Think of a modern label machine for bottles as more than just a piece of kit that sticks on labels. It is the engine room for your branding, your compliance department, and a cornerstone of your production line’s efficiency. These systems are what guarantee every single bottle gets a perfectly placed, professional-looking label – that final, critical handshake between your brand and your customer.

Whether you’re running a small craft brewery or a massive beverage plant, that little piece of paper or plastic is the first thing a potential buyer sees. It tells your brand’s story, carries product information, and must tick all the right regulatory boxes. Trying to do this by hand? It’s slow, inconsistent, and a recipe for costly mistakes like wrinkles, bubbles, or wonky placement.

This is where an automated or semi-automated label machine for bottles completely changes the situation. It turns a fiddly, labour-intensive job into a slick, repeatable process, giving you a flawless finish that truly reflects the quality of what’s inside the bottle. For any business serious about growing, making this switch is fundamental.

Imagine the label is your product’s suit of armour. A crisp, perfectly applied label screams professionalism and an eye for detail. On the flip side, a peeling or crooked one can make even a premium product look cheap, damaging customer trust before they’ve even twisted the cap.

Consistency is everything. When every bottle on the shelf is a perfect mirror of the next, it builds a powerful and trustworthy brand image. That’s a level of uniformity that’s next to impossible to get right by hand, especially when you’re dealing with large volumes.

It’s not just about looking good. A dedicated labelling machine dramatically ramps up your output. While someone labelling by hand might get through a few hundred bottles an hour on a good day, an automatic system can effortlessly handle thousands with pinpoint accuracy. This surge in productivity helps you meet growing demand, trim labour costs, and get your products out the door faster.

A well-chosen labelling machine isn’t just another expense; it’s an investment in your brand’s consistency and your company’s growth. It guarantees every bottle that leaves your facility is a perfect ambassador for your brand, all while saving you time and money.

The UK market has its own set of challenges, with sustainability sitting right at the top of the list. Here, the demand for bottle labelling machines is heavily influenced by strict environmental regulations and a strong consumer preference for eco-friendly packaging. Policies like the UK’s Plastic Packaging Tax are pushing businesses to embrace recycled plastics, glass, and aluminium. For a deeper look into the machinery we offer, you can explore our comprehensive guide on label machines for bottles at https://sessionsuk.com/label-machines-for-bottles/.

This green shift directly impacts the kind of machinery needed. Today’s labellers have to be sophisticated enough to handle thinner, more sustainable materials without sacrificing an ounce of performance. Market analysis suggests the UK bottles market is set to grow at a compound annual rate of about 4.6% between 2025 and 2035, largely fuelled by these green initiatives. Getting to grips with these trends is key for choosing a machine that not only works for you today but also sets you up for the future.

Choosing the right labeller for your bottles comes down to understanding the core technologies on offer. Each type works differently, bringing its own set of advantages depending on your product, how many bottles you’re running, and the final look you’re after. Think of it like picking the right tool for a job-you wouldn’t use a sledgehammer to hang a picture frame.

You’ll generally come across three main categories: pressure-sensitive, wet glue, and shrink sleeve systems. The way each one applies a label is fundamentally different, which has a knock-on effect on everything from the materials you can use to the speed of your production line. Let’s look into how each one works and where they really shine.

Pressure-sensitive labellers are probably the most common type of bottle labelling machine you’ll see today, especially for small to medium-sized businesses. The concept is beautifully simple: they apply pre-glued labels (often called self-adhesive labels) from a roll onto the bottle. A little bit of pressure is all it takes to create a solid bond.

This method is incredibly flexible. It can handle a huge range of label materials, from standard paper to fancy clear films, and works a treat on glass, plastic, and metal surfaces. The setup is also generally less fiddly than other systems, making them a fantastic choice if you’re frequently switching between different products.

Wet glue labellers use a more traditional approach. Instead of using labels that are already sticky, these machines apply a cold glue to a stack of cut paper labels just moments before application. A pallet snatches a single label, the glue is rolled onto its back, and it’s then pressed onto the passing bottle.

This system is in its element in high-volume production lines where speed and low consumable costs are king. Paper labels are often cheaper than their self-adhesive cousins, and when you’re labelling thousands of bottles an hour, those savings quickly add up. They’re a firm favourite for big-name beverage companies for this very reason.

The main trade-off with wet glue systems is their complexity. They demand more setup time, need diligent cleaning to stop glue from building up, and are really best suited for long, consistent runs of the exact same product.

For instance, a major soft drink manufacturer would almost certainly use a high-speed rotary wet glue labeller. This kind of machine can apply front, back, and neck labels to thousands of glass bottles every hour with pinpoint precision, keeping running costs down while meeting massive consumer demand.

Shrink sleeve applicators take a completely different tack. Instead of a simple sticker, these machines slide a plastic sleeve over the entire bottle. The bottle then travels through a heat tunnel, which makes the sleeve shrink and mould itself perfectly to the container’s unique shape.

This technique gives you 360-degree branding coverage, turning the whole bottle surface into a canvas for your graphics and information. It’s also brilliant for creating tamper-evident packaging, as the sleeve can be designed to cover the cap. Shrink sleeves are the go-to for unusually shaped or contoured bottles where a normal label would just wrinkle or fail to stick properly. Think of a sports drink with a curved, ergonomic bottle-it needs that vivid, full-body branding to grab attention on the shelf.

To help you weigh up the options, the table below breaks down the key differences between these three technologies.

| Feature | Pressure-Sensitive (Self-Adhesive) | Wet Glue Labeller | Shrink Sleeve Applicator |

|---|---|---|---|

| Label Material | Paper, film, foil, synthetics | Primarily paper | PET-G, OPS, PVC, PLA films |

| Adhesive | Pre-applied on label roll | Cold or hot melt glue applied during labelling | None (heat shrunk onto container) |

| Best Production Scale | Low to high volume | High to very high volume | Low to high volume |

| Cost Per Label | Medium to high | Low | High |

| Changeover Speed | Fast | Slow | Medium |

| Ideal Container Shape | Flat, round, oval, slightly tapered | Round, square, flask-shaped | Any shape, including complex contours |

| Branding Area | Partial coverage (front, back, neck) | Partial coverage | Full-body, 360-degree coverage |

| Key Advantage | Flexibility and ease of use | Lowest consumable cost at high speeds | Maximum design impact and tamper-evidence |

Each machine has its place, and the best choice depends on balancing your budget, production volume, and what you want your final product to look like on the shelf.

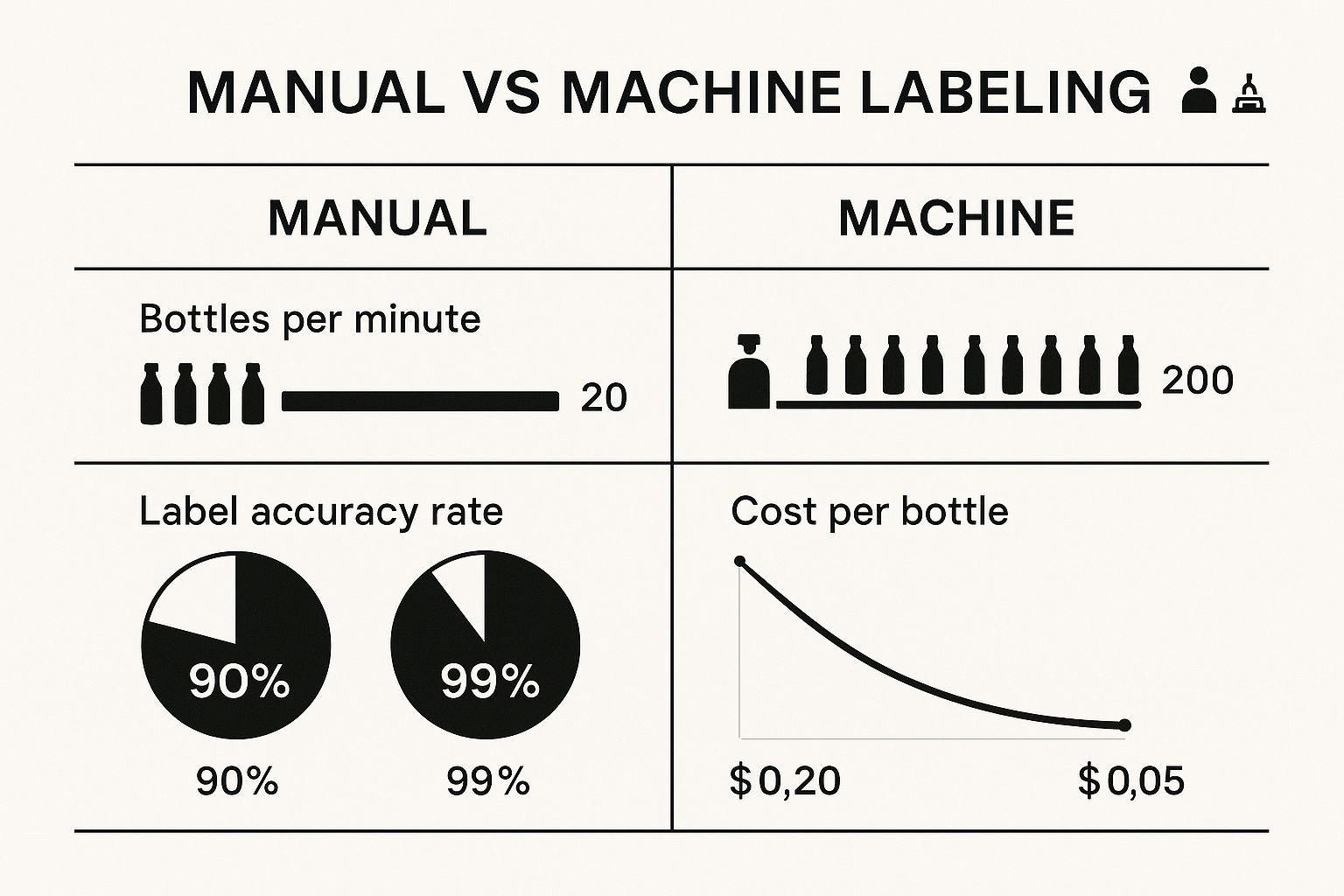

The image below gives a stark comparison of the efficiency gains when you move from labelling by hand to using a machine.

The data speaks for itself. A labelling machine can deliver a tenfold increase in speed, a massive jump in accuracy, and a remarkable 75% reduction in the cost per bottle. It’s a major improvement for any growing business.

So, you’ve got a handle on the main types of label applicators. What’s next? It’s time to look into the specific features that separate a good label machine for bottles from a truly great one.

Think of it like putting together a spec sheet before you buy a new car. You need to be crystal clear on what’s non-negotiable for your day-to-day operations and what’s just a ‘nice to have’. Choosing a machine based on its actual capabilities, not just its price tag, is a decision that will pay you back for years to come.

It all boils down to performance metrics like speed, accuracy, and versatility. These are the foundations of an efficient production line, directly shaping your output, the quality of your finished product, and your ability to pivot when you launch something new.

The real engine of any labelling machine is its ability to perform consistently, day in and day out. Before you even think about talking to a supplier, you need a firm grasp of your own production requirements. This simple step will help you immediately filter out machines that just aren’t up to the job.

Pay close attention to these three areas:

It sounds obvious, but your machine must be able to handle your specific bottles and labels without any fuss. Not all systems are built the same in this respect. A machine designed to label standard glass wine bottles might really struggle with lightweight PET plastic or a uniquely shaped craft spirit bottle.

A machine’s true value is directly tied to its adaptability. The ideal system won’t just handle what you’re producing today; it will give you the flexibility to work with new materials and shapes as your product line grows.

When you draw up your checklist, make a list of the full range of materials you use or plan to introduce. This should cover:

Modern bottle labellers are run by sophisticated electronics that make operation and setup much simpler than they used to be. The user interface is where your team will interact with the machine every day, so it absolutely has to be intuitive.

A Programmable Logic Controller (PLC) is the brain behind most automated systems, controlling all the mechanical movements with incredible precision. This is typically paired with a touch-screen Human-Machine Interface (HMI). A clear, responsive HMI means operators can easily tweak settings, load up new jobs, and troubleshoot problems without needing a degree in computer science.

Looking beyond the core functions, there are several optional features that can add huge value to your operation. These add-ons can boost your quality control, help with regulatory compliance, and broaden what the machine is capable of.

Things are moving quickly in this field. We’re seeing more businesses adopt smart labels with NFC or RFID technology for better product tracking. With the sustainable labels market forecast to hit around $18 billion globally by 2025, UK manufacturers are also under pressure to use eco-friendly materials that comply with waste regulations. This makes choosing a forward-thinking machine more important than ever.

A label machine for bottles is never a one-size-fits-all solution. The design, speed, and features of any given machine are directly shaped by the unique pressures and priorities of the industry it serves.

From the sterile, high-stakes environment of a pharmaceutical plant to the sheer speed of a soft drink bottling line, the right machine makes all the difference. Understanding what each sector needs shows you why certain features are non-negotiable for some, while being completely irrelevant for others.

In the pharmaceutical world, there is absolutely no room for error. A single mislabelled medicine bottle or vial can have devastating outcomes, so accuracy and traceability aren’t just important-they’re everything. The machines built for this job are engineered for precision above all else.

You’ll find these labellers often come with advanced verification systems built right in. Integrated cameras and scanners meticulously check every single label for the correct barcodes, lot numbers, and expiry dates. If even the slightest detail is off or unreadable, that bottle is instantly kicked off the line. It’s a critical safety net.

Nowhere is the demand for speed more intense than in the fast-moving consumer goods (FMCG) industry. Production lines churning out sauces, juices, or spirits are relentless, often labelling thousands of bottles every hour. The machinery simply has to keep up, day in and day out.

But it’s not just about speed. Durability is a huge factor. These environments are often wet and messy from spills and condensation, so equipment is almost always built from stainless steel to fend off rust. These machines also have to endure tough daily cleaning routines to meet strict hygiene standards.

Case Study: A Craft Brewery’s Growth

A local craft brewery was struggling to keep up with demand. Hand-labelling was inconsistent and slow, creating a major bottleneck. By bringing in an automatic wrap-around labeller, they boosted their bottling speed by a massive 400%. This simple upgrade allowed them to finally supply larger retailers and give their brand a professional, consistent look on crowded shelves.

This is a story we see all the time. Making the jump from manual to automated labelling is a big step for growing businesses. The efficiency gained from a reliable label machine for bottles is what fuels expansion. For a deeper look into these benefits, you can explore our article: https://sessionsuk.com/label-printing-machine-for-bottles-exploring-the-efficiency/.

For cosmetics, it’s all about visual appeal. The label is a massive part of the product’s luxurious feel, which means its application has to be perfect. No wrinkles, no bubbles, no excuses. Many high-end brands opt for clear film labels to create a sleek ‘no-label’ look, which brings its own set of challenges.

Getting these clear labels on perfectly without trapping air bubbles or leaving smudges requires very specific technology. These machines often use clever roller systems or precisely targeted air jets to press the label on with flawless, invisible results.

On top of that, cosmetic containers are famously varied. One minute you’re labelling a tall, thin tube, and the next it’s an odd-shaped jar. A machine in this sector has to be incredibly adaptable, with quick-change parts to handle different product runs without grinding production to a halt.

As you can see, every industry puts its own unique spin on the labelling process. A machine’s features are never chosen by chance; they are a direct response to its working environment and what the final product needs to succeed.

Picking the right label machine for bottles isn’t just a purchase; it’s a strategic move that directly impacts your production speed and how your brand looks on the shelf. The best place to start isn’t by browsing machine catalogues, but by taking a hard look at your own operation. A proper, honest assessment of your current needs-and where you want to be in a few years-is your roadmap to finding the perfect fit.

This means getting specific with your production volume. How many bottles are you labelling per hour right now? What are your growth targets? It’s a classic mistake to buy a machine that only meets today’s demand, as it can quickly become a bottleneck that holds your business back.

Before you even think about talking to suppliers, you need to create a detailed profile of your products. This information is the key to finding a machine that works seamlessly with your setup. Get this wrong, and you could be facing constant jams, wonky labels, and costly downtime.

Start by getting the specifics down on paper:

Don’t forget to think about what’s next for your product line. A machine that allows for quick, tool-free changeovers gives you the agility to add new bottle sizes without causing a major production headache. For a deeper look, our guide offers more practical advice on how to choose the best bottle labelling machines for your specific line.

The price tag on a labelling machine is just the beginning of the story. To get a true sense of the investment, you need to think in terms of Total Cost of Ownership (TCO). It’s a much more realistic way to look at the numbers and avoid nasty financial surprises down the road.

TCO factors in all the ongoing costs that add up over the machine’s lifetime. Think about routine maintenance, the cost of spare parts like rollers and belts, and the time and money spent training your team. A cheaper machine that’s constantly breaking down can end up costing you far more in lost production than a more reliable, higher-priced model ever would.

A well-chosen label machine for bottles pays for itself through efficiency, reliability, and the professional finish it gives your product. Focusing only on the initial cost can lead to a system that cannot keep up with your business’s growth.

The UK’s plastic bottle market is projected to hit USD 648.27 million by 2030, and a major trend is “lightweighting”-using thinner, lighter plastics. This means modern labellers need to be precise enough to handle more delicate materials. It’s a perfect example of why choosing adaptable, forward-thinking equipment is so important.

Once you have a clear spec sheet, you can start looking at suppliers. The right partner does a lot more than just sell you a piece of kit; they provide the support that keeps your line running without a hitch. This is especially true when you’re sourcing machinery here in the UK.

Always look for a supplier that offers local technical support. Having an expert who can get to your site quickly when something goes wrong is absolutely invaluable. You should also insist on a demonstration using your actual bottles and labels. It’s the only real way to see if the machine can handle your specific products without any trouble.

Finally, do your homework. Check customer reviews and ask for references to get a feel for their reputation. A good investment is one you feel confident about, and that comes from knowing you’ve got a dependable partner in your corner.

As you get closer to choosing a labelling machine for your bottles, a few common questions always seem to pop up. Getting straight answers is the key to feeling confident in your decision and making sure it lines up with your production goals. We’ve put together some of the most frequent queries we hear to help you out.

Think of this as a way to clear up any confusion and offer some practical insights into what it’s like to work with these systems day-to-day. Understanding these details will help you pick a machine that not only works for you now but can also grow with your business.

It all boils down to how much hands-on work is needed. With a semi-automatic machine, an operator has to physically place each bottle onto the machine to get its label. This makes them a fantastic choice for small batches, start-ups, or anyone producing a wide variety of products in smaller quantities.

A fully automatic machine, on the other hand, is built right into a production line with a moving conveyor. Bottles are fed, labelled, and sent on their way without anyone needing to touch them. This kind of setup is designed for medium-to-high volume operations where speed and consistency are everything.

Yes, for the most part. Modern labellers are built to be flexible. They can usually handle a decent range of bottle heights, diameters, and shapes-from standard rounds to ovals or even squares. This versatility usually comes from using specific ‘change parts’ or making simple mechanical adjustments to guide the containers properly.

When you chat with a supplier, it’s a great idea to have all your different bottle types ready to show them. A key feature to ask about is how quick and easy it is to switch between bottle types. Look for machines that offer tool-free changeovers, as this will save you a massive amount of downtime between production runs.

Getting that perfect, straight label application is a team effort between the machine and the materials. The machine itself does most of the heavy lifting. Look for features like orientation sensors, which are brilliant for non-round containers, and robust handling systems that hold the bottle firmly in place so it can’t spin while the label is applied.

A high-quality, precise label dispenser is the heart of the machine. But don’t forget your labels-using well-made labels with consistent backing paper and a good quality adhesive makes a huge difference in getting that flawless finish on every bottle.

A little bit of routine care goes a long way in keeping your machine running smoothly and lasting for years. Typical tasks include a daily clean of the sensors and wiping away any sticky adhesive residue from the applicator. It’s also standard practice to regularly check moving parts like rollers and belts for any signs of wear and tear.

Your supplier should give you a proper maintenance schedule and offer training. We always recommend keeping a small stock of common wear parts, like peel plates and drive belts, on hand. It’s a simple step that can save you from a major headache and long shutdowns while you wait for a replacement part to arrive.

Ready to find the perfect labelling solution for your bottles? The expert team at Sessions UK is here to help you navigate the options and select a machine that fits your exact production needs.

Explore our full range of bottle labelling machines at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.