Label printing software is the central nervous system for your labelling operation. It is the smart link between your product databases – be they simple spreadsheets or a full-blown company-wide system – and your printers, making sure the right data gets onto the right label, every single time.

Think of it as an air traffic controller, but for your product information. Instead of just designing a static picture, this software directs a constant flow of data from all your sources straight to your printers. It’s what prevents the chaos and costly mistakes that happen when you are manually typing in details for every single label.

This is a world away from using standard design programs. Good label software handles complex jobs on autopilot, like generating unique barcodes for each item, pulling real-time data for expiry dates, or printing customised labels across a whole network of machines. You can get a deeper look by reading our complete guide to software for labels printing.

At its heart, the software’s main job is to bridge the gap between your data and the physical label you hold in your hand. It acts as a translator, taking raw information from a database and formatting it perfectly for a specific label template and printer.

Imagine a food producer. They can connect their software directly to their production database. When a new batch of jam comes off the line, the software automatically pulls the correct:

This data is then fired off to the printer, resulting in an accurate, compliant label without anyone having to type a single character. This direct link is what truly separates professional labelling tools from basic design apps.

A dedicated label printing system is built to handle dynamic, changing information. It shifts a business from a manual, error-prone process to an automated, reliable workflow for identifying and tracking products.

Across UK industries like manufacturing, retail, and healthcare, the pressure for efficient and compliant labelling has never been higher. Businesses are turning to these solutions to keep up with strict regulations around product safety and traceability. Market analysis shows that the efficiency boost from this kind of software can slash labelling errors by up to 30%, which has a huge knock-on effect on inventory accuracy.

This move towards automation is all about helping companies stay accurate while juggling thousands of product variations – a near-impossible task to manage by hand.

Good label printing software is so much more than a design program. It’s the engine room of your labelling operation, packed with features that deliver real, measurable results for your business. Once you understand these core capabilities, you start to see how the right software is not just about making labels look good; it is about making your entire process sharper, more accurate, and more secure.

These features all work in concert to slash manual work, get rid of costly mistakes, and lock in consistency across every single product you ship. Let’s look at the functions that really make a difference.

The best label software always comes with a user-friendly design interface. What this means in practice is that your team can create professional, fully compliant labels without needing weeks of intensive training. Think of it like using the office software you’re already familiar with, but with specialised tools built for the job.

This ease of use goes hand-in-hand with powerful template management. Instead of starting from scratch for every product variation, you design one master template. The software then pulls in the right data for each specific item. It’s a simple concept, but it is fundamental for keeping your branding consistent and your regulatory compliance in check.

Imagine a medical device company. They can create a locked template that meets strict MHRA standards. Crucial elements like warning symbols and compliance marks can be fixed in place, meaning an operator can’t accidentally delete or change them. Suddenly, the label is no longer just a sticker; it is a controlled document, protecting the company from serious compliance failures.

The goal of a good interface and template system is simple: permit your team to create what they need, while putting guardrails in place to prevent mistakes. It’s that perfect balance of flexibility and control.

Today’s supply chains are built on barcodes. Any quality label printing software will offer comprehensive support for all major 1D and 2D barcode types, whether that’s standard EAN codes for retail shelves or complex QR codes for end-to-end traceability. The software takes care of the technical side, so you can be confident you’re getting scannable, reliable barcodes every time.

But this feature truly comes alive when you pair it with database connectivity. By linking the software directly to your business data – whether it’s in a spreadsheet, an SQL database, or your main ERP system – you completely remove the need for manual data entry. This is, without a doubt, the single most effective way to eliminate human error on your production line.

Let’s look at a food producer with hundreds of products, each with different expiry dates and batch codes.

This kind of automated workflow prevents a catastrophic product recall that could be caused by a simple typo in a date. For any business where data accuracy is non-negotiable, this isn’t a nice-to-have; it is a necessity. Data connectivity turns your labelling process from a potential weak spot into a source of rock-solid reliability.

Certain features are the bedrock of an effective labelling system. The table below summarises the must-haves and explains exactly why they matter for your business operations.

| Feature | Description | Primary Business Benefit |

|---|---|---|

| Design Interface | A user-friendly, drag-and-drop editor for creating label layouts with text, images, and barcodes. | Reduces training time and allows staff to create labels. |

| Template Management | Allows creation of master templates with locked and variable fields to maintain consistency. | Enforces brand and regulatory compliance across all labels. |

| Database Connectivity | Directly links label templates to business data sources (ERP, SQL, spreadsheets) for automatic data fill. | Drastically reduces human error from manual data entry. |

| Barcode Support | Full library of all standard 1D (EAN, Code 128) and 2D (QR, Data Matrix) barcode symbologies. | Confirms scannability and compatibility across supply chains. |

| Printer Integration | Native drivers and support for a wide range of thermal transfer, inkjet, and laser printers. | Guarantees reliable, high-quality printing without issues. |

| Regulatory Compliance | Tools and templates to help meet industry-specific standards (e.g., GHS, UDI, Natasha’s Law). | Mitigates risk of fines and product recalls. |

| User Access Control | Ability to set permissions for different user roles (e.g., designer, operator, administrator). | Secures the labelling process and prevents unauthorised changes. |

These core functions work together to transform labelling from a manual, error-prone task into a controlled, automated, and reliable part of your production workflow.

Your label printing software should never operate on an island. Real efficiency is not just about printing faster; it is about connecting with the business systems you already rely on every day, like your Enterprise Resource Planning (ERP) or Warehouse Management System (WMS).

This connection is what turns labelling from a standalone manual task into a fully integrated part of your business workflow. Instead of an operator manually re-typing information from one screen to another, the software pulls data directly from a central source of truth. It creates a reliable, automated chain of events that just works.

Imagine this: an order gets marked as ‘ready to ship’ in your ERP. That single action can automatically trigger the printing of the perfect shipping label, complete with the right address, order number, and tracking details. No human intervention needed. This simple link virtually eliminates the risk of costly address mistakes.

The magic behind all this is something called an API, or Application Programming Interface. The easiest way to think of an API is as a universal translator. It’s a bit of code that allows completely different software programs to speak the same language and share information securely.

This translator works behind the scenes, building a bridge between your core systems and your label software. It’s how your WMS can tell the labelling software exactly which product is being picked, so the correct label with the right barcode is printed at the right packing station, at the right time.

This level of integration is really what separates a professional solution from a basic one. It establishes a single, cohesive workflow where actions in one system cause predictable, automated results in another. That saves a huge amount of time and prevents countless errors.

A well-integrated system means that your label printing process is no longer a potential bottleneck. Instead, it becomes a responsive and intelligent part of your entire supply chain, reacting in real time to business events.

The UK’s label printing industry has a long history of evolving with new tech and market demands. As part of a wider packaging and printing sector valued at over £14 billion, the move towards digital solutions really picked up pace in the early 2010s. The adoption of proper label printing software grew rapidly, making on-demand printing and customisation possible in ways older methods just could not support economically.

Between 2015 and 2020, the UK saw double-digit annual growth in the use of this software, mirroring trends across Europe. You can find more insights on the global market over at FutureMarketInsights.com.

This history just goes to show how critical it is to choose software that is built for connectivity. As your business grows and your systems get more complex, your label printing software has to keep up, communicating effectively with every part of your operation, from inventory all the way through to final dispatch.

Picking the right label printing software can feel like a huge task, but breaking it down makes it much more straightforward. The best choice for you hinges entirely on the realities of your business – its size, your industry, and the day-to-day demands you face. A small startup’s labelling needs are a world away from those of a massive enterprise, and recognising that difference is the first step.

The trick is to find software that solves your actual operational problems, not just one with a long list of flashy features you will never touch. The goal is a solution that slots neatly into your current workflow and has the legs to grow with you.

Before you even glance at a single software demo, take a hard look at your own requirements. A local business printing a few hundred shipping labels a day has a completely different set of priorities than a pharmaceutical company, which has to meet incredibly strict regulatory standards on every single product.

Think about your specific sector. If you are in logistics or warehousing, you are probably focused on speed and how well the software talks to your Warehouse Management System (WMS). If you are in the food and beverage industry, your main concerns might be robust tools for managing allergen information and tracking expiry dates.

The best label printing software is not the one with the most bells and whistles; it is the one that solves your specific challenges. A solid grasp of your print volume, compliance obligations, and existing systems is the compass that will point you to the right solution.

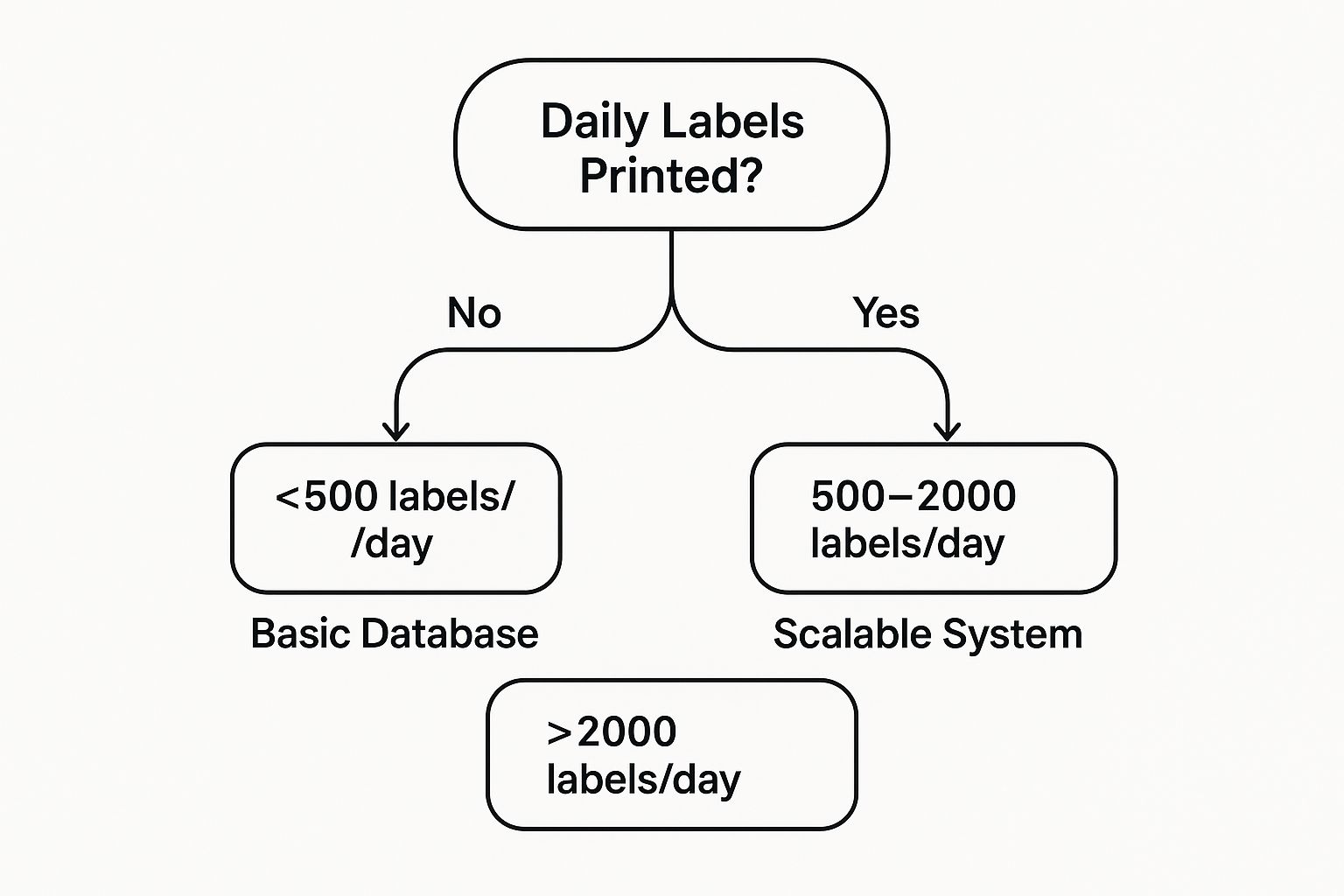

The image below gives you a sense of how your daily label volume can help narrow down the type of system you should be looking at.

As you can see, the higher your output, the more critical it becomes to have sophisticated database connections and powerful management tools.

To help frame your decision, here’s a look at how different-sized businesses might approach the selection process.

| Selection Criterion | Considerations for Small Business | Considerations for Enterprise |

|---|---|---|

| Budget | Prefers low upfront cost; subscription models are often ideal. | Focused on Total Cost of Ownership (TCO) over 3-5 years. |

| Integration | Needs simple connections, perhaps to e-commerce platforms like Shopify or basic accounting software. | Requires deep, complex integrations with ERP, WMS, and bespoke legacy systems. |

| Scalability | Needs a solution that can handle gradual growth without a complete overhaul. | Demands a system that can scale across multiple sites, countries, and production lines. |

| Support | Requires accessible, easy-to-understand support, often via email or chat. | Needs 24/7 priority support with guaranteed response times for critical production issues. |

| Compliance | May need to meet basic industry standards (e.g., food labelling). | Must adhere to strict, often global, regulatory standards (e.g., GHS, UDI, FDA). |

This comparison highlights that there is no “one-size-fits-all” answer. The right choice is always the one that aligns with your specific operational scale and complexity.

Once you have a clear picture of what you need, it is time to start talking to vendors. Go into those conversations armed with a list of direct questions to cut through the sales pitch and get to the information that actually matters.

Here are a few non-negotiables to ask:

Getting straight answers here is critical. Dependable technical support, for instance, can be an absolute lifeline when a production line grinds to a halt. Likewise, fully understanding the total cost of ownership helps you avoid nasty financial surprises down the road. For many businesses, pairing their new software with an automatic labeler machine is the final piece of the puzzle, creating a truly efficient production line.

You are looking for a partner, not just a product. The right vendor will offer a solution that feels like a natural extension of your operation and provides reliable backup when you need it most. This careful groundwork means you end up with a tool that genuinely makes your business run better.

When you bring dedicated label printing software into your business, the impact goes straight to the bottom line. It’s about much more than just printing neat labels; you’ll see positive ripple effects across your entire operation, from the production floor right through to dispatch. These are real, tangible results that make a compelling case for investing in a proper labelling system.

One of the first things you will notice is a huge drop in human error. We have all seen it happen – manual data entry is a minefield for mistakes that can lead to mislabelled products, packages sent to the wrong address, or even the nightmare scenario of a product recall. By automating data pulls directly from your business systems, the software simply takes that risk off the table.

Think about a busy distribution centre. It can pretty much eliminate miss-shipments by linking its label printing software to its order management system. An order comes in, it gets processed, and the correct shipping label prints out automatically. No one has to copy and paste a single address. That one change saves money, protects the company’s reputation, and keeps customers happy.

Another massive win is the sheer speed of it all. Automated print jobs are worlds away from manual ones, letting your team push more orders out the door in less time. It’s not just about printing one label faster; it is about creating a smooth, continuous flow that stops the production line from getting bogged down.

And let us not forget about accurate barcoding, a core feature of any good system. It completely changes the game for inventory tracking and supply chain visibility. Every time a barcode is scanned, you get a reliable piece of data, giving you a live, up-to-the-minute picture of stock levels and where your products are.

When you implement a modern labelling solution, what was once a simple admin task becomes a strategic asset. You get the accuracy you need for compliance, the speed you need for efficiency, and the data visibility you need to make smart business decisions.

Staying on the right side of industry regulations is a constant headache for many businesses, particularly in sectors like food, medical, and chemicals. The right software makes this so much simpler by using locked templates and centralised data. You can design labels that meet specific standards and rest easy knowing every single one printed is correct.

The consistency you get from professional software is also a cornerstone of operational excellence. For a deeper look on this, you can learn about the importance of clean labelling for production and procurement in our related article.

So, what are the key business gains?

When you add it all up, it’s clear that investing in the right label printing software is not a cost – it is an investment that delivers a measurable return.

It’s completely normal to have questions when you’re looking at a new piece of business kit. Getting your head around the specifics of label printing software is the first step to understanding its real value and how it can slot into your day-to-day operations. Let us clear up a few of the most common queries.

Once you have a solid grasp of what the software does, how it works, and why it is a different beast from other tools, choosing the right one becomes much easier.

In theory, you could knock up the visual part of a label in a standard graphic design program. But that’s where the similarities end. These tools just do not have the muscle for proper business labelling.

Dedicated software is built from the ground up to link directly with your databases. This means it can automatically pull in dynamic data like batch codes, expiry dates, or unique shipping addresses without anyone having to type them in manually. That connection alone prevents a world of costly human error. It also has built-in support for every barcode type under the sun and knows how to ‘talk’ to specialised label printers, correctly handling settings for different label stocks and sizes.

For accurate, efficient, and compliant labelling, there is really no substitute.

Think of it this way: Graphic design tools create a picture of a label. Professional label printing software creates an intelligent, data-driven workflow that produces the right label, every time.

The main distinction boils down to where the software actually lives and how you pay for it.

The right choice often depends on your company’s IT infrastructure, budget, and how much you need your team to access it from different locations.

This is where dedicated software really shines. For anyone in tightly regulated industries like food, medical devices, or chemicals, label printing software is a necessary compliance tool. It helps you create locked-down templates that prevent unauthorised users from accidentally (or intentionally) changing an approved, compliant design.

By connecting to a single, central database, it confirms all the mandatory information – like allergen warnings in bold or specific safety symbols – is always accurate and present on every single label. The software can also provide a full audit trail, showing you exactly who printed what and when, which is absolutely critical for product traceability and accountability.

For the best results, yes. Most professional label printing software is designed to work hand-in-glove with dedicated label printers, like direct thermal or thermal transfer models. These machines are built to handle the demands of industrial use, producing durable, high-quality barcodes and crisp text that will last.

While some software might have limited support for a standard office printer, you’ll be missing out on the reliability, speed, and professional finish. Before you commit, always check the software’s list of supported printer drivers to make sure it plays nicely with the hardware you have or plan to buy. You can explore more general topics in our Frequently Asked Questions section.

For tailored advice on finding the right labelling machinery and software to match your specific production needs, talk to the experts at Sessions UK. Discover our full range of solutions at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.