Picking the right label makers for jars comes down to the size and scale of your operation. If you’re running a small home-based business, a manual applicator is a brilliant, low-cost way to get started and achieve fantastic results. If your brand is growing, you’ll soon appreciate the speed and precision that a semi-automatic machine brings. For large-scale manufacturing, nothing but a fully automatic system will do the job efficiently.

To make this choice a little easier, we’ve put together a quick comparison table. Think of this as a starting point to see where your business fits in right now.

| Type | Best For | Speed (Labels/Hour) | Cost | Key Benefit |

|---|---|---|---|---|

| Manual | Home businesses, startups, artisanal producers | Up to 500 | £ | Extremely low initial cost |

| Semi-Automatic | Growing brands, small to medium businesses | 500 – 1,500 | ££ | Balances speed with affordability |

| Automatic | Large-scale manufacturing, high-volume production | 1,500+ | £££ | Maximum speed and efficiency |

Each type serves a distinct purpose. The key is to match the machine’s capabilities with your production demands and budget.

Choosing the right machine is a pivotal decision. It doesn’t just stick a label on a jar; it affects your product’s shelf appeal, your production line’s speed, and your bottom line. The market is full of options, but they generally fall into one of the three main categories we’ve just looked at.

A good way to think about it is like choosing a vehicle. A manual labeller is like a bicycle – it’s affordable, perfect for short runs (small batches), and relies on your own power. A semi-automatic machine is more like a moped; it gives you a boost of speed with less effort, perfect for when demand starts to pick up. A fully automatic system? That’s the lorry, built for industrial-scale work on a non-stop production motorway.

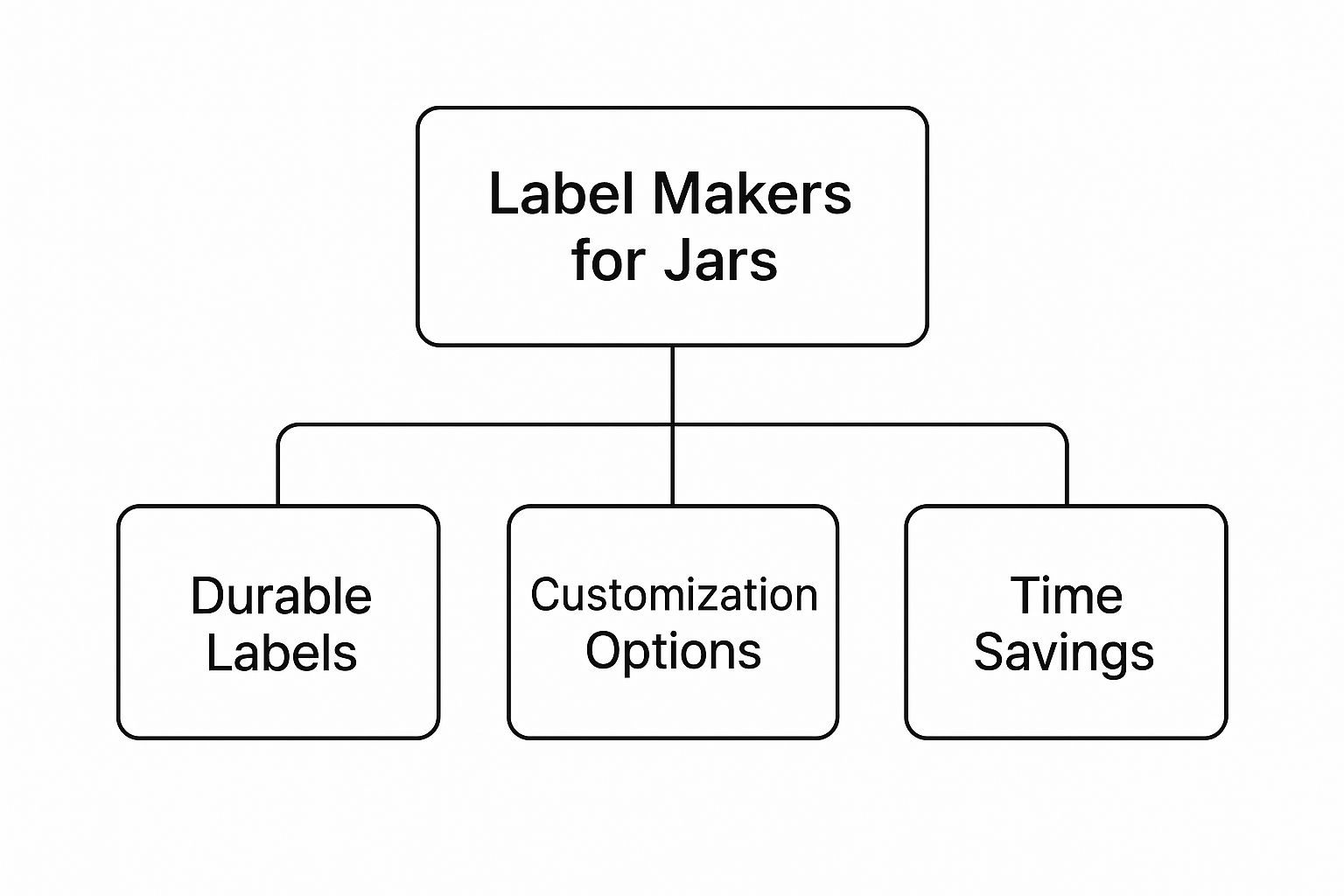

As the diagram shows, businesses aren’t just looking for any old labeller. They want equipment that is durable, can be customised to their needs, and saves them precious time.

Your decision needs to be a practical one, grounded in your current production volume, budget, and where you see your business heading in the future.

This need for better labelling is happening against a backdrop of market growth. In the UK, the jars market is set for solid expansion, with a projected compound annual growth rate of 3.6% through to 2035. This is largely driven by shoppers wanting high-quality packaging for their food and cosmetic products. By understanding exactly where your business stands, you can choose a machine that not only works for you today but also supports your growth for years to come.

When you’re starting out, choosing the right labelling machine for your jars often boils down to a classic balancing act: cost versus speed. It’s about figuring out where your business is right now and where you want it to go. The journey typically begins with manual applicators, which are a fantastic, low-cost starting point for any new or small-scale producer.

The best way to think of a manual labeller is like a heavy-duty tape dispenser, but one that’s cleverly designed for jars. The operator pops a jar into a cradle, turns a handle, and the machine rolls a pre-printed label smoothly onto the surface. It’s a simple mechanism, but it delivers results that are worlds away from the bubbles and crookedness of applying labels entirely by hand.

For businesses keeping a close eye on the budget or producing in smaller quantities, manual label makers are the perfect fit. Their main advantage is their simplicity; they require very little training to master and can be set up in minutes.

Of course, this method is only as fast as the person operating it. As your business starts to grow, the time spent turning that handle for every single jar can quickly become a major bottleneck, holding you back from taking on bigger orders.

The biggest limitation of a manual applicator is its speed. Even a skilled operator will struggle to get past 500 labels per hour. This makes them impractical for anyone hoping to supply larger retailers or manage a growing online demand.

When you hit that ceiling and manual labelling is just too slow, a semi-automatic labeller is the natural next step. These machines are the perfect middle ground, blending a bit of human involvement with the speed and precision of automation.

The process couldn’t be simpler: an operator places a jar onto the machine, taps a foot pedal or button, and the machine perfectly applies the label.

This is a huge leap forward in both speed and accuracy. The machine guarantees that every single label is applied in the exact same spot, giving your entire product line a consistent, high-quality finish. That uniformity is absolutely central for building a recognisable brand and meeting the tough presentation standards of retail stores. You can explore a range of semi-automatic labelling machines to see just how versatile they are.

Imagine a small honey producer who, after success at local markets, suddenly gets interest from a chain of local delis. To keep up, they’d need to upgrade. Moving from a manual machine to a semi-automatic one would be a major shift, allowing them to produce more jars, faster, all while making their product look sharp and professional on a crowded shelf.

For businesses that have truly scaled up, a fully automatic labelling system is the end-game for production efficiency. These aren’t just standalone machines; they’re designed to slot right into a fast-paced production line. Think of it as the most reliable and tireless member of your team, working away without needing constant supervision.

The entire process is fluid. Jars move along a conveyor belt, and the moment one passes a sensor, the labelling head is triggered. The machine applies the label with incredible precision, often using a wrap-around belt to smooth it on perfectly, getting a bubble-free finish before the jar continues its journey.

This level of automation is what’s fuelling major market growth. Valued at USD 9.3 billion, the global market for top labelling equipment is forecast to hit USD 19.8 billion by 2035. This shows a massive industry-wide shift towards faster, more reliable solutions, which you can read more about over at Future Market Insights.

The most obvious benefit of a fully automatic system is its sheer speed. These machines can label thousands of jars an hour. It’s a pace that manual or semi-automatic methods could never hope to achieve, making them necessary for large manufacturers supplying big retail chains.

But it’s not just about speed. These systems deliver impeccable consistency. Every single label lands in the exact same spot on every single jar, which is key for maintaining brand image and creating that all-important shelf appeal. This precision also slashes waste from misapplied labels and completely removes the chance of human error.

Another huge plus is the hands-off operation. Once it’s set up and running, the machine handles everything. This frees up your staff to focus on other valuable tasks, like quality control or managing logistics. Keeping these systems in prime condition is surprisingly straightforward with a good maintenance routine, and you can learn more about that in our guide on how to keep your fully automatic labelling machines running smoothly.

What Kinds of Labels Can They Handle?

One of the great strengths of a fully automatic labeller is its versatility. They aren’t just for one-piece wrap-around labels. These machines can be configured to handle more complex jobs, such as:

- Front-and-back labelling for jars that need separate branding and nutritional information.

- Top-and-bottom application for specialised containers or multi-part packaging.

- Tamper-evident seals that wrap over the lid, offering both security and peace of mind for the customer.

Today’s automatic labellers are remarkably adaptable. With just a few adjustments, they can be set up to handle a huge variety of jar shapes and sizes, from tiny cosmetic pots to big family-sized food jars. This flexibility means you can run different product lines through the same machine with very little downtime needed for changeovers.

So, whether you’re packing jams, cosmetics, or pharmaceuticals, a fully automatic system gives you the speed, accuracy, and reliability needed for high-volume production. It’s an investment that quickly pays for itself through higher output, lower labour costs, and a perfectly professional finish, every time.

Right, you’ve decided whether you need a manual, semi-automatic, or fully automatic labeller. But that’s just the starting line. Now comes the part where the details really matter-getting into the technical specifications so the machine you choose is a perfect fit for your products.

Think of it like buying a new set of tyres. You wouldn’t just grab any set off the shelf; you need the exact size and type for your specific car to run safely and efficiently. The same principle applies here. Making the wrong choice can lead to endless frustration and a machine that just doesn’t work for you.

First things first: can the machine actually handle your jars and labels? This is the most fundamental check. If a labeller can’t manage your product’s dimensions, it’s a very expensive paperweight.

It’s easy to get so focused on the jar that you forget about the label roll itself. I’ve seen people buy a fantastic machine, only to find out their label supplier uses 76mm cores and the new labeller only takes 40mm cores. It’s a simple detail, but one that can bring your entire production line to a halt. Always double-check.

The machine doesn’t just need to work with your jars; it has to be compatible with how your labels arrive from the printer. The physical makeup of the label roll is just as critical as the label itself.

This is a conversation you need to have with both your machinery supplier and your label printer before you buy anything. Make sure everyone is on the same page regarding core sizes, roll diameters, and winding directions.

To help you navigate these technical details, we’ve put together a checklist. Use this to compare different models and have a productive conversation with potential suppliers.

| Specification | Why It Matters | What to Look For |

|---|---|---|

| Label Size Range (H x W) | Makes certain the machine can apply your specific labels. | Check min/max height and width specs against your current and future label designs. |

| Jar Diameter/Shape | Confirms compatibility with your containers. | Look for the supported diameter range for round jars or compatibility with square/tapered shapes. |

| Labels Per Minute (LPM) | Determines production capacity and throughput. | Match this to your current and projected daily/weekly production targets. |

| Label Roll Core Size | The machine must fit the cardboard core your labels are wound on. | Common sizes are 40mm and 76mm. Confirm this with your label printer. |

| Maximum Roll Diameter | A larger diameter means fewer roll changes and less downtime. | Check the max outer diameter the machine’s spool holder can accommodate. |

| Machine Footprint (L x W x H) | It needs to physically fit in your workspace. | Measure your available space and compare it to the machine’s dimensions. |

| Power Requirements | Makes certain you can plug it in and run it safely. | Check if it needs a standard 240V outlet or a three-phase supply. |

Getting these technical points sorted from the outset turns a potentially risky purchase into a confident, informed decision. It’s the difference between buying a tool that helps you grow and a headache you’ll regret for years.

The world of labelling has moved far beyond just getting a sticker onto a jar. We’re seeing some genuinely exciting trends driven by what customers now expect and the constant need for brands to find a new edge. These shifts are opening up fresh ways to engage with people and handle products far more efficiently.

One of the biggest changes, and one that’s not going away, is the push for sustainable labelling. Shoppers are savvier than ever, actively seeking out products that reflect their own values. This has spurred on the creation of labels made from recycled materials and even biodegradable adhesives.

Another major leap forward is the arrival of ‘smart’ labels. These aren’t your average sticky paper; they often have Near Field Communication (NFC) or Radio Frequency Identification (RFID) chips embedded within them. It’s like giving every single jar its own tiny digital passport.

This kind of technology unlocks a huge range of possibilities for businesses of all shapes and sizes:

What was once the exclusive domain of massive corporations is now becoming accessible to medium-sized businesses, giving them a powerful new tool to make their products pop on a crowded shelf.

In the UK, the entire labelling technology sector, which includes label makers for jars, is undergoing a massive shift. This is really being driven by a twin focus on sustainability and smart tech. The market for sustainable labels in the UK is projected to hit £18 billion. That figure shows just how mainstream eco-friendly materials like plant-based films and compostable adhesives have become, pushed by new regulations and consumers demanding responsible packaging.

Of course, integrating these new types of labels demands precision. Smart labels, with their delicate embedded chips, can be a little thicker or more rigid than what you might be used to. This means your labelling machine has to be up to the task of applying them without causing damage or, crucially, misalignment.

Getting the machine setup just right is absolutely key. Even a tiny deviation can mess with the functionality of an RFID or NFC chip, rendering it useless. For some practical advice on nailing that perfect placement, you can find some excellent tips for troubleshooting labelling machine misalignments on our blog. When you get the application spot-on, you make certain these advanced labels can actually deliver on their exciting promise.

Picking the right piece of equipment always brings up a few questions. It’s completely normal. Getting those questions answered is the best way to feel confident in your choice and sidestep any headaches later on. Let’s walk through some of the most common things people ask when looking for label makers for jars.

This is probably one of the first things people wonder about, and for good reason. The short answer is: it varies by machine.

Most semi-automatic and fully automatic labellers are built for flexibility. They come with adjustable guides, rollers, or conveyor rails that you can tweak to fit a whole range of jar diameters and heights. A machine might, for example, be rated to handle jars from 20mm up to 100mm in diameter. You’ll want to dig into the technical specs to find this exact range before you buy. This little bit of homework confirms the machine will work for your current jars and any new sizes you might dream up in the future.

Manual applicators can be surprisingly versatile with odd shapes, but they have their own limits when it comes to size ranges. They might be great for a tapered honey jar, but each model is still designed for a specific spectrum of round container sizes. Always double-check that its capabilities cover your entire product portfolio.

We see it all the time: someone buys a machine that’s a perfect match for their main product, only to find out it can’t handle their tiny sample jars or a larger special-edition container. Checking the full operational range from the start will save you a world of trouble and expense.

This is a really important distinction, and it’s easy to get them mixed up. The machines we’ve been talking about in this guide are mostly label applicators. Their one job is to take your beautifully pre-printed labels from a roll and apply them perfectly onto your jars. You bring the finished labels, and the machine does the physical work of sticking them on. Simple as that.

A label printer-applicator is a more complex, two-in-one system. It has both a printing engine (usually thermal transfer or direct thermal) and an application arm. This allows it to print variable information-like batch codes, best-before dates, or unique serial numbers-onto a blank or partially printed label just seconds before it gets applied to the jar.

You typically see these systems in industries like pharmaceuticals or large-scale food manufacturing, where that kind of real-time data is needed for traceability. For most artisan producers or small to medium-sized businesses, a standard label applicator is more than enough to get the job done.

This is absolutely key. If your labels and your machine aren’t compatible, your production line will grind to a halt before it even gets going. Thankfully, you only need to get three key things right.

Just by communicating these three details to your label supplier, you can be confident that the rolls you order will fit and run smoothly on your new equipment. It’s a simple check that prevents some of the most common and frustrating setup problems.

Ready to find a labelling solution that fits your production needs perfectly? The expert team at Sessions UK is here to help you navigate the options and select the ideal equipment for your jars. Explore our extensive range of manual, semi-automatic, and fully automatic labelling machines today.

Copyright © 2025 Sessions Label Solutions Ltd.