An RFID clothing tag is a smart label. It’s a small digital tag attached to a garment that uses radio waves to broadcast information, giving every single item its own unique ID. This allows for incredibly fast and accurate tracking from the factory to the shop floor, without needing a direct line of sight.

Think about the standard barcode on a t-shirt. To scan it, you have to find it and point your scanner directly at it. One by one. Now, picture being able to count every single t-shirt in a stockroom in seconds, even the ones still packed in boxes, just by waving a scanner in the general direction. That’s the leap forward an RFID tag provides.

At its core, the technology is a simple form of wireless communication. Each tag acts like a unique digital passport for a piece of clothing, enabling item-level tracking on a scale that barcodes just can’t handle. This whole concept is built on three main components working in harmony.

An RFID system is more than just the tag you see on the garment. For it to work, it relies on a trio of interconnected parts, with each playing a specific role in capturing and processing the data.

Together, these three elements create a complete, live picture of where every tagged item is at any moment. You need all three for the system to deliver the kind of real-time visibility that makes it so powerful for retail.

As you look into RFID, you’ll come across a few different types, but one completely dominates the apparel industry: Passive UHF (Ultra-High Frequency). Understanding why this specific type has become the standard clarifies how the system works in a busy shop.

The combination of a low-cost, battery-free design and a long-range reading capability makes passive UHF the go-to choice for fashion retail. It perfectly balances performance with the practical need to tag a high volume of products economically.

This choice of technology isn’t an accident; it’s a solution tailored to the demands of the fast-paced fashion world. The ability to perform a stock take quickly and accurately without manual, item-by-item counting is a major reason so many businesses are making the switch.

If you’re looking for more background on the general principles, you can learn more about what RFID labels are and how they function across different industries at https://sessionsuk.com/what-are-rfid-labels/. Grasping these fundamentals is key to seeing the bigger picture before we look at the business benefits.

Bringing RFID tags into your fashion business is like switching from a blurry photograph to a high-definition image. You’re moving away from guesswork and into a world of precision. The technology tackles some of the industry’s oldest and most frustrating operational problems, focusing on two key areas: getting your stock count almost perfect and seriously cutting down on theft.

But these aren’t just back-office tweaks. The improvements ripple out to the customer. When you know exactly what you have and where it is, you can serve people better, whether they’re on the shop floor or browsing your website. It creates a tighter, more reliable operation from the stockroom right up to the till.

Let’s be honest, traditional stock-taking is a nightmare. It’s slow, needs a whole team, and is riddled with human error. Scanning barcodes means handling every single item one by one, a painstaking process that can take days and often only gets you to about 65-75% accuracy. An RFID clothing tag system blows this old method out of the water.

With RFID, a stock count that used to tie up a team for a whole weekend can be done in a few hours by one person with a handheld scanner. Because each tag has its own unique ID and can be read from a distance, you can scan hundreds of items a second without even opening the boxes. This isn’t just a small improvement; it pushes your inventory accuracy up to 98% or even higher.

This leap in accuracy changes everything. It means the numbers in your system are a true reflection of what’s on the shelves, getting rid of the guesswork that leads to expensive mistakes.

When you know precisely what you have, you avoid two of the biggest retail headaches: stockouts and overstock. A stockout is a lost sale and a let-down for the customer. Overstock ties up your cash in clothes that aren’t selling and will probably need a heavy discount to shift later. Real-time accuracy helps you find that sweet spot, keeping popular items available while making sure you’re not drowning in unwanted inventory. For more on this, it’s worth exploring labelling options for production teams.

Retail theft is a massive, ongoing problem for the fashion industry. An RFID clothing tag doubles up as a clever security device, giving you a much more modern way to protect your stock. When you link the tags to readers at your store exits, you create a very effective electronic article surveillance (EAS) system.

If an item with a live tag is carried through the exit, an alarm sounds instantly, alerting staff. It’s a clear deterrent to would-be thieves, but it doesn’t get in the way of a good shopping experience for everyone else. And because every tag is unique, you can even see exactly which item was taken, which is incredibly useful data for your loss prevention strategy.

This isn’t a small issue in the UK. Reports in 2023/24 showed over 55,000 incidents of shoplifting per day, costing British retailers an estimated £2.2 billion. It’s no wonder that security tags with embedded RFID are becoming a go-to anti-theft measure. Combined with discreet antennas and inventory software, they create a point-of-exit system that stops theft without making honest customers feel uncomfortable. You can read more on how RFID is being used to tackle theft over on brc.org.uk.

All these operational gains lead to one thing: a much better experience for your customers. Accurate stock data is the backbone of modern retail, where the line between shopping online and in-store is disappearing.

Here’s how it makes a real difference:

By fixing fundamental problems like stock accuracy and security, an RFID clothing tag system helps you build a more efficient, resilient business. This strong foundation allows you to meet the incredibly high expectations of today’s shoppers, building loyalty and driving real growth.

Picking the right RFID tag for your clothing line isn’t as simple as just grabbing one off the shelf. The best choice is deeply tied to the garment itself-think about its material, its value, and how long you need to track it. A delicate silk dress, for instance, needs a completely different approach than a sturdy pair of work trousers. Getting this right is critical for a smooth and successful rollout.

You’re trying to strike a balance between aesthetics, durability, cost, and the practicalities of your production line. Each type of tag comes with its own set of pros and cons. Make the right call, and the tag will do its job perfectly without getting in the way of the customer’s experience or ruining the look of your clothes.

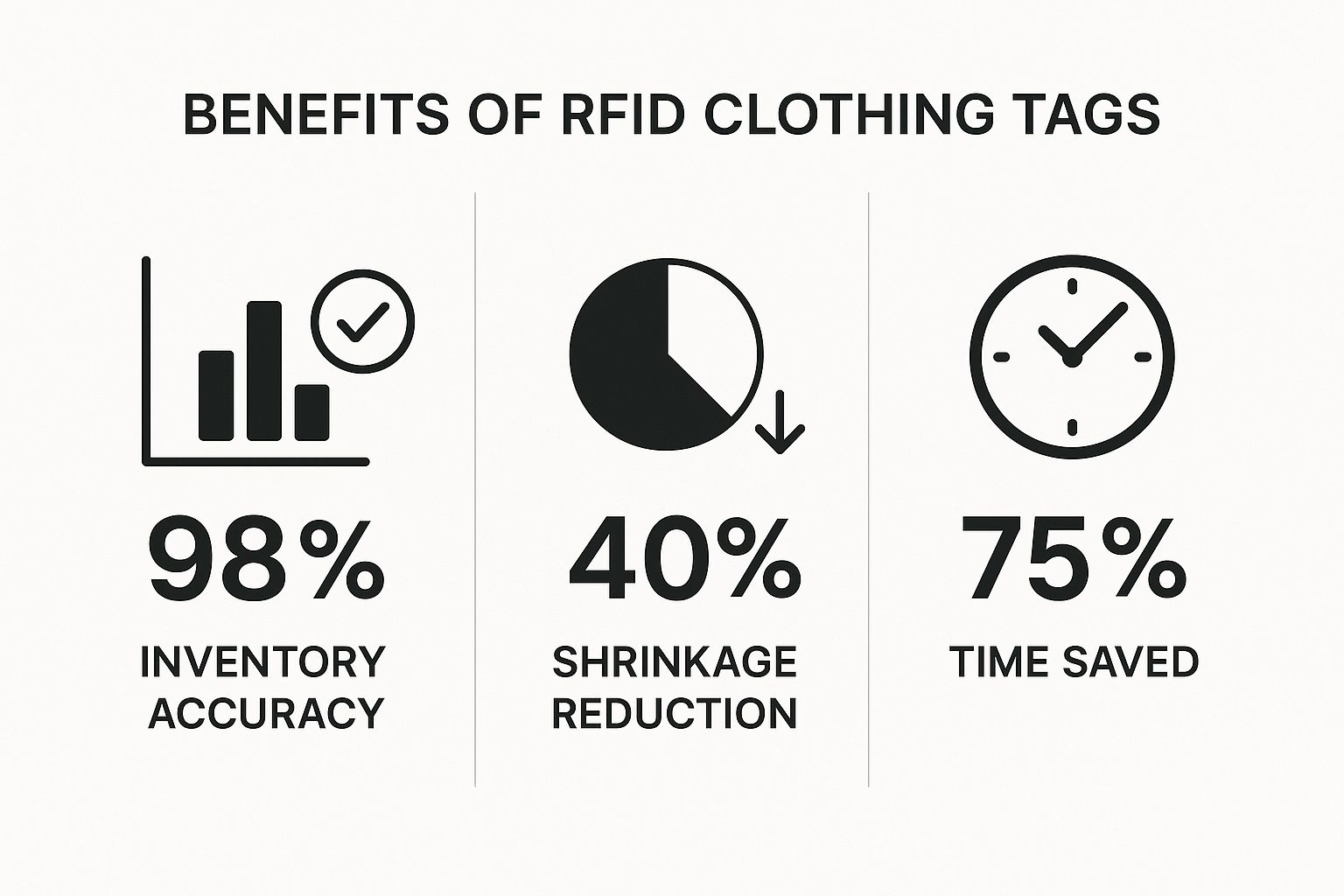

The benefits of getting it right are massive. Just look at the operational gains retailers are seeing.

With improvements like these on the table, it’s clear that spending a little time choosing the perfect tag is a worthwhile investment.

Let’s start with the most common format you’ll see: the RFID hang tag. It looks just like a standard cardboard hang tag, but it has a tiny, ultra-thin RFID inlay hidden inside. The beauty of this approach lies in its simplicity. You can attach them to pretty much any garment, and because the customer removes them after buying, any privacy concerns are immediately put to rest.

They’re also a fantastic, budget-friendly option for big rollouts, which is why they’re a firm favourite among high-street fashion brands. The market for these tags is already huge-valued at USD 5.24 billion in 2023-and it’s only set to get bigger as more retailers get on board.

For something a bit more permanent, you have RFID woven labels. These are clever little tags that get sewn right into a seam, often sitting next to the care label. They’re built to last the lifetime of the garment, surviving wash after wash. This makes them perfect for things like workwear, uniforms, or rental clothing where you need to track items long after they’ve left the shop.

Because they’re physically part of the garment, sewn-in labels are practically invisible and can’t be tampered with. This makes them great for security, but also for tracking an item’s entire lifecycle, which is becoming a big deal for brands focused on sustainability.

Their resilience comes from the protective shell around the chip and antenna, which is usually made of a flexible material like silicone. This casing shields the delicate electronics from water, heat, and the rough and tumble of a washing machine. For more detail on materials, our guide on label printing for clothing is a great resource.

Another flexible option is the adhesive RFID sticker. These are small, sticky labels that can be applied directly onto an existing tag, the packaging, or even somewhere discreet on the item itself. Their main advantage is speed; you can get them on items quickly and easily.

Stickers are a lifesaver for products that are tricky to tag otherwise, like shoes, bags, or other accessories. You can also add them at any stage in the supply chain, which is handy if you need to add RFID tracking to existing stock that’s already been made. The only thing to watch out for is making sure the adhesive is right for the fabric and how long it needs to stay put.

Finally, we have hard tags. You’ll recognise these. They’re the rigid plastic tags attached with a pin, much like traditional security tags. Inside, they have an RFID inlay that does two jobs in one: inventory management and anti-theft security (known as Electronic Article Surveillance, or EAS).

These are by far the toughest option and the best visual deterrent against theft. When a customer buys the item, the tag is removed at the till with a special tool and can be used again on the next piece of stock. That reusability makes them a very cost-effective choice for loss prevention, especially when you’re dealing with high-value items like designer coats or premium handbags.

To help you decide, here’s a quick breakdown of how the different tag formats stack up against each other.

| Tag Type | Best Use Case | Durability | Aesthetics | Cost |

|---|---|---|---|---|

| Hang Tags | High-volume retail, fast fashion | Low (single-use) | Visible, part of branding | Low |

| Woven/Sewn-In | Workwear, rentals, luxury goods | High (life of garment) | Discreet, integrated | Medium |

| Adhesive Stickers | Accessories, footwear, retrofitting | Medium (depends on adhesive) | Can be hidden | Low-Medium |

| Hard Tags | High-value items, loss prevention | Very High (reusable) | Highly visible deterrent | High (but reusable) |

As you can see, there’s a clear trade-off between things like visibility, durability, and cost. A simple hang tag is perfect for a fast-fashion t-shirt, while a high-end coat will benefit more from the security of a hard tag or the discreet permanence of a sewn-in label. It all comes down to finding the right fit for your product and your business goals.

So, you’re ready to bring RFID into your business. It’s a big move, and getting it right means having a clear plan. This isn’t just a tech upgrade; it’s a fundamental change to how you manage everything from your supply chain right through to the shop floor. The best way to tackle it is by breaking the process down into clear, manageable stages.

Think of it less like flicking a switch and more like building a foundation. You need to plan carefully, pick the right partners and tools, and get your team on board with a new way of working. A steady, methodical approach will help you spot and fix any snags early on, helping you reap the rewards from day one.

A successful rollout follows a logical path. You start with the big picture and gradually work your way to a full, business-wide deployment. Each step naturally leads to the next, making sure the technology, the software, and your people are all working in harmony.

An RFID clothing tag is just one part of the equation. To bring it to life, you need a complete toolkit of hardware to read the tags and smart software to make sense of all the data.

The UK is really embracing this technology. By 2024, the UK RFID market is set to be worth around USD 594.67 million, and it’s not slowing down. This growth is almost entirely down to retailers who are chasing the kind of efficiency these systems deliver. You can read more about the UK RFID market over at credenceresearch.com.

Even the best-laid plans can hit a bump in the road. Knowing what to watch out for ahead of time means you can have solutions ready and keep your project moving smoothly.

One of the most common hurdles is tag placement consistency. For readers to work reliably, every tag needs to be in the exact same spot on every garment. It sounds simple, but you’ll need to create crystal-clear guidelines for your suppliers.

Staff training is another huge piece of the puzzle. Your team needs to understand not just how the new system works, but why it makes their jobs easier. Proper training transforms employees into advocates for the technology, helping it get used to its full potential. For a wider perspective on this, you can check out our guide on https://sessionsuk.com/how-to-implement-labelling-solutions/. A bit of preparation here goes a long way.

The real power of an RFID clothing tag isn’t just about faster stocktakes or better security. Those benefits are huge, of course, but they’re really just the starting point. We’re seeing this technology become the data-centric heart of the entire retail experience, influencing everything from the fitting room to the future of sustainable fashion.

When you invest in an RFID system today, you’re not just fixing today’s logistical headaches. You’re building a foundation for what comes next. The data pouring in from every single tag allows you to build a smarter, more personal, and more responsible business.

Picture a fitting room that doubles as a personal stylist. That’s not science fiction; it’s one of the most exciting directions for RFID. When a customer walks into an interactive fitting room, a smart mirror instantly reads the tag on their chosen garment.

Suddenly, the mirror can show different sizes and colours, pull up customer reviews, or even suggest a pair of shoes to go with that dress. It turns a functional moment into an engaging experience. Better yet, the shopper can request another size right from the screen, without having to get dressed and head back out to the shop floor.

Research shows around 80% of business leaders agree that personalised experiences encourage customers to spend more. RFID-powered fitting rooms deliver that personal touch right when it matters most.

This isn’t just great for the customer. Retailers get a goldmine of data, seeing which items are tried on most but not purchased, which helps them understand customer interest far beyond simple sales data.

Sustainability is no longer a niche concern; it’s a core expectation for many shoppers. An RFID clothing tag gives brands a tangible tool to build a genuine circular economy. By embedding a tag into a garment from the very beginning, you can track its entire journey-from the factory floor to resale or recycling.

This unlocks a host of new, sustainable business models:

The boundary between online and in-store shopping is gone. RFID is the glue that binds these two worlds together, creating the joined-up omnichannel experience customers now expect.

Think about click-and-collect. Real-time stock visibility means that when a customer reserves an item online, you can be confident it’s actually on the shelf waiting for them. That same accuracy refines the returns process, getting products back on the floor and ready to be sold again much faster. As you look at where RFID is headed, it’s helpful to see it within the context of wider future trends in business automation that are reshaping the industry. This technology is a critical piece of a much bigger picture.

Switching to a new technology like RFID always brings up practical questions. How do the tags actually work day-to-day? What’s the real cost? And what does it mean for our customers? Getting straight answers to these common queries is the first step in deciding if RFID is the right move for your apparel business.

Let’s look at some of the most frequent questions we hear from brands just like yours.

Yes, absolutely. Most RFID tags designed to be a permanent part of a garment are built tough. Whether they’re sewn discreetly into a seam or heat-sealed directly onto the fabric, these tags are engineered to handle countless washes and last the entire life of the item.

The secret is in the construction. The delicate chip and antenna are encased in a protective shell, often made of flexible polymers or silicone. This little shield protects the electronics from water, detergent, heat, and the tumbling of a wash cycle. The only exception is the disposable paper hang tag with an RFID inlay – those are meant to be removed by the customer after purchase and won’t survive a wash.

This is a big one, and it’s a completely fair question. Thankfully, the way RFID is used in retail is designed to sidestep privacy issues. The vast majority of tags you’ll find in the fashion industry are passive RFID tags. This is a key detail – it means they have no battery or internal power source. They can only be “woken up” and read by a dedicated RFID scanner from a very short distance.

Once a customer buys an item, its unique ID number is disconnected from their personal details in the store’s system. To add another layer of security, many retailers automatically deactivate the tag at the till, making it unreadable. And for anyone still feeling uneasy, tags on stickers or hang tags can be easily removed and thrown away.

Pinning down a single price is tricky because the cost depends on the scale of your operation. The total investment isn’t just about the tags; it’s a package of several key components:

For a small independent boutique, the initial setup might run into a few thousand pounds. For a major retail chain with dozens of stores and a huge distribution centre, the cost will be much higher.

It’s helpful to think of it less as a cost and more as a long-term investment. The payback comes from huge gains in efficiency – think lightning-fast stock counts, a serious drop in theft, and more sales simply because you always know what you have in stock.

While they both help track products, RFID is a massive leap forward from the traditional barcode. The fundamental difference comes down to how they’re read.

Barcodes need a clear, direct line of sight. An employee has to aim a scanner at each barcode, one by one. It’s the reason manual stock-takes are so painfully slow and often riddled with human error.

An RFID clothing tag does not need to be seen to be counted. The radio waves from a reader can cut straight through fabric, cardboard boxes, and other materials, letting you scan hundreds of items in a matter of seconds. This single capability completely changes the game for inventory management.

Here’s a quick breakdown of the differences:

| Feature | Barcodes | RFID Tags |

|---|---|---|

| Line of Sight | Required | Not Required |

| Read Speed | One at a time | Hundreds per second |

| Identification | Identifies product type (SKU) | Identifies each unique item |

| Data Storage | Very Limited | Can store more data |

| Durability | Easily damaged or obscured | Often encased and more durable |

But the real magic of RFID is that every single tag has a unique serial number. A barcode is generic – all medium blue t-shirts in a batch will share the same barcode. With RFID, every individual medium blue t-shirt gets its own digital passport. This item-level tracking is what makes near-perfect stock accuracy and clever loss prevention strategies possible.

At Sessions UK, we provide the specialised labelling machinery you need to bring solutions like RFID into your production line smoothly. Whether you’re a growing brand or a large-scale manufacturer, our equipment helps you apply labels with the speed and precision your business relies on. Take a look at our range of labelling machines to find the right solution for your operation.

Copyright © 2025 Sessions Label Solutions Ltd.