.g., frozen goods, assets). |

Thermal transfer is your best bet for longevity and resilience, while direct thermal is the champion of low-cost, short-term labelling.

While thermal printers really own the black-and-white label market, sometimes you need a splash of colour. This is where inkjet and laser printers come into play, especially for creating eye-catching retail packaging. Inkjet printers are brilliant at producing high-resolution, photo-quality labels that can make a premium product pop on the shelf. You’ll often see them used for small-batch artisanal goods like jams, craft beers, or gourmet sauces where visual appeal is everything.

Laser printers are less common for on-demand, roll-fed food labelling. They can be used for printing sheets of labels and offer sharp text and good durability, but they are generally better suited for office work than the fast-paced environment of a production line.

The growing demand for customised labels in the UK has pushed technological innovation in the printer market. With consumers wanting more detailed product information, the choice of printer technology has become even more significant for food producers. Thermal printing technology holds over 45% of the market share for label printers, favoured for its cost-effectiveness and high-resolution output suitable for barcodes, expiry dates, and nutrition facts. Read the full research about the global label printer market for more details.

The best printing technology for your business depends entirely on your product’s journey. By matching the printer’s strengths to your operational needs- whether it’s for a short-life deli item or a frozen product that needs to last- you can produce consistently clear, compliant, and reliable labels every single time.

Knowing whether you need a direct thermal or thermal transfer printer is a great start, but it’s the specific features that will determine if your new machine becomes a trusted workhorse or a source of daily frustration. You have got to look past the core technology to find a printer that genuinely fits your business operations. These details are what make or break its performance in your unique environment.

Think of it like buying a van for your delivery business. You know you need a van, but you still have to decide on engine size, cargo capacity, and whether you need built-in sat-nav. The same logic applies here; the specs are what make the printer right for your workflow.

Print resolution is all about sharpness, and it’s measured in dots per inch (DPI). The higher the DPI, the crisper and more detailed your labels will be. For food labelling, this is not just about looking good- it’s a fundamental requirement for compliance and functionality.

A standard 203 DPI printer will get the job done for basic text and large barcodes, like the ones you see on outer shipping boxes. Step up to 300 DPI, and you’ll see a real difference in quality. This is often the sweet spot for producing sharp, readable ingredient lists and reliable barcodes. For tiny labels, perhaps on gourmet oil vials or spice jars where every millimetre counts, a 600 DPI printer might be necessary to fit all the required information legibly.

A barcode that won’t scan at the checkout or in the warehouse is more than an annoyance; it causes delays and erodes traceability. A higher DPI drastically reduces scan errors, keeping your whole operation running smoothly.

Print speed tells you how quickly a printer can churn out labels, measured in inches per second (IPS). For a small artisan bakery printing a few dozen labels a day, a modest speed of 4 to 6 IPS is perfectly fine. It gets the job done without creating a bottleneck.

But if you’re running a high-volume production line that packages hundreds of products an hour, you need a machine that can keep up. Industrial food labelling printers can hit speeds of 14 IPS or more. This kind of rapid output is needed to stop the labelling station from slowing down the entire packaging process.

How a printer talks to your other systems is a crucial, often-overlooked detail. The right connectivity options allow for a smooth, headache-free integration, whether you are printing from a single PC or a cloud-based inventory platform.

Here are the most common choices:

The UK’s barcode printer market, which is a huge support for the food industry, is expected to grow to around USD 750 million by 2035. This boom is being driven by the demands of e-commerce and logistics, where smart, connected devices are non-negotiable. Features like cloud integration are fast becoming standard as businesses seek more versatile and compliant food labelling solutions.

A printer is only as effective as the labels it can handle. Media compatibility simply means the range of label sizes, materials, and adhesives the printer can work with. Before you commit, always check the spec sheet for its maximum print width and the types of label stock it supports. For more information on this, have a look at our guide on the best food label printer options.

Finally, don’t forget the printer’s build quality. A desktop model with a plastic casing is fine for a clean, low-volume setting like a café counter. But a busy factory floor- with its dust, moisture, and temperature swings- calls for a rugged industrial printer with a sturdy metal frame to protect its sensitive internal components.

Staying on the right side of UK food labelling laws is not just a box-ticking exercise; it’s fundamental for any food business. Get it right, and you protect both your customers and your reputation. Get it wrong, and you could be facing expensive recalls or even legal trouble. This is where a good food labelling printer proves its worth, producing the crisp, clear text required to meet every single standard.

The food industry is always shifting. The UK label printer market is fiercely competitive, driven by the constant need to comply with regulations and meet consumer demand for more transparency. Brexit has also introduced new supply chain hurdles, forcing producers to find more flexible ways of working. You can dig deeper into these market trends in the report on the UK label printer market.

For almost all pre-packaged foods sold in the UK, there’s a core set of details you absolutely have to include. This information is the bedrock of a compliant label, giving people what they need to make safe, informed choices.

Your label must clearly show:

A compliant label is more than just a list of ingredients. It’s a promise of transparency. The quality of your printed information says a lot about the integrity of your product and your brand.

Natasha’s Law was a major step forward for UK food safety. It targets food that is pre-packaged for direct sale (PPDS)– that is, food that’s packed on the same site where it’s sold to customers, before they order it.

Think of items like:

Under Natasha’s Law, these items must now have a label with a full ingredients list, with all allergenic ingredients clearly marked. This law closed a loophole where this information could previously be given verbally by staff. Having a dependable printer on-site is needed for creating these detailed labels as and when you need them.

Date marks are a critical part of food safety and communicating quality. It is key to know the difference and use the right one for your product.

You also need to state the country of origin if leaving it out could mislead a customer. For certain foods, like some fresh meats and honey, this information is mandatory anyway. Other details like nutritional information, the net quantity, and storage instructions are also usually required, making sure customers have everything they need to know.

All of this has to be printed clearly and be durable enough to last- a job that calls for specialised equipment. To learn more about the hardware that handles this, take a look at our guide on food labelling machinery.

It’s one thing to talk about specs and features, but it’s another to see how these printers actually solve real-world problems on the production floor. The best printer is not necessarily the most expensive or fastest one; it’s the one that fits your specific operation like a glove.

Take a small, independent bakery, for example. Every day, they’re creating fresh cakes, sandwiches, and pastries that all need clear date labels and ingredient lists. A compact desktop printer is perfect for this. It takes up hardly any counter space and lets staff print small batches of labels on the fly, making sure every item is properly marked for freshness and safety before it goes out the door.

Now, let’s switch gears and imagine a massive meat processing plant. The environment is cold, damp, and the production line moves at a relentless pace. In this scenario, only a rugged industrial printer will do. These machines are built like tanks, with tough metal casings that can handle harsh conditions and churn out thousands of labels a day without breaking a sweat.

Here, the main job is often printing durable traceability barcodes onto synthetic labels. These are not your average paper stickers; they have to survive freezing temperatures and constant handling. This allows every single product to be tracked from the plant all the way to the supermarket shelf- a key process for quality control and for acting swiftly if a product recall is ever needed.

The right food labelling printer becomes an invisible yet critical part of the production process. For high-volume operations, it’s not just about printing a label; it’s about maintaining the flow of the entire line without creating a bottleneck.

Meal-prep delivery services are another kettle of fish entirely. They deal with a huge number of customised orders, and each one needs a unique label with the customer’s details, dietary notes, and specific heating instructions. Accuracy and speed are everything.

This is where automation comes in. Many of these services link their food labelling printers directly to their ordering software. As soon as an order is placed, the system automatically generates the right label. It is then printed and applied to the correct meal container. This process gets rid of manual data entry, dramatically cutting down the risk of human error and making sure the right customer gets the right meal every time.

To get a sense of how these printers work alongside other equipment, our guide to food labelling machinery gives you a bird’s-eye view of the entire production setup.

The right printer really depends on the daily grind of the business. The table below breaks down some common scenarios to show how different operations can find their perfect match.

| Business Type | Recommended Printer Type | Features Needed |

|---|---|---|

| Local Bakery/Café | Desktop Direct Thermal | Compact size, low print volume capability, easy media loading. |

| Meat Processing Plant | Industrial Thermal Transfer | Rugged metal construction, high print speed, chemical resistance. |

| Meal-Prep Service | Desktop/Industrial | Network connectivity (Wi-Fi/Ethernet), software integration. |

| Artisan Sauce Maker | Colour Inkjet Printer | High-resolution printing for branding on retail products. |

As you can see, from a small café needing simple date labels to a large factory requiring complex tracking barcodes, there’s a printing solution designed for the job. Matching the technology to the task is the key to an efficient and compliant food labelling process.

Stepping into the world of food labelling printers can feel a bit overwhelming. It’s not just about the tech; it’s about finding what works for your daily grind. Let’s tackle some of the most common questions that pop up, so you can feel confident you are making the right call.

Getting these basics right is key to matching a printer and its supplies to your products and your kitchen or factory floor.

This is a big one. For anything you are keeping chilled or frozen, standard paper labels just will not cut it. The moment they hit a cold, damp environment, they start to soak up moisture. The print smudges, and the label itself can weaken, bubble up, or just fall right off.

Your best bet is to go for synthetic materials like polypropylene or polyester. These are tough, water-resistant plastics that keep the label looking sharp and staying put for the long haul.

But the material is only half the story. You also need a permanent, freezer-grade adhesive that’s designed to grip tightly in the cold. It’s what stops the label from peeling off in the freezer. And a final tip: always double-check that the labels you’re buying are compatible with your specific printer, whether it’s direct thermal or thermal transfer.

Yes. Most food labelling printers ship with some basic design software, which is perfect for getting started. You can easily create simple, clean labels with text, barcodes, and best-before dates.

If you want to get a bit more creative, these printers usually play nicely with third-party design programmes. You simply design the label on your computer and send it to print, just as you would with a regular office document. The main thing is to check your printer’s software compatibility.

Most models come with drivers for standard operating systems like Windows or macOS. This means you can print directly from lots of different applications, giving you loads of flexibility. Just make sure your design template is set to the exact size of your label roll to prevent any wonky prints.

This freedom lets you keep your branding consistent and hit all your regulatory marks without needing to be a design whizz. You can even set up templates for different products and pull them up whenever you need them, which is a real time-saver.

The sticker price is just the beginning. To really understand the cost, you have to look at the whole picture- what you’ll spend on supplies and potential upkeep over the life of the machine.

Your biggest ongoing cost will almost certainly be the labels themselves. The price tag on those can vary a lot depending on the material, size, and type of adhesive. As you would expect, tough synthetic labels for freezers will cost you more than basic paper ones.

If you’ve opted for a thermal transfer printer, you will also need to budget for thermal ribbons. The good news is one ribbon can print quite a few rolls of labels, but it is still an extra cost to factor in. The other thing to keep in mind is the printhead; it’s a wearable part that will eventually need replacing. When you add up the cost of labels, ribbons (if you need them), and any potential repairs, you get a much more realistic idea of the total cost of ownership.

The main differences really boil down to their build quality, how much they can print, and their price. They are simply built for completely different jobs and environments.

For a manufacturing plant, a large-scale commercial kitchen, or a busy distribution centre, an industrial printer is the only way to go. Its sturdy construction means it can handle tougher conditions, like dust or changes in temperature, without missing a beat.

Yes, and thankfully, more sustainable options are hitting the market all the time. There has been a lot of concern around chemicals like BPA and BPS, which used to be common in thermal paper. That pressure has pushed manufacturers to come up with safer, phenol-free alternatives.

Today, many businesses are looking for labels that are not only free from these chemicals but are also kinder to the planet. Some of the best options include:

Choosing these kinds of options can really help support your business’s sustainability goals and shows your customers you’re making responsible choices.

Finding the right hardware is the first step toward a flawless labelling process. At Sessions UK, we provide a full range of manual, semi-automatic, and fully automatic labelling machinery to support businesses of all sizes. Explore our labelling machines to find the perfect solution for your production line.

Copyright © 2025 Sessions Label Solutions Ltd.