A printing labels machine automates the final step of your production process-applying labels to your products. These are not one-size-fits-all bits of kit; they can be anything from a simple manual applicator for a small workshop to a fully automatic machine that's an integral part of a high-speed production line. For any business that wants to look professional and work efficiently, they are a key piece of equipment.

Choosing the right label machine is not about finding the one with the most bells and whistles. It is about taking a good, hard look at your own operations and finding a machine that fits perfectly. Get this wrong, and you have a very expensive paperweight. Get it right, and you unlock a new level of efficiency.

It’s a big decision. The UK printing services industry, which these machines are a part of, is worth an estimated £9.0 billion. You can dig deeper into the UK label printing market over at plimsoll.co.uk.

Your specific needs should always be the starting point. A small artisan gin distillery has completely different labelling challenges than a massive pharmaceutical plant. Let’s break down how to figure out what you really need.

How many labels are you actually applying? Knowing your daily or weekly volume is the single most important factor. This number will immediately point you towards the right category of machine.

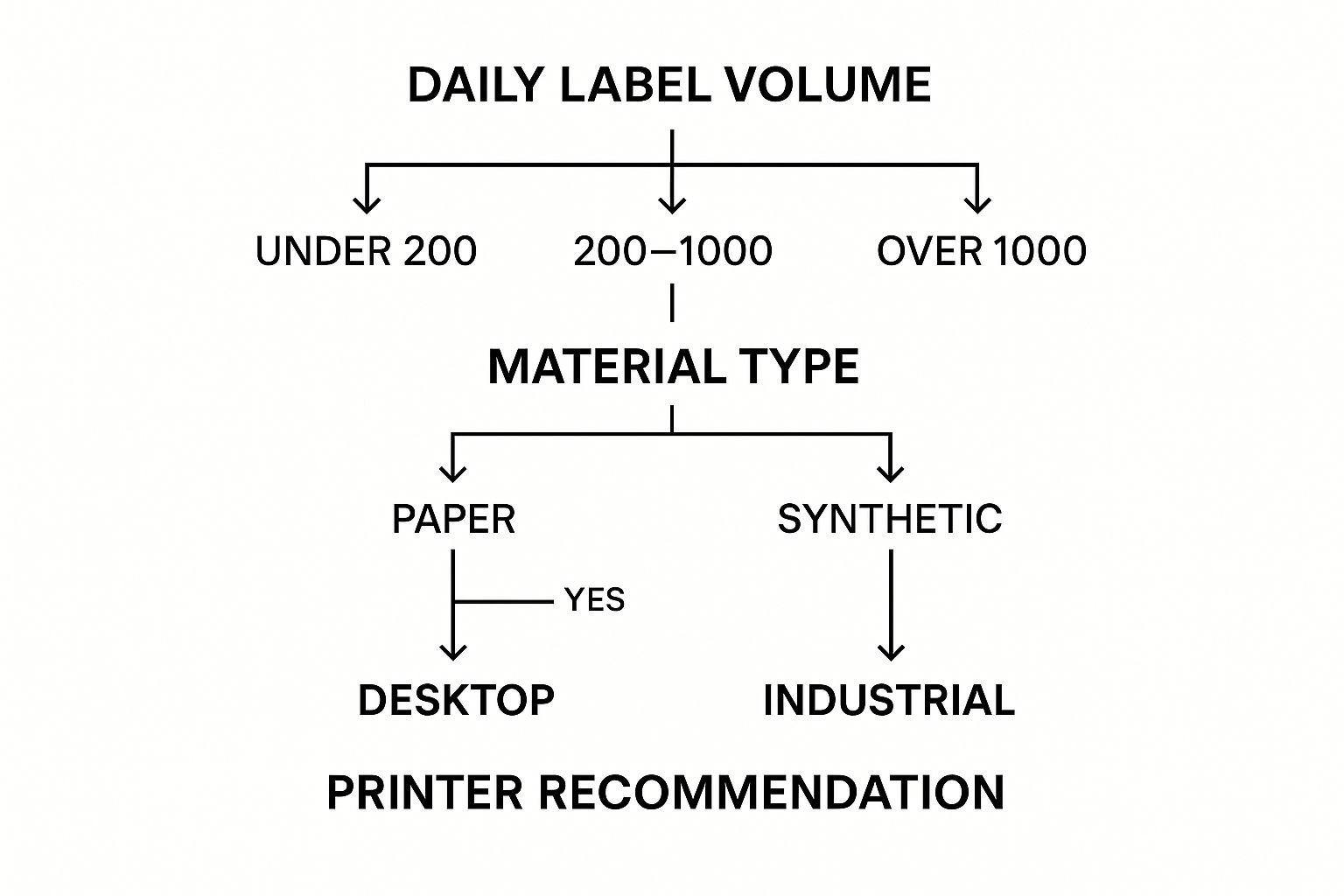

This handy chart gives a visual guide to help you make a quick decision based on how much you produce.

As you can see, the path from your daily output to the right machine type is fairly clear. Of course, there are always other factors to consider when operating an automatic label machine that go beyond just volume.

A classic mistake I see all the time is businesses buying a machine that only just covers their current needs. You should always be thinking about where you’ll be in the next 1-2 years. Buy for the business you're growing into, not just the one you have today.

To make this even simpler, I have put together a quick-reference table. Use it to get a feel for which machine type aligns with your business scale and what you're labelling.

| Business Scale | Typical Application | Recommended Machine Type |

|---|---|---|

| Start-up / Small Business | Artisan food jars, cosmetic bottles, craft beer cans | Manual or Semi-Automatic Desktop Machine |

| Growing / Medium Business | Higher volume e-commerce shipping, consistent product runs | Robust Semi-Automatic or Entry-Level Automatic Machine |

| Large-Scale Enterprise | Fast-moving consumer goods, pharmaceutical packaging | Fully Automatic, High-Speed In-line System |

This table should give you a solid starting point. From here, you can dig into the finer details of each machine type, knowing you're already looking in the right place.

It sounds obvious, but you’d be surprised how often it’s overlooked: the shape, size, and material of your products will absolutely dictate the kind of printing label machine you need. I have seen it time and time again-a machine that's perfect for flat boxes ends up creating a mess of wrinkled, wonky labels on tapered tubs. This kind of mistake doesn't just look unprofessional; it actively undermines your brand's image.

Getting the technical specs right from the start is non-negotiable. For instance, a microbrewery labelling thousands of glass bottles needs a reliable wrap-around system that handles curved surfaces without a hitch. A cosmetics brand with small, tapered pots faces a completely different challenge. They will need a machine with finely adjustable guides to manage that tricky shape and prevent the dreaded label creasing.

The applicator is the business end of the machine-it’s what physically sticks the label to your product. If you get this part wrong, nothing else matters. It's probably the number one cause of poor labelling I see in the field.

Different shapes demand different tools for the job:

Here's a piece of hard-won advice: versatility is your friend. If your product line includes both round bottles and flat-topped tins, look for a machine with interchangeable applicator heads. That flexibility can save you from having to buy, house, and maintain two separate machines down the line.

Don't forget about the labels themselves. The machine’s internal mechanics, like tension controls and the print head, have to play nicely with the media you're using, whether that’s standard paper, tough vinyl, or a clear film.

Glossy vinyl labels, for example, are thicker and need different roller pressure than their paper counterparts. Those transparent ‘no-label look’ films are notoriously tricky, demanding incredibly precise tension to avoid bubbles and wrinkles.

Some industries have very specific requirements. For instance, the world of label printing for clothing has its own set of rules and material needs. Always dig into a machine's spec sheet to confirm which label materials and thicknesses it can handle before you even think about making a purchase.

Choosing the right level of automation for your label applicator isn't just about what you need today; it's about where you're headed. This is a big decision that balances your current output, budget, and future ambitions. Get it right, and labelling becomes a smooth, integrated part of your workflow. Get it wrong, and you’ve just created your next production bottleneck.

For a small-scale operation, maybe a craft brewery or an artisan food business producing a few hundred items a week, a manual or semi-automatic machine is often the perfect fit. It gives you a consistent, professional finish that hand-labelling can't touch, but without the hefty price tag of a fully automated system. Think of it as your first major step towards serious production.

But what happens when you start scaling up? A business pushing out thousands of units a day will quickly get bogged down by anything less than a high-speed solution. This is where semi-automatic and fully automatic systems really shine. They're built for volume and reliability, handling large batches with minimal human intervention.

To avoid outgrowing your investment in a year, you need to look ahead. Start by calculating your current weekly output. Then, realistically project your production goals for the next 18-24 months. This simple forecast is your best tool for choosing a machine that can scale with you, saving you from a costly and disruptive upgrade down the road.

The market reflects this need for speed and efficiency. The global label printer market is forecast to jump from USD 553.9 million in 2025 to USD 836.4 million by 2035. Industrial-grade printers are expected to command roughly 50% of that market. This tells us that serious businesses are investing in serious equipment.

It's easy to focus on the initial purchase price, but the real win is in the long-term savings. A fully automatic machine costs more upfront, but the reduced labour hours and increased throughput often deliver a much stronger return on investment over the machine's life.

Thinking about a new labeller is the perfect time to review your wider manufacturing flow. Understanding the principles of optimizing production processes can give you a clearer perspective on how this one piece of equipment impacts your entire operation. It helps you make a smarter choice that benefits the whole line, not just one station.

Staying on the right side of UK regulations isn't just good practice; it's a fundamental part of running a business. Your choice of label printer plays a surprisingly big role here, especially if you're in a heavily regulated industry. A machine that delivers precision isn't a luxury-it's your first line of defence against non-compliance.

Think about the food and beverage sector, where allergens and nutritional information must be perfectly clear. Or the chemical industry, bound by strict CLP regulations demanding specific hazard symbols and warning phrases. Your printer has to get these details right every single time, or you could face serious legal trouble. It's that simple.

Beyond today's compliance rules, the future of labelling is already taking shape. We're seeing a big shift towards smart labels that use NFC (Near Field Communication) and RFID (Radio-Frequency Identification). These are not just fancy barcodes; they create a direct, interactive link between your product and the customer.

Choosing a machine that can already handle RFID or NFC encoding isn't just about future-proofing. It's about unlocking real, practical benefits for your business right now.

Here’s what that looks like in practice:

Investing in a machine with smart label capabilities might feel like a big step, but it’s one of the smartest moves you can make. It sets you up for future regulations while giving you powerful new tools to manage stock and engage with your customers. It's an investment that pays you back.

When your new printing label machine finally arrives, the temptation is to get it running immediately. But taking the time to set it up properly is the bedrock of reliable performance. Rushing this stage is a recipe for frustration, often leading to skewed labels or poor adhesion-problems that are entirely avoidable.

Start by unboxing and positioning the machine with plenty of room to work. Then, it's time to load your labels. Get the roll seated correctly on the spindle and double-check that the entire media path is clear. You will need to adjust the guides to match the width of your label's backing paper. They should be snug enough to prevent movement, but not so tight they constrict the material.

A classic rookie mistake is cranking the label guides too tight. This can make the label stock buckle or feed at an angle, which is a guaranteed way to get crooked labels. The goal is for the material to glide through smoothly with just a tiny bit of wiggle room.

Next up is calibration. This is where you teach the machine to see the gap between one label and the next. Most modern labellers have an auto-calibrate function, which makes this easy. Get into the habit of running it every single time you load a new roll, because even tiny variations between batches can throw off the accuracy.

With the machine calibrated, you're ready to run a few test products. Watch the label placement like a hawk. You will likely need to make small, gradual adjustments to the applicator head or product guides. Keep tweaking until the label lands exactly where you want it, every single time. This initial fine-tuning is what makes labelling machines enhancing productivity in manufacturing a reality, not just a concept.

To get the most out of your investment and dodge surprise downtime, a simple and consistent maintenance routine is your best friend. It doesn't have to be complicated. Just create a schedule for a few basic checks.

Investing in new equipment always brings up questions. A label printing machine is a big commitment, and you want to be sure you're making the right choice for your business. Let's walk through some of the queries we hear most often from people just like you.

This is easily the most frequent question we get, and it’s a critical one. The two technologies look similar but are worlds apart in terms of durability. The right choice really boils down to how long your label needs to last.

Direct Thermal printers use a special heat-sensitive paper. The print head applies heat directly to the paper, causing it to darken and form the image. There’s no ink, toner, or ribbon involved, which makes it a very budget-friendly option for things that don't need a long shelf life. Think shipping labels, receipts, or food-to-go stickers. The major drawback? The print will fade over time, especially if it’s exposed to sunlight or heat.

Thermal Transfer works differently. It uses a heated print head to melt a ribbon onto the label’s surface. This process creates a crisp, durable, and long-lasting print that’s resistant to fading, smudging, and chemicals. If you need a label to stay readable for years-for product branding, asset tracking, or compliance information-this is absolutely the way to go.

For the most part, yes. Modern semi-automatic and automatic labellers are designed for versatility. They typically come with adjustable guides and sensors that you can set to handle a variety of label dimensions and container shapes.

Here’s a bit of hard-won advice: always check the machine’s specification sheet before you buy. It will clearly list the minimum and maximum container diameters and label sizes it supports. This one simple check can save you from the major headache of buying a machine that can’t handle your full product range.

That said, if you’re dealing with extreme size differences-say, switching from tiny 10ml vials to large packing boxes-you’ll almost certainly need separate machines or at least different applicator heads.

If you need some expert advice on finding the perfect machine for your products, the team at Sessions UK is here to help. You can also explore our full range of professional labelling machines on our website.

Copyright © 2025 Sessions Label Solutions Ltd.