Choosing the right label machines for bottles is not about finding the most advanced or fastest model on the market. It is about being honest about your own production reality. The perfect labeller for a craft distillery putting out 500 bottles of gin a week is completely different from the one needed by a national soft drink brand churning out thousands every hour. It all comes down to matching the machine to your operation, not the other way around.

Before you start looking at spec sheets or talking to suppliers, you need to map out your own requirements. Getting this step right from the outset saves you from two costly mistakes: overspending on a machine with features you will never touch, or buying a system your business outgrows in just six months. A solid requirements document is your best friend in this process.

A big part of the early discussion is how you will pay for it. Take the time to properly explore the financial side of things by understanding the nuances of leasing vs buying equipment. This decision will have a direct impact on your cash flow and long-term costs.

The first number you must pin down is your required throughput. This is usually measured in bottles per minute (BPM) or bottles per hour (BPH), and it is the single biggest factor determining whether you need a manual, semi-automatic, or fully automatic machine.

Do not just pull a number out of thin air. Get forensic. Look at your sales forecasts, your production schedules, and your ambitions for growth.

One of the most common pitfalls is businesses buying a machine that just barely meets their current needs. Always plan for at least 25-50% growth in capacity over the next two to three years. That bit of forward-thinking protects your investment and prevents frustrating bottlenecks down the line.

Next, let’s talk about the physical products themselves. The size, shape, and material of your bottles and labels will dramatically narrow down your options. A machine that flawlessly labels standard cylindrical wine bottles might completely bungle a square gin bottle or a tapered cosmetic jar.

Before you pick up the phone to a supplier, get a detailed profile of your products.

Putting together a clear spec sheet for every single bottle and SKU in your lineup is time well spent. When you can present this information to a supplier, they can immediately point you towards the most suitable and versatile label machines for bottles, making the entire process far smoother and the final choice a perfect fit.

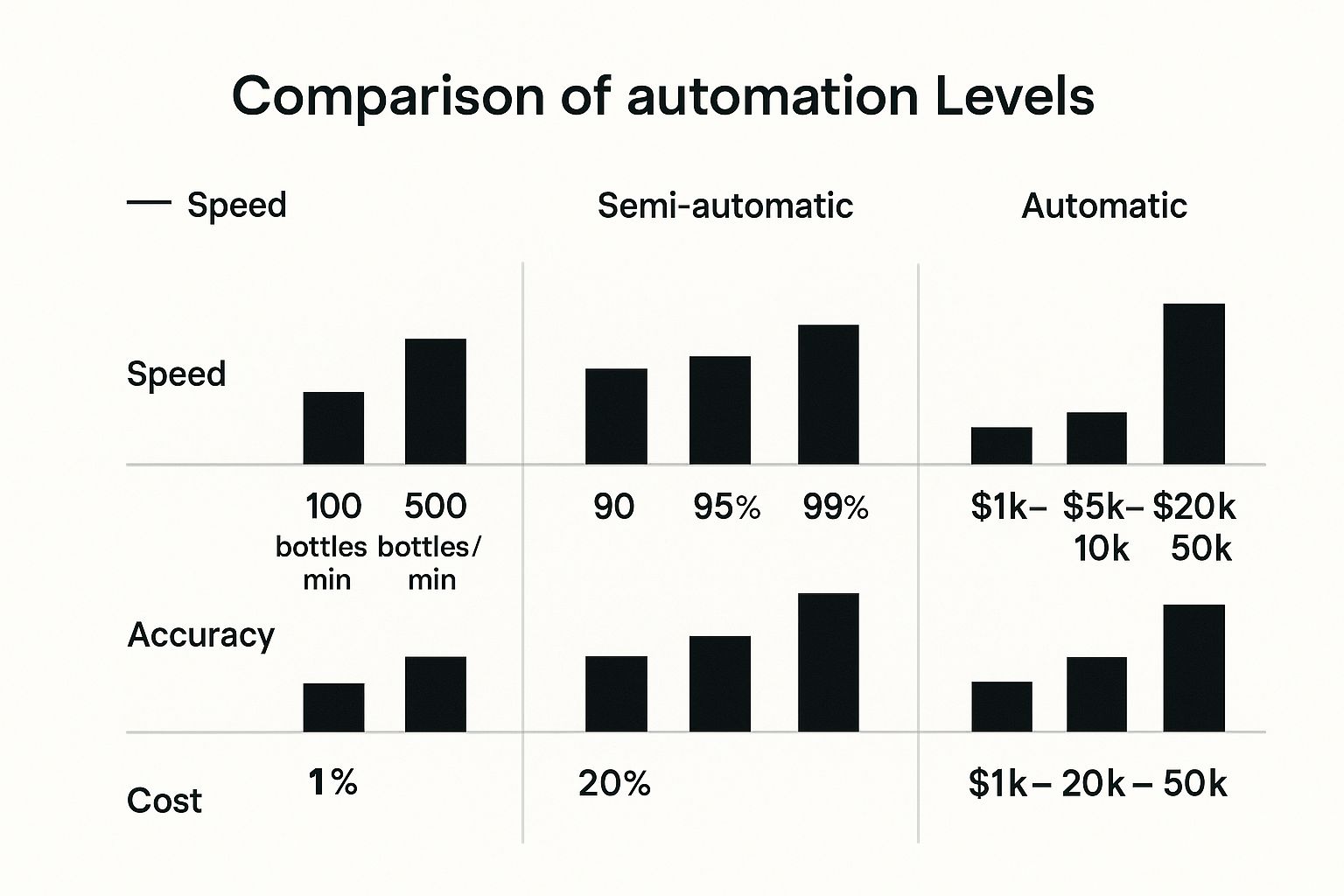

Choosing the right machine comes down to understanding the fundamental differences between what is out there. This decision will have a direct knock-on effect on your production speed, the accuracy of your labelling, and your initial investment. Broadly speaking, you are looking at three main categories: manual, semi-automatic, and fully automatic, and each one is built for a different scale of operation.

It helps to think about the trade-offs. As you move up the ladder in automation, you gain speed and precision, but the cost naturally increases too.

This drives home the point: you have got to match the machine’s capabilities to your actual production volume. There is no sense in buying a supercar for a trip to the local shops.

Let’s start with the basics. Manual labellers are as straightforward as they sound, often using a simple hand-crank or lever to apply labels one bottle at a time. They are a great starting point for micro-producers or for testing out new product concepts where a low upfront cost is more important than perfect consistency.

Semi-automatic machines are the perfect middle ground and a very popular choice for growing businesses. Here, an operator places a bottle into a jig, and the machine takes over, applying the label when triggered by a sensor or footswitch. You get a huge leap in speed and consistency over doing it by hand, which is why so many craft producers land here.

Then you have the top tier: fully automatic labellers. These are beasts of efficiency, designed to slot right into your production line. Bottles move along a conveyor, are automatically spaced and labelled, and then continue on for packing without a human hand touching them. For any high-volume operation, they are a necessity; relying on people at this stage would just create a massive bottleneck.

In the UK, the beverage sector is a great example of this, showing a strong shift towards automation. Around 27.45% of automatic labeller shipments are destined for beverage companies, with machines in the 61-200 BPM (bottles per minute) range being the most common.

Beyond how automated a machine is, you also need to think about how it applies the label. The technology you pick is entirely dependent on your label’s material, its design, and your container.

Here is a breakdown of the most common technologies you will come across in the UK market.

| Technology Type | Best For | Key Advantage | Consideration |

|---|---|---|---|

| Pressure-Sensitive | Most products, from craft gin to cosmetics | Versatile and clean, works with many materials | Label quality is key; requires pre-printed self-adhesive labels on a roll. |

| Wet-Glue | High-volume runs like beer and canned goods | Extremely cost-effective for paper labels | Can be messier; requires clean-up and glue maintenance. |

| Shrink-Sleeve | Uniquely shaped containers, full-body branding | Offers 360-degree, tamper-evident graphics | Requires a separate heat tunnel, which adds to the footprint and cost. |

| Roll-Fed | Mass-market beverages (e.g., soft drinks, water) | Incredible speed and low label cost per unit | Best for very high volumes; less flexible for small, varied batches. |

The right choice comes down to your specific product. A wrap-around machine for a cylindrical beer bottle is a totally different piece of kit than a front-and-back system needed for a flat-sided artisan gin bottle. The shape of your bottle dictates the mechanics of the machine.

To dig deeper into matching a machine to your product, have a look at our complete guide on how to choose the best bottle labelling machines for your production line.

A modern labeller does more than just stick labels on bottles; it should be a workhorse that makes your entire production process smoother. The real difference between a basic machine and a truly high-performance system is found in the features that solve common production headaches, from inconsistent application to lengthy changeover times. When you know what to look for, you are not just buying a piece of equipment-you are making a strategic investment.

I always tell clients to start by looking for features that reduce manual adjustments and the chance for human error. These are the small, smart details that deliver huge efficiency gains down the line.

Accuracy is everything. A wonky, creased, or misplaced label looks amateur, and that can seriously damage your brand’s reputation in a customer’s eyes. Top-tier label machines for bottles employ a clever mix of tech to nail the application every single time.

Modern labellers are all about consistency. I always recommend looking for systems with precise stepper motor controls. These motors guarantee the label roll moves the exact same distance for every single application-an absolute must for maintaining accuracy at high speeds.

Downtime is the silent killer of productivity. If you are running multiple products, the time it takes to switch from one bottle size or label to another can decimate your output. This is where features built for flexibility really prove their worth.

Tool-less changeover is a great feature and something I consider a necessity. It means your operators can adjust guide rails, applicator heads, and spacing wheels by hand using simple knobs or levers. No spanners, no Allen keys, no wasted time. A changeover that once took 30 minutes can be slashed to just five, which adds up to a massive saving over a production week. You can look deeper into the advantages of advanced bottle label applicators in our dedicated post.

For many industries-think food, beverage, or pharmaceuticals-the label is more than branding; it is a legal document. Modern labellers often integrate other key processes directly into the machine, which is a massive plus.

An integrated thermal transfer printer, for example, can print variable data like best-before dates, batch codes, or serial numbers onto the label moments before it is applied. If you need to meet strict regulatory standards, this is not a nice-to-have; it is a necessity.

Some machines go even further with inline camera inspection. A small camera scans each label post-application to verify that barcodes are readable and all the printed information is present and correct. This level of automation is becoming the standard in sectors like the UK beverage industry, where producers are constantly hunting for ways to improve efficiency and cut costs.

Getting your new label machine for bottles through the door is a big win, but the real work starts the moment it lands on your production floor. A smooth integration is what turns a smart purchase into a genuine asset, rather than a frustrating bottleneck. It all comes down to preparing your space and your people.

Do not let the delivery day be a scramble. The installation should be a well-orchestrated event. Before the machine even ships, you should have a detailed conversation with your supplier about site requirements. Double-check that your electrical connections match the required voltage and amperage, check you have allocated enough floor space (with room to work around it!), and confirm how it will link up with existing conveyors if you are integrating it into an automated line.

With the machine physically in place, your focus needs to pivot entirely to the operators who will run it day in and day out. This is where you will get your money’s worth. Solid training is the single biggest factor in achieving long-term performance; it is the difference between a machine that hums along reliably and one that causes a constant stream of tiny, frustrating delays.

When the supplier’s trainer is on-site, go beyond the basics. Do not just learn how to turn it on and off. You need to dig deeper.

Good training gives your team ownership of the equipment. An operator who truly understands how the machine works is far more likely to notice a slight change in sound or performance, catching a small issue before it escalates into a major breakdown. That is a direct impact on your uptime and output.

The supplier’s technician cannot stay forever. To keep things running smoothly long after they have left, you need to capture that expert knowledge and translate it into simple, in-house documentation. Many businesses skip this step, but it is invaluable for maintaining consistency.

The goal here is not to write a technical manual; it is to create clear, visual guides that anyone on the team can pick up and follow. If you are looking for a structured way to do this, referencing best practices for Standard Operating Procedures (SOPs) for manufacturing can give you a great starting point for creating documents that new hires can rely on.

Keep it practical and easy to digest.

Putting in this bit of effort up front builds a culture of competence around your new investment. When your team is confident and well-resourced, you will see fewer mistakes, less downtime, and a much quicker return on your investment. It is a core part of learning how to achieve maximum labelling machine efficiency right from the start.

A quality bottle-labelling machine is a serious asset, but protecting that investment goes beyond just using it correctly. The real secret to a machine that runs smoothly for years, rather than causing constant headaches, is proactive and regular maintenance. You do not need to be an engineer; it is all about building a simple, consistent care routine to keep your equipment performing at its best.

Think of it this way: small, regular checks are your best defence against minor issues spiralling into major breakdowns. This foresight saves you a fortune in emergency repairs and prevents costly production downtime.

A structured approach takes the guesswork out of maintenance and keeps your team on the same page. The easiest way to do this is by breaking down the necessary tasks into daily, weekly, and even monthly checks. It creates a simple rhythm that operators can slot into their workday without much fuss.

Daily Habits (Just 5-10 Minutes):

Weekly Checks (15-20 Minutes):

Here is a tip I always give my clients: keep a physical logbook right next to the machine. Operators can initial each check after they have done it. It is a simple system, but it creates a clear record of care and accountability that makes a massive difference.

No matter how meticulously you care for your label machines for bottles, some parts will eventually wear out. It is just a fact of life. Being prepared for this is what separates a minor inconvenience from a full-blown production halt. Waiting days for a critical component to arrive can bring your entire line to a standstill.

The smart move is to keep a small inventory of common wear parts on hand. Your supplier can give you a list of recommended spares, but it usually includes things like:

The global market for these machines shows how important they are. Valued at roughly USD 4.5 billion, the industry is projected to hit USD 7.8 billion by 2033. This growth is fuelled by sectors like beverage packaging that cannot function without this level of automation. This trend shows just how central these machines are to modern manufacturing.

One of the most common maintenance headaches is dealing with adhesive residue. Over time, tiny bits of glue transfer from the label backing onto the machine’s rollers and plates. As this gunk builds up, it can cause labels to stick where they should not, tear, or apply crookedly.

When you are cleaning off adhesive, always use a solvent recommended by the machine’s manufacturer. Using harsh chemicals is a fast way to damage rubber rollers or sensitive electronics. The best practice is to apply the solvent to a cloth-not directly onto the machine-and gently wipe the sticky spots.

Following these simple steps will add years to your equipment’s life and help you sidestep many common application errors. If you find yourself in a jam, you can learn more by resolving common bottle labelling issues with quick fixes.

When you are looking to invest in a piece of kit as important as a bottle labeller, it is only natural to have a few questions. Getting straight answers is the only way to make a decision you will be happy with for years to come. We get asked a lot about label machines for bottles, so we have put together some practical answers to the most common queries we hear.

Choosing the right machine is always a balancing act between cost, capability, and the realities of your own operation. Hopefully, these insights will clear things up.

You will find that the price of a bottle labeller varies quite a bit. For a small business or a start-up just moving away from hand-labelling, a simple, entry-level semi-automatic machine is a great starting point and can be had for a few thousand pounds. They are fantastic for getting consistency without a huge initial investment.

On the other end of the scale, a fully automatic, high-speed machine built for a demanding production line can run anywhere from £20,000 to well over £100,000. These high-spec systems often come with integrated date coders, camera inspection systems, and other advanced features. The real trick is to weigh that upfront cost against the long-term savings in labour and the boost in your output.

Many modern machines are designed with flexibility in mind. If your product line-up includes a variety of bottle shapes and sizes, you will want to look for models that advertise “tool-less changeover” parts. This means your operators can quickly adjust the machine for different bottle diameters or heights using simple hand-wheels and levers, which dramatically cuts down your changeover times.

If you are thinking of switching between fundamentally different types of labels-say, from standard pressure-sensitive to a shrink-sleeve-you will almost certainly need a different machine. It is key to talk through your entire product portfolio with a supplier to find a machine that has the versatility you need.

The key thing to remember is this: while many machines can handle size variations of the same bottle type, they are not chameleons. They cannot just switch between different labelling technologies. Always get confirmation on a machine’s changeover capabilities for your specific containers.

Getting perfectly straight labels, time after time, all comes down to proper setup and a bit of routine care. The first and most important step is calibrating the machine correctly for your specific bottle. Automatic labellers use guide rails and bottle-spacing wheels to make sure every single container is in the perfect position just before the label is dispensed.

Cleanliness is another factor you cannot ignore. Keeping the rollers and the peeler plate free from any sticky adhesive residue is a requirement for a smooth, trouble-free run. Do not underestimate the importance of using high-quality, evenly wound label rolls. This helps prevent feeding problems that are a common cause of skewed labels.

Even the best-built machines can throw you a curveball now and then, but most issues are surprisingly easy to fix once you know what to look for. Label creasing or bubbling is a classic problem. It is often caused by incorrect tension settings on the label web or running the machine at a speed that does not quite suit the bottle’s shape.

Misaligned labels are another common headache, which usually points to the bottle-handling components needing a quick recalibration or a sensor adjustment. You might also see the label web break during a run, which is typically down to poor-quality label stock or having the tension wound up too tight. A bit of good operator training and a consistent preventative maintenance schedule will head off nearly all of these problems.

At Sessions UK, we do more than just sell equipment. We provide genuine, expert advice to find the perfect labelling solution for your production line. Feel free to explore our complete range of labelling machines to see how we can help your business thrive.

Copyright © 2026 Sessions Label Solutions Ltd.