When outfitting your business for shipping, one of the most important decisions is choosing the right label printer for shipping. For most companies, this boils down to one clear winner: the thermal printer. These workhorses create crisp, durable labels without needing a drop of ink or toner, making them the most cost-effective and reliable way to print smudge-proof barcodes and addresses.

If you still print labels on A4 paper with your standard office printer, making the switch to a dedicated label printer for shipping is a huge improvement. It’s a genuine step up in both professionalism and raw efficiency. A purpose-built label printer is designed to do one job and do it brilliantly, completely getting rid of the tedious and messy process of cutting out paper labels and wrestling with sticky tape.

This specialisation brings some serious benefits to your daily operations:

A dedicated printer transforms your shipping station from a bottleneck into a smooth, efficient part of your workflow. Instead of fighting with paper jams and smeared ink, you get a clean, professional label every single time.

The magic behind this efficiency is thermal printing. It is so effective, it currently commands over 45% of the market share in the global label printer market. This is not a niche technology; it is the industry standard for a reason.

With the market projected to soar to USD 836.4 million by 2035, it is clear that the demand for reliable shipping solutions is only growing. The rock-solid performance of thermal technology is precisely why it is the go-to choice for logistics experts and e-commerce businesses everywhere.

Picking the right device depends on your needs. Are you a small start-up shipping a handful of packages each day, or a larger warehouse with orders flying out the door? Your daily volume will be the biggest factor in your decision. Our complete guide to label printer shipping options can help you find the perfect match for your business.

When you are choosing a printer for shipping labels, it really boils down to two main technologies: thermal and inkjet. You probably already have an inkjet printer at home, but its purpose and function are worlds away from a dedicated thermal printer. Getting to grips with these differences is the key to making a smart investment for your business.

Inkjet printers operate by spraying microscopic droplets of ink onto paper. This is perfect for printing family photos or colourful documents, but it has some real drawbacks for shipping labels. The ink cartridges are notoriously expensive, the printed labels can easily smudge or run if they get wet, and the cost per label can quickly add up.

Thermal printers, as the name suggests, use heat to create the image on the label. This is where things get interesting, as the technology splits into two distinct types, each with its own strengths.

A direct thermal printer works its magic by using a heated printhead to directly activate special, chemically treated paper. As the label paper slides under the printhead, the heat triggers a reaction that turns the paper black, instantly forming your text, barcodes, and logos. The best part? No ink, no toner, and no ribbons are ever needed.

The main advantages here are simplicity and incredibly low running costs. Your only ongoing expense is the labels themselves. For a deeper look, check out this excellent guide to a thermal label printer for shipping. The one thing to keep in mind is that these labels can fade over time, particularly if they are exposed to direct sunlight or high heat. For standard shipping, where a label only needs to survive for a few days or weeks, this is rarely a problem.

Thermal transfer printers also use a heated printhead, but they add another element to the mix: a ribbon. Instead of heating the paper directly, the printhead melts a wax or resin-based ribbon onto the label’s surface. This “transfers” the ink to the paper, creating a far more durable and long-lasting print.

This process results in labels that are incredibly resilient, standing up to fading, chemicals, and general wear and tear. It makes thermal transfer the go-to choice for applications that demand longevity, like product identification barcodes or labels for long-term warehouse storage. The trade-off is a slightly higher cost per label, as you will need to buy ribbons in addition to the labels.

To make the comparison clearer, let’s break down the key features side-by-side.

| Feature | Thermal Printer | Inkjet Printer |

|---|---|---|

| Printing Method | Uses heat (direct or with a ribbon) | Sprays liquid ink droplets |

| Consumables | Labels (and ribbons for transfer) | Ink cartridges, paper |

| Cost Per Label | Very low | High |

| Print Speed | Very fast (prints in seconds) | Slower |

| Durability | High (smudge-proof, water-resistant) | Low (prone to smudging and water damage) |

| Maintenance | Minimal (occasional cleaning) | Frequent (head cleaning, cartridge changes) |

| Best For | High-volume shipping, barcodes | Colour documents, photos, occasional use |

This table really highlights why thermal printers are the standard for serious shipping operations. They are built for speed, efficiency, and durability where it counts.

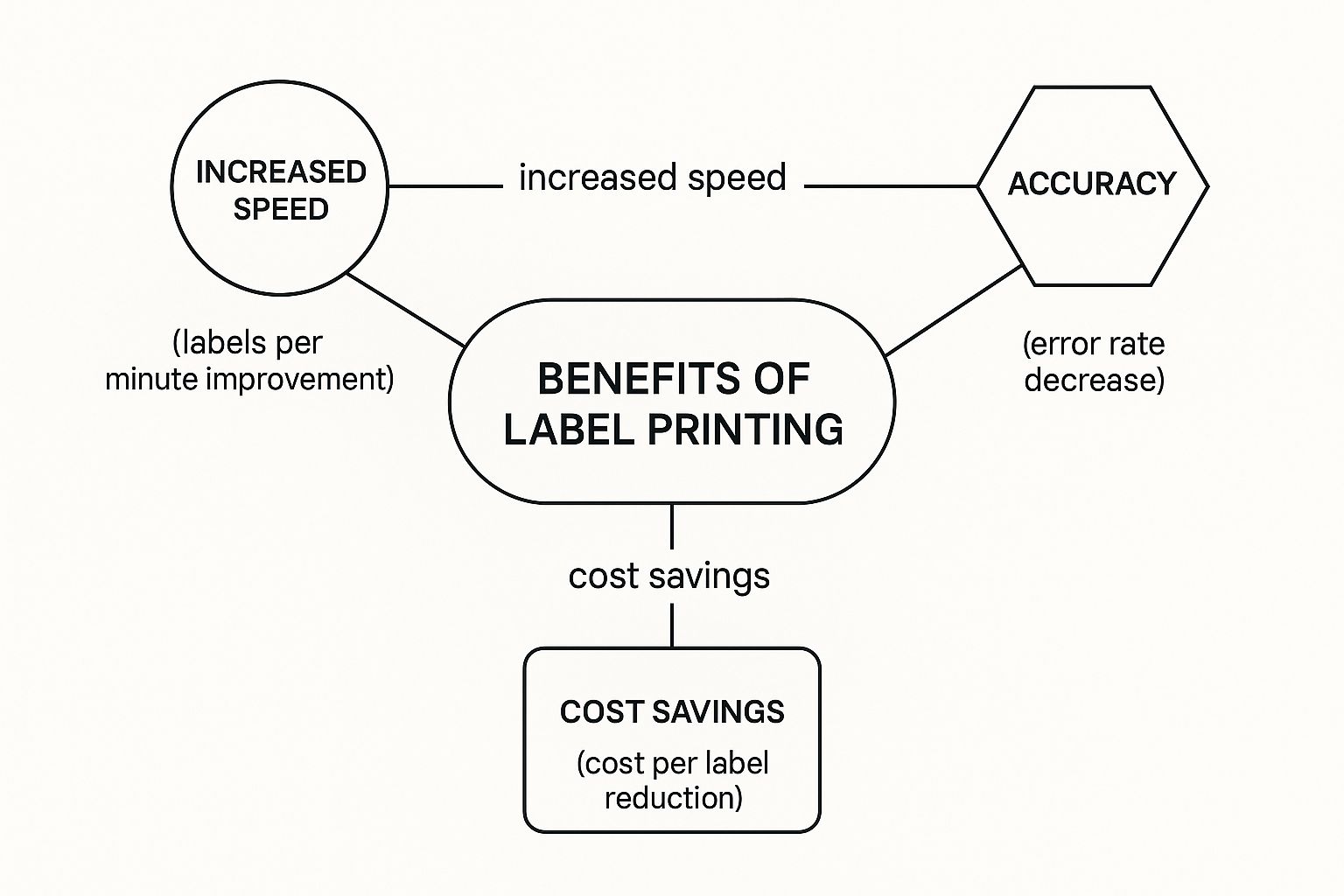

The image below gives a great visual summary of the core benefits you gain by switching to a dedicated label printer.

As you can see, making the move to a specialised printer delivers major improvements in speed, long-term cost savings, and the accuracy of your entire shipping process.

For most e-commerce businesses, a direct thermal printer offers the best balance of speed, cost, and convenience. It eliminates the recurring expense of ink and produces labels that are perfectly suited for the demands of the modern delivery network.

The right choice depends on what your business needs. If you are handling a high volume of parcels where speed and low costs are your top priorities, direct thermal is the undisputed champion. If your labels need to withstand harsh conditions and last for years, thermal transfer is the more durable and reliable solution.

Once you have settled on the right type of thermal technology for your business, it is time to dig into the details that separate a workhorse printer from a dud. These features are the nuts and bolts of your daily shipping workflow, impacting everything from how quickly you can get orders out the door to whether your barcodes actually scan.

The explosive growth of e-commerce in the UK is really fuelling the demand for this kind of hardware. The market for barcode printers-which includes your shipping label printer-is expected to hit around USD 750 million by 2035. This is not just a number; it shows how central efficient shipping tools have become. You can get a deeper look at this trend by checking out the United Kingdom barcode printer market research at futuremarketinsights.com.

When it comes to the performance of a label printer for shipping, two specs matter more than almost anything else: speed and resolution. One dictates your efficiency, the other your quality.

Print speed is typically measured in millimetres per second (mm/s). A higher number simply means more labels printed in less time, which is a lifesaver when you are dealing with a mountain of orders. An entry-level machine might chug along at 150 mm/s, but industrial-grade printers can fly past 250 mm/s.

Resolution, on the other hand, is all about clarity. It is measured in Dots Per Inch (DPI), and the industry standard for shipping labels is 203 DPI. This is perfectly fine for basic text and barcodes that scanners can read without trouble. If your labels include small text or a detailed company logo, stepping up to 300 DPI gives you a much sharper, more professional look and reduces the risk of a courier’s scanner failing to read your barcode.

Think of DPI like the resolution on a TV. A 203 DPI printer is like standard definition-it gets the job done. A 300 DPI printer is the high-definition equivalent, where every line is crisp and clear. That extra clarity can be the difference between a parcel sailing through the network and one getting stuck in limbo.

How your printer talks to your computer and software is just as critical as how it prints. Modern printers offer a few different ways to get connected, so you can find one that fits your workspace perfectly.

Beyond the physical connection, software compatibility is huge. Any decent label printer for shipping needs to play nicely with major UK couriers like Royal Mail, DPD, and Evri. It also has to integrate with the big e-commerce platforms like Shopify, eBay, and Amazon, so you can print labels directly from your order dashboard. This is where a simple printer transforms into a real automation powerhouse.

https://www.youtube.com/embed/dQnCaEHX0SI

So, you have just unboxed your new label printer for shipping. That is the first step to making your packing and dispatch process a whole lot easier. Getting from the box to that first perfectly printed label is actually quite simple, as long as you take it step-by-step. Most headaches come from tiny setup mistakes, so a bit of care now will save you a lot of time later.

First, let’s get it physically set up. Plug in the power cable and connect the printer to your computer with the USB cable that came with it. Before you even think about switching it on, pop the cover open and have a look inside. It’s a good idea to see exactly how the labels are meant to be loaded.

Whether you are using a big roll or a stack of fanfold labels, the path they follow through the printer is crucial. You will usually see a diagram inside that shows you the way. Make sure you thread the labels under the guides correctly and feed the first label just past the printhead. Once that’s done, you can close the cover.

Right now, your printer is just a box of plastic and electronics. Your computer has no idea how to talk to it, and that’s what drivers are for. Most printers will come with a USB stick or a link in the manual to download the correct driver for your operating system, be it Windows or macOS.

This part is key: you absolutely must install the driver before you plug the printer into your computer’s USB port. It might seem backwards, but following the manufacturer’s instructions here will save you from a world of common connection problems. Once the driver software is installed, go ahead, connect the printer and power it on. Your computer should now recognise it instantly and finish the setup.

With the printer connected and recognised, there’s one final, crucial step: calibration. This is where you ‘teach’ the printer the exact size of your labels, like the standard 4×6 inch shipping label. It needs to know where one label ends and the next one begins. If you skip this, you will end up with prints running across multiple labels or even completely blank ones being spat out.

Most printers make this easy. It is often just a case of holding a button down while you turn the printer on. The machine will then feed a couple of labels through, measuring the gap between them to get its bearings. Once that is done, your label printer for shipping is officially ready for action.

Think of your printer like a car. It needs a bit of regular attention to run reliably. Simple, periodic cleaning is the best way to keep it performing at its best and avoid frustrating downtime.

To keep everything ticking over, a little bit of upkeep goes a long way. For a deeper look at this, you can learn more about how to keep your fully automatic labelling machines running smoothly in our dedicated guide. The single most important maintenance job is cleaning the printhead.

Dust, dirt, and tiny bits of adhesive from the labels will inevitably build up on the thermal printhead over time. This is what causes those annoying white lines or gaps in your prints. To clean it, switch the printer off and unplug it completely. Open it up and gently wipe the printhead element with a soft cloth and a little isopropyl alcohol. Let it air dry for a minute before you close everything up and power it back on. A quick clean like this every now and then will keep your barcodes sharp and scannable.

A modern label printer for shipping is good, but it truly shines when it is linked directly to your sales channels. Manually copying and pasting customer addresses is more than just tedious; it is a surefire way to make mistakes that lead to lost packages and frustrated customers. The real goal is to create a link between your order list and your printer.

This connection is usually handled by shipping software or built-in integrations within your e-commerce platform. Instead of wrestling with labels one by one, your orders are pulled straight from your store. In just a couple of clicks, you can print an entire batch of accurate, courier-ready labels.

Let’s walk through a real-world example. Say a customer places an order on your Shopify store. The second that order hits your dashboard, all the necessary data is poised and ready. You just select the order, confirm the package weight, pick your courier, and the system instantly generates a perfectly formatted 4×6 inch label.

This simple workflow gets rid of almost all manual data entry. Gone is the risk of mistyping a postcode or swapping house numbers. For any online seller, getting this right is a big step forward. Understanding how to set up shipping on Shopify properly is the foundation for making this automated process a reality.

The UK’s label printer market is booming, driven by a growing need in retail and logistics for precise, compliant shipping labels. Advances in digital printing and automation are making it simpler than ever to sync printers with backend order systems, boosting both speed and quality.

Hooking up your systems delivers tangible, immediate benefits to your day-to-day operations. The leap in efficiency is huge, letting you get more orders out of the door in far less time.

The real value of an integrated setup is turning your shipping process from a manual chore into an automated function. It is the difference between being reactive to each order and having a system that works for you.

If you’re selling across multiple channels like eBay, Amazon, and WooCommerce, multi-carrier shipping software can pull all your orders into one central hub. This gives you a single point of control for creating all your labels. To learn more, check out our guide on printing postage labels. It is a setup that grows right alongside your business as you venture into new marketplaces.

Even with all the information out there, a few practical questions always pop up when it is time to actually choose and use a label printer for shipping. Let’s tackle some of the most common queries head-on to help you get your shipping setup running smoothly.

Technically, yes, you can. It is possible to print labels on a standard inkjet or laser printer using A4 paper. For any kind of business, it’s far from ideal. You’ll find yourself cutting out each label by hand and sticking it on with tape, which is not only slow but can also look a bit amateurish.

There’s a bigger issue: durability. Standard paper labels are fragile. They can easily get wet, smudged, or torn in transit. If that happens and the barcode becomes unscannable, you have got a lost package on your hands. A dedicated label printer uses tough, self-adhesive labels and is significantly faster and cheaper per label once you start sending out any real volume.

The go-to size for shipping labels across the UK is 4 x 6 inches (or about 10 x 15 cm). This is the industry standard used by virtually every major courier, including Royal Mail, DPD, Evri, and UPS.

Because it is the standard, most dedicated shipping label printers are built to handle this size. Sticking to it means everything-the address, tracking barcode, and any special instructions-is clear, legible, and easily scanned by the courier’s sorting machines.

A 4 x 6 inch label hits the sweet spot. It is large enough for all the crucial shipping info but not so big that it will not fit on smaller parcels. Using this standard size is the simplest way to avoid headaches and keep your packages moving without a hitch.

For most people, the answer is no. You won’t need to buy any specialised software. Modern e-commerce platforms like Shopify or marketplaces like Etsy have label printing built right in. The same goes for courier websites. They’ll format the label for you, and all you need to do is install your printer’s drivers on your computer.

If your business grows to handle huge volumes or works with lots of different couriers, you might look into dedicated shipping software to manage everything from one place. For the vast majority of sellers, the tools already provided by your sales platform are more than enough to get labels printed efficiently.

Nine times out of ten, poor print quality comes down to a dirty printhead or the wrong settings. The first thing you should always do is give the thermal printhead a clean. Over time, it gets clogged with dust and tiny bits of label adhesive, which causes those annoying white lines or gaps in your print. A quick, gentle wipe with an isopropyl alcohol wipe usually does the trick.

If that does not fix it, check your printer settings. Try bumping up the print darkness or slowing down the print speed-this often produces a much sharper result. It is also worth checking you are using good-quality thermal labels; cheap paper can lead to faint, inconsistent prints. If the barcode is still unreadable, double-check that your software is not accidentally stretching or distorting the label design, as this can make it impossible for scanners to read.

Ready to find the perfect labelling solution for your production line? Sessions UK offers a complete range of manual, semi-automatic, and fully automatic labelling machinery to meet the needs of any business. Explore our labelling machines today!

Copyright © 2026 Sessions Label Solutions Ltd.