Picture a production line where labelling is instantaneous and flawless, every single time. That’s precisely what a print and apply label system delivers. These smart machines print variable information-like barcodes, batch codes, or shipping details-onto a label and, in the same fluid motion, place it directly onto a product, case, or pallet.

At its heart, a print and apply label system is an automated machine that handles the entire labelling process from start to finish. It prints the required information onto a blank label and then immediately sticks it onto an item as it moves down the line.

This elegant solution gets rid of the manual labour that often creates bottlenecks and costly mistakes in a busy production environment. Think of it as your most reliable employee, one that works at incredible speed without ever getting tired or making an error.

These systems are a cornerstone of modern manufacturing and logistics here in the UK, directly tackling the need for speed, accuracy, and absolute consistency. By merging two key steps-printing and applying-they guarantee every item, whether it’s a food container or a massive shipping pallet, gets the right label in the right place, every single time.

The fundamental job of these machines is to take data from a source, print it on a label, and apply it to a product, all without anyone needing to lift a finger. This single, automated action drives several massive operational improvements:

Print and apply systems are a perfect example of how targeted technology can have a huge impact on efficiency. To get a broader sense of how this works, it’s worth understanding the fundamentals of process automation and the advantages it brings to UK businesses.

In short, these systems are the physical link between your digital information and your actual products. They take data from your company’s software and turn it into a readable, scannable label that’s securely fixed to your goods, all in a matter of seconds. It’s a foundational piece of the puzzle for any modern supply chain.

To really get a feel for how print and apply labelling systems work their magic on a busy production line, it helps to look under the bonnet. Think of them less as a single machine and more as a team of specialists working in perfect sync to perform one critical task: getting the right label onto the right product, every single time.

Let’s break down the core components. Each has a specific job, and understanding them helps to see how these systems achieve such remarkable speed and accuracy.

You’re looking at three main elements that define what the machine can do and how it does it.

First up is the print engine. This is where the label itself is actually born. It’s an industrial-grade printer, usually using thermal transfer or direct thermal technology, that creates all the high-resolution text, barcodes, and graphics needed.

This isn’t your average office printer. The print engine is a real workhorse, built to run non-stop in demanding factory environments. Its reliability is everything-if it goes down, your labelling stops dead.

If the print engine is the heart, then the controller is definitely the brain. This is usually a PLC (Programmable Logic Controller) or a dedicated industrial computer that acts as the conductor for the whole orchestra. It links up with your factory’s software-like a Warehouse Management System (WMS)-to pull the correct data for each and every label.

The controller tells the print engine what to print and when to print it. It also directs the applicator, ensuring the label is applied at the precise moment a product passes by. It’s this digital brain that guarantees perfect timing and accuracy.

Once a label is printed, it has to get from the machine to the product. That’s the job of the applicator, the mechanical arm that does the physical work. The choice of applicator is absolutely key, as it depends entirely on your product, your line speed, and the type of packaging you use.

After all, you wouldn’t handle a delicate box of glassware the same way you’d label a sturdy pallet. For anyone wanting to dig deeper into the different setups, exploring the range of advanced labeling systems is a great way to see how these components are tailored for specific jobs.

The applicator is where the system makes physical contact with your products. Choosing the right one is the difference between a smooth process and one plagued by damage or wonky labels.

There are several common applicator types, each designed for a different job on the production line. Let’s take a look at the most common ones.

Here’s a quick breakdown of the main applicator methods and where they shine.

| Applicator Type | Method of Application | Ideal For |

|---|---|---|

| Tamp-Blow | An arm extends towards the product, then a puff of air blows the label onto the surface. No direct contact is made. | Delicate items, or products with uneven or recessed surfaces where a gentle touch is required. |

| Direct Tamp | A pneumatic or electric arm extends and physically presses the label onto the product with a light, controlled touch. | Flat or slightly curved surfaces on stationary or slow-moving items like boxes and cases. |

| Wipe-On | The label is partially dispensed onto the leading edge of a moving product, then a roller smoothly ‘wipes’ it on. | High-speed lines with consistent product shapes, such as cartons moving quickly along a conveyor. |

| Corner-Wrap | A specialised arm applies the label across two adjacent sides of a box in a single, fluid motion. | Pallet and case labelling, where information needs to be seen from multiple angles. |

Getting this combination of print engine, controller, and applicator right is the key. When properly matched to your production line’s unique demands, your print and apply label system becomes an incredibly powerful and reliable asset.

To really get a feel for how these systems work in the real world, let’s follow a single package as it makes its way down a production line. This whole sequence is a blur of high-speed automation, happening in the blink of an eye to turn digital data into a physical, scannable label on your product.

Picture a box zipping along on a conveyor. As it nears the labelling station, its brief but important journey through the system starts. The process is all about precision and repeatability, built for incredible speed without ever compromising on accuracy.

First things first, the system needs to know a product has arrived. An optical sensor, basically a small electronic eye, is placed just before the applicator. As the box moves past and breaks the sensor’s light beam, it fires an instant signal to the system’s controller.

Think of this signal as the starting pistol. It tells the machine, “Right, a product is here and ready for its label.” This trigger is the key to synchronising every action perfectly with the product’s exact position on the conveyor.

Once it gets that signal, the controller immediately tells the print engine to get to work. The data for this specific label – maybe a unique barcode, a lot number, or a shipping address – is pulled in real-time from a connected database or a Warehouse Management System (WMS).

The print engine then whips up a high-resolution label with this precise information. This ability to print on demand is what makes these systems so important for any operation dealing with variable data. Every single package can get its own completely unique identifier.

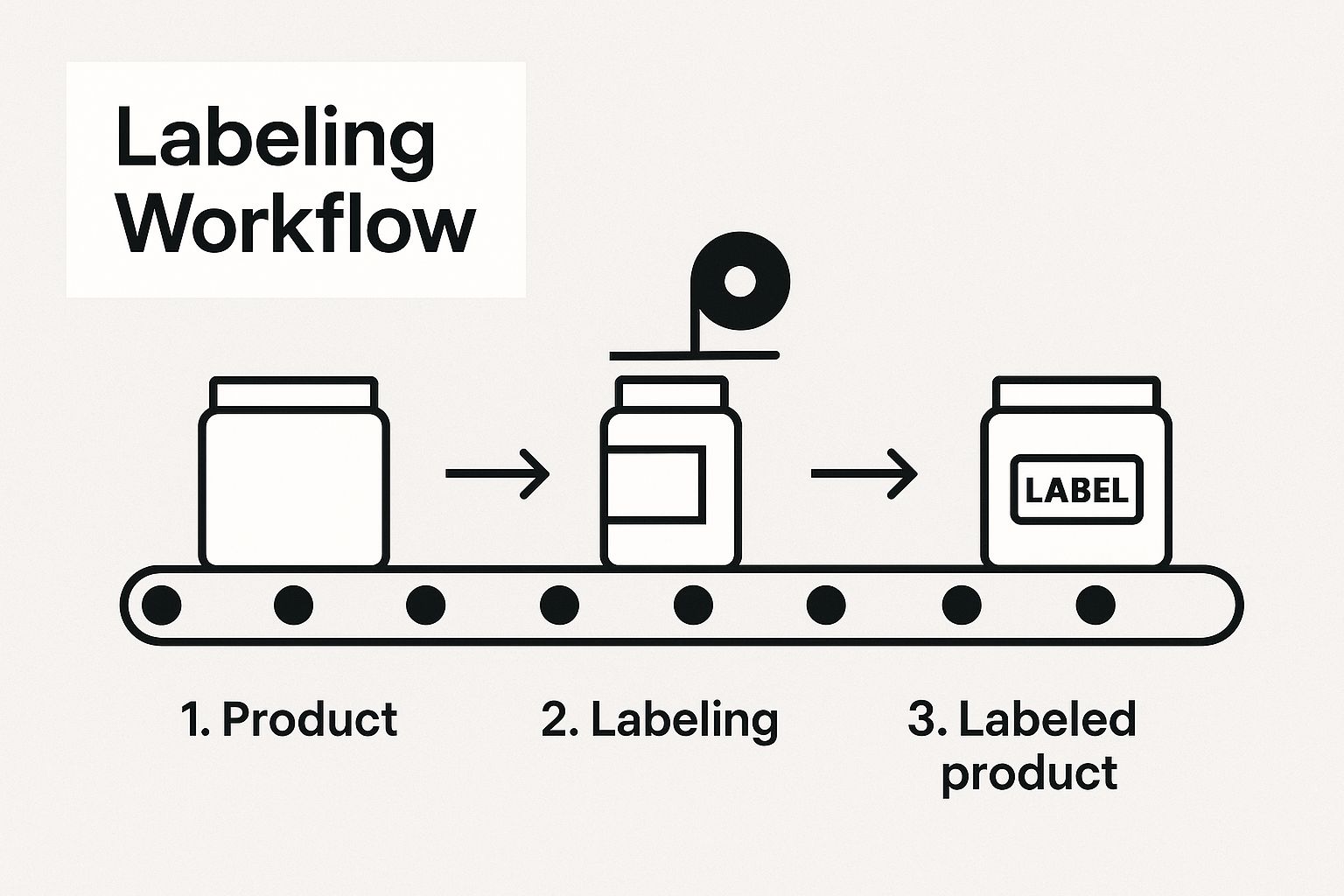

The image below shows how this workflow comes together.

As you can see, the product’s movement kicks off a perfectly timed sequence of printing and applying the label.

With the new label freshly printed and dispensed, the applicator arm springs into action. Depending on the setup, this might be a tamp, blow, or wipe-on applicator. The arm extends and places the label squarely onto the target spot on the box.

The entire movement is calibrated to the conveyor’s speed, ensuring the label goes on flat and smooth, without any creases, even on items moving at a serious pace. Once the job is done, the applicator retracts, already waiting for the next product.

The whole cycle, from that first sensor trigger to the final label being applied, often takes less than a second. This incredible speed means the print and apply system can easily keep up with even the fastest production lines, handling thousands of items an hour without missing a beat. The product then continues its journey, now correctly identified and traceable.

The real beauty of a print and apply label system is its adaptability. It’s not a one-size-fits-all solution; instead, it’s a versatile tool that solves critical, real-world problems for UK industries. These machines have become the quiet workhorses in countless fast-paced environments, from ensuring food safety to maintaining strict pharmaceutical compliance.

Their ability to print and apply variable data on the fly is what makes them so needed. In sectors where accuracy isn’t just a nice-to-have but a legal and moral requirement, these systems are indispensable.

This growing reliance on automation is a clear trend. The global market for this equipment was valued at around USD 4.65 billion and is expected to climb to USD 6.14 billion by 2031. This surge is all about the need for better product tracking and traceability, powered by on-demand, variable data printing. For a deeper look, this detailed report on print and apply labeling explores the global market trends.

In the food and beverage world, there’s no room for error. A simple mislabel can spiral into a costly product recall or, far worse, a public health incident. This is where print and apply systems prove their worth, applying key information with absolute precision.

When it comes to pharmaceuticals, labelling is all about patient safety and navigating a maze of regulations. The entire sector operates under incredibly tight controls, and print and apply label systems deliver the precision needed to stay compliant.

In this industry, these systems are much more than just label stickers. They are a fundamental part of a company’s quality control and regulatory program, applying unique serial numbers that guarantee every single item can be tracked from the production line right through to the patient.

This track-and-trace capability is a must-have for complying with rules like the Falsified Medicines Directive (FMD), which mandates unique identifiers on all prescription medicine packaging.

In the non-stop world of logistics, speed and clarity are the name of the game. A busy distribution centre is a river of constantly moving goods, and a single misplaced label can create a major bottleneck. Automated labellers are the engines that keep everything flowing smoothly.

They are constantly at work applying:

Putting a print and apply label system on your line isn’t just a simple equipment upgrade. It’s a strategic move that delivers real, measurable improvements straight to your bottom line. If you’re an operations manager or business owner, the benefits are tangible, solving some of the most stubborn headaches in production and logistics today.

The most immediate win is a massive jump in operational efficiency and throughput. These automated systems are relentless, working far faster than any person ever could, applying labels with perfect consistency hour after hour. This translates directly into more products processed, boosting your facility’s output without needing to hire more staff. The reduction in manual labour alone is a significant cost-saver.

Let’s be honest: manual labelling is a recipe for mistakes. A tired worker, a moment of distraction-it’s all it takes. A misplaced or incorrect label can snowball into rejected shipments, hefty retailer fines, or even a full-blown product recall. These are expensive, reputation-damaging problems.

Automation all but eradicates these risks. By pulling data directly from your management software, the system confirms the right information gets printed and applied every single time. This level of precision is your best defence against compliance issues and the costly rework that follows, protecting your margins from avoidable losses.

The accuracy of an automated system is its killer feature. It flips labelling from a potential point of failure into a reliable, consistent part of your quality assurance, drastically cutting the financial fallout from human error.

Clear, scannable barcodes are the lifeblood of any modern supply chain. A smudged, crooked, or low-quality barcode can throw a wrench in the works, causing inventory to go missing and shipments to be delayed. Print and apply systems confirm every single barcode is printed crisply and placed in the right spot.

This consistency delivers some powerful advantages:

To see how this fits into the grander scheme of things, it’s helpful to explore broader business process automation examples and see how different technologies slot together to create efficiency.

If you’re starting to see how this could work for you, a good next step is to understand the finer details of an automatic labeler machine. By strengthening this critical data link in your process, you’re not just applying labels-you’re building a more responsive and transparent supply chain.

Picking the perfect print and apply labeller isn’t a one-size-fits-all job. What works brilliantly for one production line could be a complete disaster on another. The secret is to match the technology to the reality of your factory floor, not the other way around.

Before you even think about talking to a supplier, you need to do a bit of homework. It all starts with asking some simple but key questions about how you operate day-to-day. Get this right, and you’ll find a system that slots right into your workflow, rather than forcing you to change everything.

Jotting down a few key details about your production line will give you a solid foundation for making the right choice. This isn’t just about technical specs; it’s about understanding the real-world demands you’re placing on the machine.

Think about these key factors:

Thinking about the quality of the individual components is just as important. It’s a principle that holds true even when selecting optimal label printing hardware for simpler tasks; the hardware must be fit for purpose.

A modern print and apply label system is much more than just a piece of machinery; it’s a smart, connected device on your network. How well it ‘talks’ to your other systems will make or break its usefulness.

You absolutely must check that it can integrate with your Warehouse Management System (WMS) or Enterprise Resource Planning (ERP) software. This is what allows you to pull in variable data on the fly, printing unique barcodes, batch codes, or shipping details for every single product. To get a better sense of how this works in practice, our guide on how to use a label application machine breaks down its role in a connected workflow.

Finally, don’t forget about the long game. Who are you buying from? A good supplier relationship is worth its weight in gold. You need to know that reliable support, routine maintenance, and easy access to spare parts are all part of the deal. It’s what keeps downtime to a minimum and protects your investment for years to come.

We get asked a lot of practical questions about how these systems work on a day-to-day basis. Here are a few of the most common ones.

Absolutely. One of the biggest strengths of a modern print and apply label system is its versatility. Most are engineered to work with a whole spectrum of label dimensions.

You can typically adjust the machine to manage different widths and lengths, which is a lifesaver when you’re dealing with varied product lines or packaging. This is a key point to thrash out with your supplier to make sure the machine you choose has the range you need.

This is a popular question, and the honest answer is: the speed varies. The specific model, the type of applicator arm it uses, and how much data needs to be printed on each label all play a part.

That said, you can find high-spec systems that will happily apply well over 100 labels per minute. They are more than capable of keeping up with even the most demanding production lines, whether that’s in a busy food and beverage plant or a high-volume logistics hub.

Like any key piece of kit, a little bit of routine care goes a long way. Regular maintenance usually involves simple tasks like cleaning the thermal printhead, wiping down the sensors to keep them accurate, and checking that all the moving parts of the applicator are free from debris.

Most suppliers will offer service contracts to handle the heavy lifting, which is a great way to keep your machinery in top form and avoid costly, unplanned downtime. If you’re curious about the technical principles that make all this work, we’ve got a great resource on the fundamentals of labelling science.

If you want expert advice on finding the perfect labelling solution for your production line, give us a shout. The team at Sessions UK can guide you to the right machine for your exact needs. You can find us at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.