What is a print label machine? It is a piece of kit designed to automatically print and stick labels onto products, packages, or containers. It works with incredible speed and precision, acting like a hyper-efficient member of your team who makes sure every single item gets the right branding and information, from barcodes to best-before dates.

Picture yourself hand-labelling hundreds, maybe thousands, of jars of honey for your growing food business. It would be painfully slow, you’d get crooked labels, and it would quickly become a massive bottleneck in your production. This is where a print label machine steps in. It takes that tedious, repetitive job and turns it into an automated part of your workflow.

But these machines aren’t just for huge factories. They come in all shapes and sizes, from small tabletop units perfect for a startup’s first batch runs, all the way to fully integrated systems built for high-speed, high-volume production lines. No matter the scale, the core purpose is the same: to deliver consistency and efficiency, two things any growing business desperately needs.

Bringing automation into your labelling process does so much more than just speed things up. It introduces a level of precision that a human simply can’t match over a long shift. Every label lands in the exact same spot on every product, giving your range a uniform, professional look that builds customer trust. This kind of accuracy is non-negotiable in industries like food, beverages, and pharmaceuticals, where regulations demand that information is clear and correctly placed.

Making the switch to an automated system brings some serious perks:

It’s no surprise that the demand for these machines is climbing. Here in the United Kingdom, the label printer market is set for steady growth. This is being fuelled by a real need for customised labels across all sorts of sectors, from retail and logistics to healthcare. Between new technologies, the boom in e-commerce, and ever-stricter labelling laws, businesses are being pushed to find smarter printing solutions. It’s a clear sign that automated labelling is no longer a luxury-it’s becoming standard practice. For a deeper look, you can explore the UK label printer market report to see these trends for yourself.

A print label machine is the bridge between a finished product and a market-ready one. It’s the final step that communicates brand identity, provides needed information, and protects consumer safety, all in a fraction of a second.

With this foundation, it’s easy to see why these machines are such a critical investment. They solve the everyday production headaches of speed, quality control, and efficiency, making them a cornerstone of any modern manufacturing or packaging operation.

Picking the right print label machine is a lot like choosing a vehicle for a business. A solo entrepreneur making local deliveries might just need a nimble scooter, whereas a national logistics firm needs an entire fleet of articulated lorries. The machine you choose has to be the right fit for your operational scale, production speed, and, of course, your budget.

No two labelling jobs are exactly the same, and the machinery available reflects that. The options range from simple handheld devices all the way up to complex, fully automated systems that run themselves. Figuring out where your business sits on that spectrum is the first step to making a smart investment.

For startups, artisan producers, or any business with smaller production runs, manual and semi-automatic machines offer the perfect blend of control and efficiency. Think of a local honey producer who needs to label a few hundred jars a week. Sticking each label on by hand is not only slow but often leads to wonky, unprofessional-looking results.

A manual label applicator is a straightforward handheld tool that helps place pre-printed labels cleanly and evenly. It’s a small step up that makes a big difference to the final look without a major financial outlay.

Take it one step further, and you have a semi-automatic machine. Here, an operator places the product-a bottle, jar, or box-into the machine, which then applies the label with mechanical precision. These systems are brilliant for operations that handle lots of different product shapes and sizes, as they can be adjusted in minutes. They represent a modest investment that delivers a huge improvement in professionalism over hand-labelling.

When your production volume starts climbing into the thousands per hour, any kind of manual handling becomes a serious bottleneck. This is where fully automatic inline systems really shine. These machines are the true workhorses of large-scale manufacturing, built for high-speed, continuous operation with minimal human input.

Picture a national beverage company bottling thousands of soft drinks every hour. A fully automatic print label machine slots directly into their conveyor belt system. It senses each bottle as it passes, prints the required information on the fly, and applies the label with pinpoint accuracy, every single time. These systems are built for endurance and can handle more complex jobs, like applying labels to both the front and back or adding tamper-evident seals.

While the initial cost is certainly higher, the return on investment comes from massive gains in output, lower labour costs, and rock-solid consistency. For any business aiming for mass-market distribution, a fully automatic solution isn’t just an option-it’s a competitive necessity. You can get a clearer idea of how different features affect equipment costs by exploring the key components of labelling machine prices.

See how manual, semi-automatic, and fully automatic print label machines stack up against each other to determine the best match for your business needs.

| Feature | Manual Machine | Semi-Automatic Machine | Fully Automatic Machine |

|---|---|---|---|

| Speed | Low | Moderate | Very High |

| Volume | Small batches | Small to medium batches | High-volume production |

| Consistency | Operator dependent | High | Extremely high |

| Flexibility | High (for different products) | High | Low (dedicated to one line) |

| Initial Cost | Very Low | Low to Moderate | High |

| Labour | High | Moderate | Very Low |

This table clearly shows the trade-offs involved. Your ideal choice hinges on finding the right balance between speed, cost, and the flexibility your operation requires.

The choice comes down to your unique situation. There is no single “best” machine-only the one that fits your current needs and future plans.

To help narrow it down, ask yourself a few key questions:

Choosing the right print label machine is about balancing today’s needs with tomorrow’s ambitions. A small-batch gin distillery has vastly different requirements from a pharmaceutical plant, and the right equipment reflects that reality. By carefully assessing your volume, budget, and growth trajectory, you can select a machine that becomes a true asset to your production line.

When you’re choosing a print label machine, it’s easy to get lost in the technical jargon. But moving past the broad categories and looking at the details is what makes the difference between a perfect fit and a constant headache. Getting these specifications right will give you the confidence to compare models and pick one that truly works for your business.

These aren’t just numbers on a spec sheet; they directly affect the quality of your labels, the pace of your production line, and how smoothly your whole operation runs. Let’s break down the features that really matter.

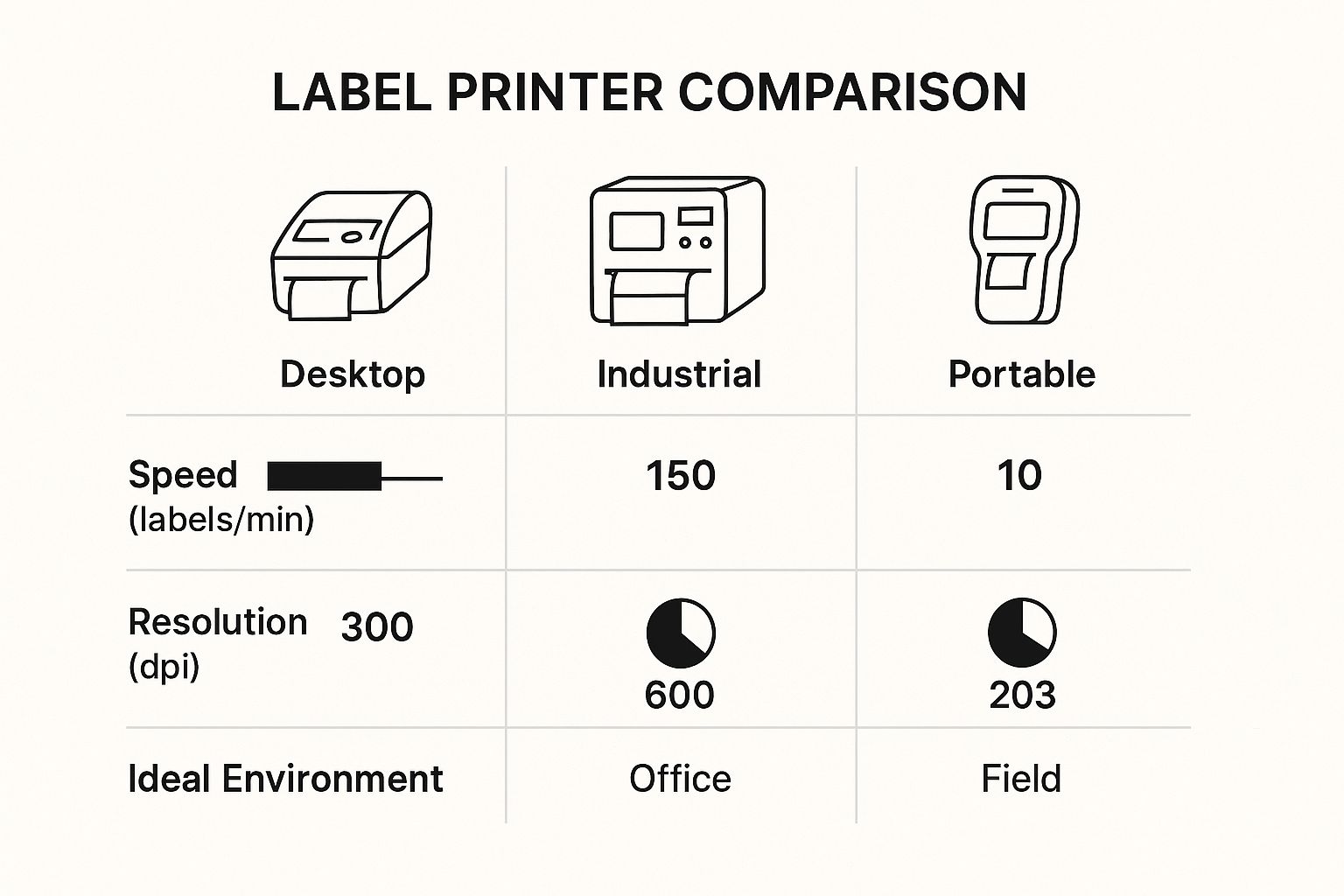

Print resolution is measured in dots per inch (DPI), and it’s all about the sharpness of your final label. Think of it like a TV screen – the more pixels (or dots), the crisper and more detailed the picture. A low-resolution printer might be okay for simple, large text, but it’ll make a mess of small fonts or intricate graphics.

For most day-to-day labelling, 203 DPI gets the job done. But if your labels feature complex barcodes, QR codes, or very fine print, you’ll need to step it up.

The scannability of a barcode is directly tied to its print quality. A fuzzy, poorly printed barcode can cause chaos in your logistics and frustration at the checkout. Investing in the right DPI from the start is an investment in a smoother operation.

Printing speed is usually measured in millimetres per second (mm/s) or sometimes in labels per minute. In simple terms, this tells you how fast the machine can churn out labels. For any high-volume operation, this is absolutely critical. A machine that’s too slow will create a bottleneck, holding back your entire production line.

Don’t just think about your average day; consider your peak production times. A machine that seems fast enough in March might not keep up with the Christmas rush. A food producer, for example, will need a machine that can handle huge volumes in the run-up to seasonal peaks. To get a better feel for this, understanding the specific needs of a label printer machine for food can offer some really useful insights.

A brilliant print label machine is useless if it doesn’t fit into your existing workflow. First, check the maximum and minimum label widths it can handle. You need to be sure it accommodates not just your current label designs but also any you might need in the future. A bit of versatility here can save you buying a whole new machine down the line.

Connectivity is the other piece of the puzzle. How are you going to send print jobs to it?

You’ll come across two main printing technologies. Each one has its own strengths, and the right choice depends entirely on how long your labels need to last and what kind of environment they’ll be in.

Direct Thermal Printing

This clever method uses special heat-sensitive paper. The printhead applies heat directly to the paper, which darkens to create the image. The big advantage? No ink, toner, or ribbons are needed. This keeps running costs down and makes operation simple. The catch is that the labels are sensitive to light and heat, so they can fade over time. This makes them ideal for short-term uses, like shipping labels or receipts.

Thermal Transfer Printing

This technique is a bit different. It uses a heated printhead to melt a wax or resin ribbon onto the label material. The result is a tough, durable image that stands up to fading, moisture, and general wear and tear. It’s the go-to choice for product identification, asset tracking, and any label that needs to survive in tougher conditions.

A print label machine isn’t just another piece of equipment; for many businesses, it’s the unsung hero of their daily operations. From the food on our tables to the medicines in our cabinets, these machines work tirelessly behind the scenes to guarantee safety, efficiency, and brand consistency. Their roles are incredibly diverse, solving unique challenges specific to each sector.

You really start to appreciate the value of these machines when you see them in action. They aren’t one-size-fits-all solutions. Instead, they are finely tuned to meet precise industry demands. By looking at how they’re used in different fields, we can see just how versatile and needed they are in modern commerce.

In the fiercely competitive food and beverage world, a label has to wear many hats. It’s the product’s identity, carrying the brand’s logo and eye-catching design. It’s also a legal document, displaying nutritional information, allergen warnings, and expiry dates as required by law. A print label machine automates this entire, critical process with flawless consistency.

Picture a craft brewery bottling a new seasonal ale. A specialised bottle labeller can apply front and back labels to thousands of cylindrical containers every hour, each one perfectly aligned. Or think of an artisanal cheesemaker, where a semi-automatic machine might apply labels to irregularly shaped packages, giving them a professional finish that would be impossible to achieve by hand.

These machines are built to handle materials designed to withstand condensation and refrigeration, making sure the label remains intact and readable from the production line all the way to the customer’s fridge. You can explore how these machines boost output by reading our guide on enhancing productivity in manufacturing.

For the logistics and warehousing industry, labelling is the language of efficiency. Every single box, pallet, and package needs a clear identity to be tracked through a complex, fast-moving supply chain. A print label machine is the engine that drives this system, churning out the barcodes, shipping addresses, and tracking numbers that keep goods moving.

Step inside a busy distribution centre, and you’ll see industrial-grade machines printing hundreds of shipping labels every minute. These are then automatically applied to packages whizzing by on a conveyor belt, ready for sorting and dispatch. This level of automation drastically cuts down on human error, preventing the costly mis-shipments that waste both time and money.

The accuracy of a single barcode label can determine whether a package reaches its destination on time or gets lost in the system. In logistics, precise labelling isn’t just a detail-it’s the foundation of the entire operation.

The global market for label printers clearly reflects this heavy industrial reliance. The market is projected to grow from USD 553.9 million in 2025 to USD 836.4 million by 2035. The industrial segment alone makes up about 50% of this market, showing just how critical these machines are. You can learn more by reading the full research about the label printer market growth.

Nowhere is labelling more critical than in the pharmaceutical industry. Here, a mistake isn’t just an inconvenience; it can have serious health consequences. Accuracy, compliance, and traceability are non-negotiable, and specialised pharmaceutical-grade labellers are built to meet these exacting standards.

These machines handle a variety of intricate tasks with incredible precision:

A typical application might involve a machine that applies a wrap-around label to a medicine bottle, prints a unique batch code and expiry date, and then verifies the print quality with a built-in vision system. If any label fails the check, it’s automatically rejected from the production line. This closed-loop quality control is a must in such a highly regulated environment, making sure every product is safe, compliant, and fully traceable from the factory to the pharmacy shelf.

Think of your print label machine like a workhorse. Look after it, and it will reliably churn out quality labels day in, day out. A little bit of regular care is all it takes to protect your investment, avoid frustrating downtime, and keep the whole production line humming along.

If you let things slide, you’re just asking for trouble. Dust, sticky adhesive residue, and tiny bits of label backing are the usual suspects. They’re the reason behind fuzzy prints, constant label jams, and unnecessary wear and tear on important parts. A few minutes of simple cleaning can honestly save you hours of headaches later.

The easiest way to keep your labeller happy is with a consistent cleaning schedule. You just need to focus on the parts that are in the thick of the action-the ones that get covered in dust and adhesive.

Here’s a straightforward routine that works every time:

Don’t think of cleaning as a chore. It’s more like a quick health check for your machine. A couple of minutes wiping down the printhead and roller can prevent the major pain of a misprinted batch or a sudden production stop.

The quality of the labels and ribbons you feed into your machine makes a huge difference. It can be tempting to save a few quid on cheaper, third-party supplies, but sticking with manufacturer-approved materials is the smarter play in the long run. They’re designed to work perfectly with your machine’s specific heat settings and mechanics.

Using the wrong stuff can cause real problems. Poor-quality adhesives can leave a sticky mess all over the platen roller and printhead, which leads to jams and shoddy prints. The wrong kind of ribbon might force you to crank up the heat, drastically shortening the life of your expensive printhead. For a deeper look, our guide to the regular maintenance of labelling machines has some great pointers.

Even a perfectly maintained machine can have an off day. Knowing how to spot and fix the simple stuff will get you back on track in no time.

Prints look faded or patchy?

Machine skipping labels?

The world of labelling is moving well beyond simple barcodes and expiry dates. The print label machine of tomorrow is already taking shape, becoming smarter, more sustainable, and deeply connected to the wider production line. Getting to grips with these changes is helpful if you want to invest in a machine that won’t just work for you today but will keep you competitive for years to come.

These aren’t far-off concepts from a sci-fi film; they are practical shifts already reshaping how businesses track products, talk to customers, and manage their environmental footprint. From labels that chat with your stock system to materials that simply melt away in a compost bin, the future is arriving fast.

One of the biggest leaps forward is the move to smart labels. Think of them less as printed stickers and more as interactive tools. By embedding technologies like Radio-Frequency Identification (RFID) and Near-Field Communication (NFC) tags, a humble label effectively becomes a digital passport for your product.

Imagine doing a full warehouse stocktake in minutes, without scanning a single barcode. That’s what RFID can do. For your customer, an NFC-enabled label on a bottle of wine could offer food pairing suggestions or the story of the vineyard with a simple tap of their smartphone.

This technology opens up a world of possibilities:

Being environmentally responsible is no longer a “nice-to-have”; it’s a core expectation from customers and regulators alike. The labelling industry is responding with a wave of new materials and machine designs that put sustainability first. The print label machine is being redesigned from the ground up to handle these eco-friendly alternatives without skipping a beat.

We’re seeing huge demand for machines that can work with compostable films, recycled papers, and plant-based adhesives. Another big development is linerless labelling. This brilliant innovation does away with the slick backing paper that usually goes straight to landfill, cutting waste by up to 40% and fitting more labels onto every roll.

The UK’s sustainable labels market is forecast to reach £18 billion by 2025, driven by tougher regulations and consumer demand for greener products. This rapid growth shows a permanent shift in the industry. You can learn more about the trends shaping the future of labelling technology.

Artificial Intelligence (AI) is also leaving the server room and heading for the production floor. In the latest labelling systems, AI is making operations more efficient and incredibly reliable. It’s like having a hyper-vigilant supervisor on duty 24/7, constantly monitoring performance and flagging potential problems before they can cause a shutdown.

AI-powered systems can analyse machine data to predict when maintenance is needed, pinging your team with an alert before a part fails. They can also run automated quality checks using built-in vision systems, spotting and rejecting misaligned or poorly printed labels on the fly. This slashes waste, reduces the need for manual inspection, and guarantees every product leaving your facility looks perfect.

Stepping into the world of labelling equipment can feel a bit overwhelming, so it’s natural to have a few questions. We’ve put together some straightforward answers to the queries we hear most often, helping you make a more confident choice for your business.

Think of direct thermal printing like a supermarket receipt. It uses special, heat-sensitive paper that turns black when the printhead heats it. There’s no ink or ribbon involved, which keeps things simple and affordable for things that don’t need to last forever, like shipping labels or event tickets. The catch? The print can fade over time, especially if it’s exposed to sunlight or heat.

Thermal transfer, in contrast, is built for endurance. It uses a heated printhead to melt a wax or resin ribbon directly onto the label itself. This creates a crisp, incredibly durable print that stands up to moisture, abrasion, and fading. It’s the go-to method for product labels, asset tags, and anything else that needs to stay readable for years to come.

Choosing the right label material really boils down to two things: where your product will live and how long the label needs to stick around.

Don’t forget to think about the surface you’re labelling. A smooth glass jar has very different needs from a textured cardboard box or a squeezable plastic bottle. You also need to decide if you want the label to be permanent or easily removable. Getting this right is key to a professional finish.

Absolutely. Most modern print label machines are designed with flexibility in mind and can handle a variety of label dimensions. You’ll always find the minimum and maximum supported label widths listed in the machine’s technical specs. This adaptability is great because it means a single machine can often serve several different product lines.

If your production runs involve frequent changes between very different label sizes, look for a model designed for quick changeovers. Machines with tool-free adjustments for the label guides are a massive time-saver, helping you minimise downtime and keep everything running like clockwork.

Ready to find the perfect labelling solution for your business? The experts at Sessions UK are here to help. Explore our full range of labelling machinery and find the right fit for your production needs. Visit us at https://sessionsuk.com to get started.

Copyright © 2025 Sessions Label Solutions Ltd.