In the highly regulated food and beverage industry, accuracy and hygiene are paramount. Our labelling machines for food are specifically designed to meet the sector’s stringent demands for safety, compliance, and efficiency. From ensuring allergen information is clear and correct to applying use-by dates with perfect precision, the right machine is a critical asset. As a leading supplier of food labelling machines UK, Sessions UK provides robust, wash-down-ready systems that integrate seamlessly into your production environment, whether you are packaging products in jars, cans, boxes, or flexible pouches.

Flat products - Label on top or side

Output - up to 100 labels per minute

Range - 20 to 230mm wide labels

Operation - Automatic

Flat bottles or cartons

Output - 20 per minute

Range - 20 to 250mm

Operation - Semi auto / product switch

Flat products

Output - up to 60 per minute

Range - 20 to 160mm wide label

Operation - Automatic

Print and wrap round

Output - up to 20 per minute

Range - 20 to 100mm diameter

Operation - Semi auto / product switch

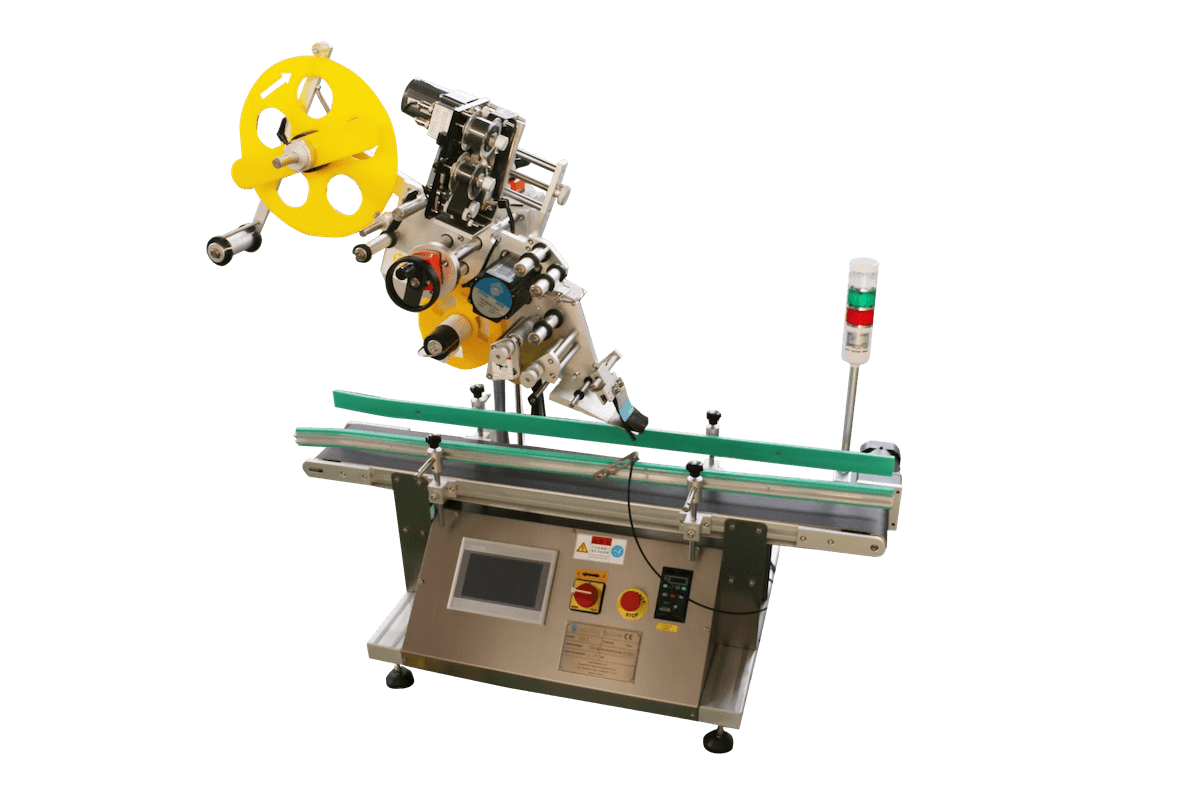

Flat Products

Output - up to 50 per minute

Range - 20 to 80mm wide

Operation - Semi auto / belt conveyor

Flat products

Output - up to 100 labels per minute

Range - 20 to 160mm wide label

Operation - Automatic

Flat products

Output - up to 100 labels per minute

Range - 20 to 190mm wide labels

Operation - Automatic

Front & Back

Output - up to 100 per minute

Range - 20 to 195mm high labels

Operation - Automatic / Slat Conveyor

Wrap round

Output - up to 150 per minute

Range - 20 to 100mm wide products

Operation - Automatic / slat conveyor

Wrap round

Output - up to 100 per minute

Range - 20 to 100mm diameter

Operation - Automatic / slat conveyor

Wrap round

Output - up to 10 per minute

Range - 20 to 100mm diameter

Operation - Manual / handle

Wrap round

Output - up to 25 per minute

Range - 12 to 250mm diameter

Operation - Semi auto / footswitch

Widths - 6, 10 and 16"

Setup Guide Included

Flat products

Output - up to 30 per minute

Range - 20 to 100mm label size

Operation - Semi auto / footswitch

Standard labelling equipment is often unsuitable for the unique challenges of a food production environment. Food labelling machines are engineered with specific features to handle hygiene requirements, complex regulations, and demanding physical conditions.

Food processing areas require frequent and thorough cleaning. Our machines are built using food-grade materials, primarily Grade 304 or 316 stainless steel, to prevent corrosion and contamination. Many models carry an IP65 rating, meaning they are protected against dust ingress and low-pressure water jets from any direction. This robust construction ensures the equipment can withstand rigorous daily wash-down routines without compromising its electronic components or operational integrity.

Food labelling regulations are strict and constantly evolving. Information regarding ingredients, nutritional values, allergens (e.g., Natasha’s Law), and origin must be displayed accurately. Furthermore, traceability through batch codes and dates is essential for quality control and recalls. Our systems, particularly print-and-apply models, ensure this variable data is printed clearly and applied correctly, providing a reliable audit trail for every product that leaves your facility.

Food production facilities can be demanding places for machinery. Environments can be wet from cleaning, cold in refrigerated or frozen food areas, or hot and steamy near ovens and filling stations. Our labelling machines for food are built to perform reliably in these conditions, ensuring consistent uptime and preventing costly production delays.

We offer a versatile range of machines designed to handle the diverse packaging formats used in the food industry.

Glass jars and bottles are standard for products like sauces, jams, preserves, and beverages. Our jar labelling machines are designed for high-accuracy wrap-around or front-and-back application, ensuring a premium look on the shelf. These machines can be integrated into filling and capping lines to create a fully automated process. For more details on these systems, see our dedicated page on bottle labelling machines.

Canning lines for products like soup, vegetables, and fish operate at very high speeds. Our can labelling machines are engineered for this demanding application, using robust wrap-around systems that can keep pace with outputs of several hundred cans per minute. They ensure labels are applied smoothly to metal containers without skewing or creasing.

For products packaged in cardboard, from ready meal sleeves to cereal boxes, our box labelling machines offer flexible solutions. Top and bottom labellers can apply promotional or informational labels to sealed cartons. We also provide systems that apply labels to flat-packed sleeves before they are erected, a common method for achieving high speeds and accuracy in ready meal production.

Labelling flexible packaging like stand-up pouches and bags presents a unique challenge. We offer solutions that can apply labels to flat pouches before they are filled or systems that use specialised conveyors to handle filled, unstable packs, ensuring the label is applied smoothly on the desired panel.

The high-volume nature of the food industry means that automation is key to profitability and efficiency.

Nearly all large-scale food producers rely on fully automatic labelling machines. These are integrated directly into the production line, providing a hands-free process that minimises labour costs and maximises throughput.

In the world of Fast-Moving Consumer Goods (FMCG), speed is everything. Our high speed labelling machines are engineered with servo-driven technology to meet the extreme demands of modern food production lines, ensuring label application keeps pace with even the fastest fillers and packaging equipment.

For fresh products with a short shelf life, such as sandwiches, baked goods, and pre-packaged meat, print-and-apply systems are essential. They print variable data like “packed on” and “use by” dates, prices, and weights in real-time before applying the label.

While packaging is a key factor, the product itself can influence the choice of machine. We have extensive experience in providing dedicated labelling machines for food products, including dairy items, ready meals, baked goods, coffee, and more.

Selecting a supplier with proven experience in the food industry is vital. Sessions UK understands the specific challenges you face, from hygiene audits to achieving OEE (Overall Equipment Effectiveness) targets. We provide robust and reliable food labelling machines uk businesses can depend on. Our range of industrial labelling systems are built for the rigours of 24/7 food production. As a leading UK provider of Labelling Machines, our team offers expert consultation to ensure you get a system that is fit for purpose, compliant, and delivers a strong return on investment.

Can your machines operate in a wet or refrigerated environment? Yes. Many of our food labelling machines are available with an IP65 wash-down rating and are constructed from stainless steel, making them suitable for wet environments. They can also be configured to operate reliably in cold, refrigerated conditions.

How do your machines help with allergen labelling? Our machines apply pre-printed labels with extreme accuracy, ensuring allergen boxes are always legible. When combined with a thermal transfer printer, our print-and-apply systems can print variable allergen information driven by a database, reducing the risk of human error.

What information do you need for a quote? Please provide samples or drawings of your packaging, details of the label(s), your required line speed (products per minute), and a description of the production environment (e.g., wet, dry, ambient, chilled).

Can you label products that are hot-filled or frozen? Yes. This is often an adhesive challenge rather than a machine one. We work with you and our label partners to specify the correct adhesive for your application, and our machines can be configured to apply labels to hot, cold, or frozen surfaces.

Ensure your food products are labelled safely, accurately, and efficiently. Contact the Sessions UK team today to discuss your specific application. Our experts are ready to help you find the perfect labelling solution for your production line.

Copyright © 2026 Sessions Label Solutions Ltd.