Picking the right label printing rolls might seem a bit daunting, but it boils down to understanding three simple parts. I like to think of a label as a sandwich: it has a top layer you print on, a sticky middle bit, and a backing paper you peel away. Nail these three components, and your labels will be perfect for any job you throw at them.

It’s easy to see a label printing roll as just a reel of stickers, but it’s so much more. It’s a precisely engineered tool, built for a specific purpose. Each tiny part has a critical role in how the final label looks, feels, and performs. Getting this basic structure right from the start is your best bet for avoiding common headaches like peeling labels or fuzzy, unreadable prints.

These core components have to work in harmony. If one part isn’t right for the job, the whole system falls apart. Imagine printing a beautiful-looking label for a chilled product, only for it to fall off in the fridge because you chose the wrong adhesive. Suddenly, it’s useless for tracking or branding.

Every single label is made up of three distinct layers, and each one has a specific job to do. That sandwich analogy really helps to picture it.

This simple, three-part structure is the foundation of every label printing roll you’ll ever encounter.

By breaking down a label into these three parts-facestock, adhesive, and liner-you can make a much smarter choice. The key to success is matching each component to your specific needs, like the surface it’s sticking to or the environment it will have to survive in.

Once you have the physical makeup of the label sorted, the next piece of the puzzle is figuring out how you’ll get your information onto that facestock. There are two primary printing methods, and each one is suited to different kinds of tasks.

The first is direct thermal printing. This process uses a special, heat-sensitive paper that turns black when it passes under the printer’s hot printhead. There’s no ink, toner, or ribbon involved, which makes it incredibly simple and cost-effective to run.

The second method is thermal transfer printing. This technique is a bit different; it uses a heated printhead to melt a wax or resin ribbon directly onto the facestock, which creates the image. This produces a far more durable and long-lasting print that can handle some seriously challenging conditions.

Deciding between these two comes down to one simple question: how long does your label need to last, and what kind of environment will it be living in?

Picking the right material for your label printing roll is a bit like choosing the right tyres for a car. You wouldn’t fit slick racing tyres for a muddy off-road adventure, would you? It’s the same logic with labels. The material is the foundation, determining whether your label will survive its journey-be it a short trip in a delivery van or a long, hard life in a factory.

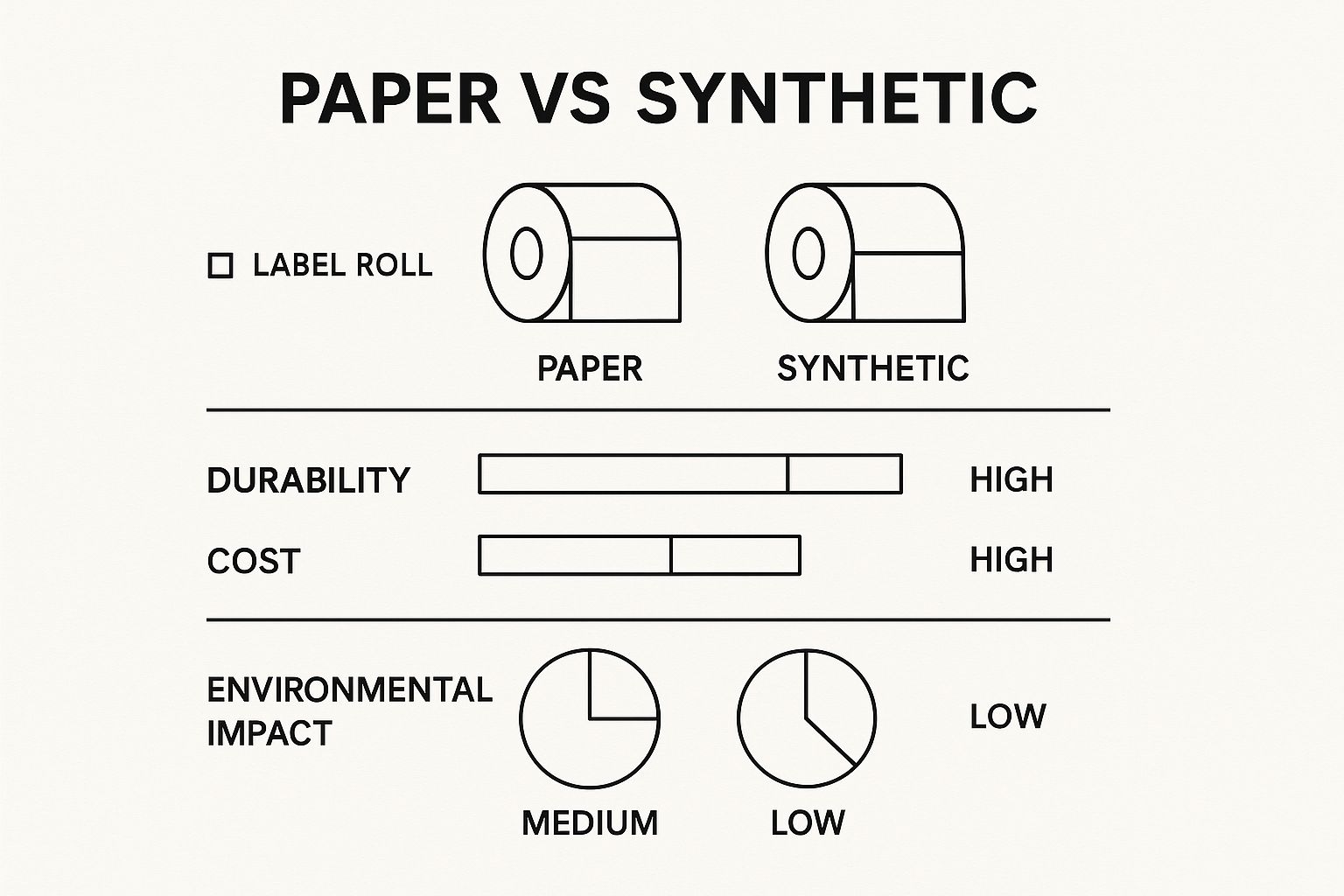

The choice really boils down to two main families: paper and synthetics. Each has its own strengths and is suited for very different jobs. A basic paper label is often the go-to for general-purpose tasks like shipping parcels, where its lifespan is short and sweet. They’re cost-effective and do the job perfectly for temporary applications.

Synthetic labels are the tough guys. Materials like polypropylene and polyester are built from the ground up to resist moisture, chemicals, and general wear and tear. This makes them the only real choice for labelling workshop equipment or products destined for the fridge.

There’s a good reason paper is the most common material for label printing rolls. It hits that sweet spot between decent print quality and affordability, making it the undisputed champion for high-volume, short-term use. For countless businesses, from small e-commerce shops to warehouses, paper labels are the reliable workhorse.

Their biggest advantage is, without a doubt, their low cost. When you’re churning out thousands of shipping labels every day, saving even a fraction of a penny per label makes a massive difference to your bottom line. They’re also perfect for simple product identification, price tags, and general admin tasks where the label won’t face any harsh conditions.

But paper has an Achilles’ heel: it’s not very durable. It’s vulnerable to tearing, scuffing, and any kind of moisture. A single splash of water or a bit of rain can turn a perfectly good barcode into an unreadable smudge, which is a disaster for logistics and tracking.

As you can see, while paper wins on price, synthetic materials are in a different league when it comes to durability.

When a label needs to do more than just survive a trip in a cardboard box, you need to turn to synthetics. These aren’t your average stickers; they are engineered plastics designed to withstand the rough and tumble of demanding environments.

The two most popular players in the synthetic world are polypropylene and polyester.

To help you get a clearer picture, here’s a quick comparison of the most common materials and where they shine.

| Material | Key Characteristics | Best For | Durability Rating |

|---|---|---|---|

| Paper | Low cost, good print quality, non-durable | Shipping labels, price tags, indoor use, short-term applications | ★☆☆☆☆ |

| Polypropylene | Water & oil resistant, flexible, more durable than paper | Food & beverage, cosmetics, products with curved surfaces | ★★★☆☆ |

| Polyester | Extremely durable, resists heat, chemicals & abrasion | Asset tagging, outdoor equipment, industrial & automotive parts | ★★★★★ |

This table should give you a solid starting point for figuring out what will work best for your products and environment.

The UK label printing market is booming, driven by sectors like logistics and manufacturing that need these kinds of specialised solutions. The explosion in e-commerce, in particular, has ramped up the demand for high-performance labels for everything from dispatch to product identification. You can learn more about the UK’s label printer market trends to see how the industry is evolving.

The real question isn’t about which material is ‘better’ overall, but which is the right one for your specific job. Taking a moment to think about your product’s lifecycle and its environment is the secret to making a smart, cost-effective choice.

Opting for a synthetic label is an investment in reliability. Yes, the initial cost is higher than paper, but it saves you from the headache and expense of re-labelling down the line. It makes certain that critical information stays put, which can prevent costly logistical nightmares. A food producer, for example, would be wise to choose a moisture-resistant polypropylene for a refrigerated product to stop labels from peeling off in the cold. A little foresight goes a long way.

The material of your label printing rolls is only half the story. The real hero is the adhesive-that invisible layer doing all the hard work. Get it wrong, and you’ll have labels peeling off mid-shipment. Get it too right, and you could damage a product or leave behind a tacky residue that frustrates your customers.

Choosing the right glue is all about understanding the label’s entire journey. Does it need to stay put forever? Does it need to peel off cleanly? Or does it need to be moved around a bit? Knowing the three main types of adhesives is the first step to making sure your labels stick exactly how you want, for as long as you need.

Most label adhesives, with countless special formulas, fall into one of three main categories. Each one is designed for a specific job, offering a different level of bonding strength and performance.

The key is to match the adhesive to the job. A permanent sticker on a delicate gift box is a recipe for disaster, just as a removable one on a critical safety warning would be dangerously irresponsible.

A label’s surroundings can make or break its adhesive’s performance. Two culprits, in particular, can turn a perfectly good label into a peeling failure: temperature and moisture. An adhesive that works brilliantly in a comfortable office might give up completely inside a freezer or on a humid factory floor.

For instance, a standard permanent adhesive can become brittle and lose its grip in the cold. That’s why frozen food packaging requires a specialist freezer-grade adhesive, which is formulated to stay sticky even at sub-zero temperatures. It guarantees the label remains secure all the way from the production line to the customer’s freezer.

The surface a label sticks to is just as important as the environment. A rough, porous surface like untreated cardboard needs a very different type of adhesive than a smooth, slick surface like glass. You have to match the glue to the surface energy of the material to get a reliable bond.

To pick the right adhesive, you need to think through the entire life of your label. What surface will it stick to? What temperatures will it endure? And is it a temporary guest or a permanent resident? Getting this wrong can lead to failed deliveries, lost stock, or simply a bad customer experience. For a deeper look, our comprehensive guide to understanding label adhesives has all the details you’ll need.

Here’s a quick checklist to guide you:

Answering these questions will point you straight to the perfect adhesive, making sure your label printing rolls perform flawlessly every single time.

Picking the right label material and adhesive is a huge part of the process, but it’s only half the battle. The final piece of the puzzle is actually getting your design onto the label. For that, you’ll likely be using one of two technologies: direct thermal or thermal transfer printing.

They might sound alike, but they work in completely different ways and are built for very different jobs. Understanding the distinction is the key to getting it right.

Think of it this way: a direct thermal label is like a receipt you get from a supermarket till. The printer uses a special heat-sensitive paper that turns black when heat is applied. Thermal transfer is more like using a classic typewriter with an ink ribbon. The printhead heats a ribbon, which then transfers that ink onto the label itself.

Direct thermal printing is a brilliantly simple process. The whole system relies on a special, chemically treated paper that darkens when it comes into contact with a heated printhead. That’s it. There’s no ink, no toner, and no ribbon needed, which makes these printers incredibly straightforward to run and look after.

This simplicity is its biggest selling point. With fewer moving parts and no ribbons to swap out, the overall running costs are often lower. This makes it a go-to choice for any job where the label has a short and sweet lifespan.

You’ll see direct thermal labels used for:

The main downside? Direct thermal labels don’t age well. They’re very sensitive to light and heat. Over time, or if left in the sun, the whole label can darken, making the text or barcode impossible to read. They also scuff easily, which can mess up the print quality.

Thermal transfer printing takes a much more durable approach. Instead of using heat-sensitive paper, it uses a ribbon made of wax, resin, or a blend of the two. The printer’s printhead heats the ribbon, melting it directly onto the label’s surface to create a crisp, tough image.

This method produces a much hardier print that’s built to last, even in challenging conditions. The finished labels are resistant to chemicals, moisture, scuffs, and extreme temperatures. This makes thermal transfer the only real choice for jobs that demand longevity and resilience.

The core difference is durability. Direct thermal is for temporary use, while thermal transfer creates a permanent mark. For any label that needs to last more than six months or survive tough conditions, thermal transfer is the only reliable option.

This resilience makes thermal transfer perfect for:

With various pressures, the UK label printing industry remains strong, largely because of its role in logistics and product safety. Discover more insights about the resilience of the UK label printing sector. The durability offered by thermal transfer printing is a major reason for this stability.

To help you decide, here’s a straightforward breakdown of how the two technologies stack up.

| Feature | Direct Thermal | Thermal Transfer |

|---|---|---|

| Consumables | Heat-sensitive labels only | Labels and ribbons |

| Initial Cost | Generally lower printer cost | Higher printer cost |

| Ongoing Costs | Higher label cost, no ribbon cost | Lower label cost, plus ribbon cost |

| Print Longevity | Short-term (under 6 months) | Long-term (years) |

| Durability | Sensitive to heat, light, and scuffs | Resistant to chemicals, heat, and moisture |

| Best For | Shipping, receipts, short-life items | Asset tags, product labels, outdoor use |

The choice comes down to your specific needs. If you’re looking for a simple, cost-effective solution for short-term labelling, direct thermal is a fantastic choice. But if you require durable, long-lasting labels that can take a beating, then thermal transfer is the superior technology, hands down.

Remember, the type of printer you use dictates which label printing rolls you can buy, so this is a foundational decision. You can learn more in our guide to choosing label printing machines to help match the right hardware to your needs.

It’s a frustratingly common mistake: you buy a fresh roll of labels, go to load it, and realise it won’t fit your printer. Production grinds to a halt, and you’re left with a roll you can’t use. The good news? This is an easy problem to avoid once you know exactly what to look for in your label printing rolls.

Every label printer, from the small desktop models to the big industrial machines, is built to handle specific roll sizes. If you try to jam in a roll that’s too wide or has too large a diameter, you’re just asking for misfeeds and printing errors. Getting these details right from the start saves a world of trouble down the line.

To get a perfect fit every time, you only need to get familiar with three key dimensions. These are the non-negotiable specs that dictate whether a roll will physically work with your hardware.

So, where do you find these numbers for your printer? It’s usually straightforward. Check the user manual, look on the manufacturer’s website, or sometimes there’s even a handy sticker with the specs right inside the printer’s cover.

Beyond just fitting inside the machine, your label printing rolls also have features that help the printer feed everything through correctly. These little details are crucial for getting clean, consistent prints and avoiding a pile of misaligned, wasted labels.

The two most common alignment aids you’ll see are perforations and sensing marks. Both give the printer’s sensors a physical cue to work with.

Getting the roll size and alignment features right isn’t just about compatibility-it’s about efficiency. The correct specifications prevent wasted labels, reduce printer errors, and keep your operations running without unnecessary interruptions.

Perforations, for instance, are the small tears between each label. Not only do they make the labels easy to separate by hand, but they also create a gap that many printer sensors use to detect where one label ends and the next begins. This is particularly useful in sectors like the clothing industry. You can learn more about how this works for specific applications like label printing for clothing.

The other common feature is a sensing mark (sometimes called a black mark or eye mark). This is a solid black line printed on the backing paper that a sensor reads to find the start and end of each label. It’s a lifesaver when you’re working with clear labels or odd shapes where a standard gap sensor would get confused. Knowing whether your printer uses gap or black mark sensing is central to buying the right type of roll.

The world of label printing rolls is moving in some exciting new directions, pushed forward by two major forces: a real desire for sustainability and the need for smarter, more interactive technology. Here in the UK, we’re seeing a shift that’s more than just skin deep. It’s fundamentally changing what a label is and what it can do.

It’s no longer enough for a label to just look good. Brands and their customers are demanding greener options that cut down on waste and lighten the environmental load, marking a clear move away from the old single-use mindset.

One of the biggest developments on the scene is the linerless label roll. Think about traditional labels – they all have that shiny, silicone-coated backing paper that you just peel off and throw away. Linerless rolls get rid of that backing completely, which is a huge win for the environment.

Not only does this cut landfill waste, but it also means you can fit up to 50% more labels onto a single roll. For any busy operation, that means fewer roll changes, less downtime, and even lower shipping costs. We’re also seeing a rise in new, greener materials like plant-based adhesives and label faces made from recycled paper or compostable films.

At the same time, labels are getting a serious intelligence upgrade. They’re evolving from simple static identifiers into interactive, digital platforms. This is happening through the integration of technologies like QR codes and Radio-Frequency Identification (RFID) tags directly into the label printing rolls.

A smart label acts as a gateway between a physical product and digital information. It allows for real-time inventory tracking, instant product authentication to combat counterfeits, and direct engagement with customers through their smartphones.

Imagine a customer scanning a QR code on a bottle of wine to watch a video about the vineyard it came from. Or picture a warehouse where an entire pallet’s contents can be scanned in a split second using an RFID reader, saving hours of manual counting. That’s the power of smart labels in action.

This double-act of sustainability and technology is quickly becoming the new industry standard. In fact, the sustainable labels market in the UK is expected to hit around £18 billion by 2025, which shows just how seriously everyone is taking this. You can discover more about the future trends in labelling technology to see how these ideas are shaping the industry.

These intelligent, eco-friendly labels give businesses powerful new ways to manage their supply chains and create a much deeper connection with their customers.

Even when you have the basics down, a few practical questions always seem to pop up when you’re working with label printing rolls. Getting the right answers can save you from costly mistakes and frustrating downtime. Let’s tackle some of the most common queries we hear from our clients.

A big one is about the lifespan of thermal labels. Direct thermal labels don’t last forever. Because they’re sensitive to heat and light, you need to store them somewhere cool and dark. If you do, you can typically expect them to stay in good shape for about one year before the special coating starts to break down.

This is a really common trip-up, but it all comes down to simple mechanics. Think of it like trying to fit a lorry tyre on a bicycle – it just won’t work. A big roll with a 76mm core physically won’t fit onto a desktop printer’s spindle, which is built for a much smaller 25mm core.

Likewise, a roll with a massive outer diameter will never fit inside the housing of a compact printer. The best thing you can do is always check your printer’s spec sheet for its maximum roll diameter, core size, and label width before you order anything. A quick check saves a lot of headaches later.

Here’s a handy rule of thumb: If the label only needs to last days or weeks (like a shipping label), paper is almost always fine. But if it needs to survive for months or years, or face rough handling and moisture, a synthetic material is your best bet.

Deciding between paper and synthetic materials really boils down to two things: how long the label needs to last and what kind of environment it will be in. For short-term, indoor jobs like address labels, paper is a great, cost-effective choice.

But for something like a product label that might get wet, scuffed, or needs to stay readable for years, spending a little more on a durable synthetic roll is a wise investment. It makes certain that critical information stays put for the entire life of your product.

For expert advice on choosing the right labelling machinery and supplies for your business, contact Sessions UK. Find your perfect solution at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.