Ever wondered what RFID labels are? They are like advanced barcodes. They use radio waves to talk wirelessly, meaning a standard barcode needs to be seen to be scanned, while an RFID label can broadcast its information from a tiny microchip and antenna to a nearby reader.

A good way to think about it is that an RFID label gives a physical object its own digital voice. It can announce who it is and share other details without ever being seen or handled directly. This is what makes the technology so brilliant for tracking and managing things in real time.

At the heart of every label is an integrated circuit (the microchip) that stores information, like a unique ID number. This chip is hooked up to an antenna, which picks up radio waves from a reader. It then uses the energy from those waves to send its own data back. The whole thing happens in a flash, and you can read hundreds of labels at once.

The real magic happens when two main parts work together:

This ability to communicate without a direct line of sight is what separates RFID from older tracking methods. Imagine a busy warehouse. A worker could scan an entire pallet of boxes in seconds without needing to unpack a single one. This same idea has completely changed other sectors, too, like retail, where the benefits of RFID tags for clothing have made stock management much easier.

RFID technology gives you a live, moment-by-moment view of your inventory. Businesses can track exactly where their products are and how many they have, slashing the risk of running out of stock or ordering too much. The result is a massive improvement in inventory accuracy.

How does this all come together? An RFID system is a team effort between three key players: the label itself (also called a tag), a reader, and the back-end software that makes sense of it all.

Think of it like a radio station. The reader is the broadcast tower, sending out a signal. The RFID label on your product is like a tiny pocket radio that catches that signal and replies with its own message.

It all kicks off when the reader emits a specific radio wave. For most labels, this wave does more than just ask for information-it provides the jolt of energy the label needs to wake up and respond. The label’s antenna picks up this energy, powering up the tiny microchip inside.

Once it’s awake, the chip transmits its stored data-maybe a unique serial number or product code-back to the reader. The reader captures this signal and sends the information on to a computer system, which might use it to update inventory counts or track an asset’s location. This whole conversation happens in the blink of an eye.

Not all RFID labels are built the same. They’re mainly sorted into different types based on how they get their power, which has a big impact on their range, size, and cost. Let’s break down the main categories.

| Feature | Passive RFID | Active RFID | Semi-Passive RFID |

|---|---|---|---|

| Power Source | Powered by the reader’s signal | Internal battery | Internal battery to power the chip |

| Read Range | Short (up to a few metres) | Long (up to 100 metres or more) | Medium (longer than passive) |

| Cost | Very low cost per label | Higher cost per label | Moderate cost |

| Size | Small and flexible | Larger and more rigid | Varies, typically smaller than active |

| Common Use | Retail inventory, access control, race timing | Container tracking, vehicle monitoring, large assets | Temperature-sensitive goods, high-value items |

As you can see, the choice comes down to what you need to track and over what kind of distance. Passive labels are fantastic for high-volume, low-cost items, whereas active labels are the heavy-lifters for valuable assets over large areas.

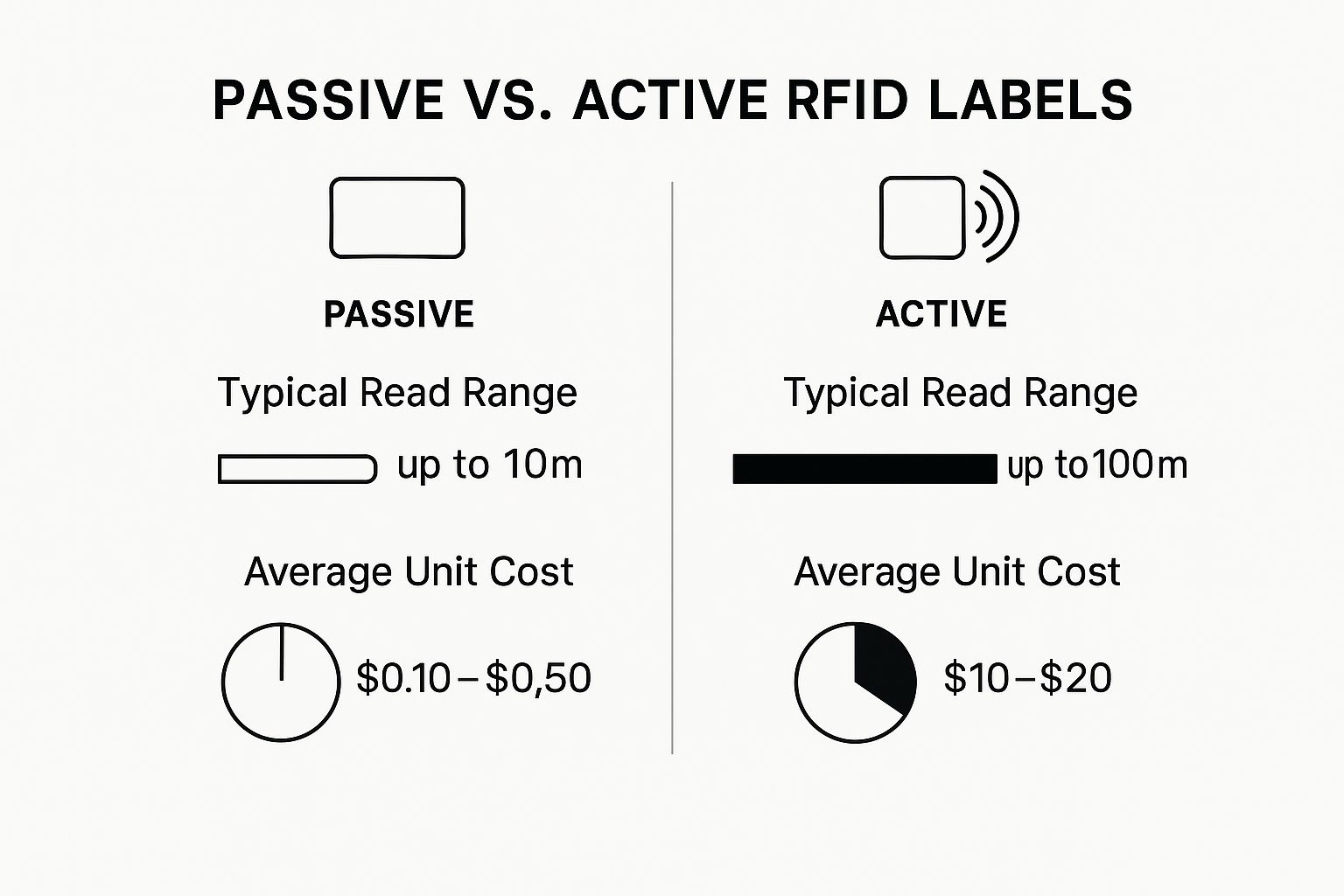

The image below gives a great visual comparison of the two most common types-passive and active-showing the clear trade-off between range and cost.

It’s pretty clear: if you need to scan something from far away, you’ll need an active label, but it comes at a much higher price per unit. For most everyday applications, the affordable and compact passive label is the perfect fit.

What does all this tech mean for a business on the ground? The benefits of switching to RFID labels are immediate and pretty significant. The main advantage is being able to grab huge amounts of data in a flash, with total accuracy, and without needing to see each item.

Think about the difference compared to traditional barcode scanning. Instead of a staff member painstakingly scanning one box at a time, they can now read hundreds of labels in seconds with a single sweep. This level of automation speeds up supply chain tasks, from logging incoming goods to getting orders out the door, all while cutting down on labour costs and simple human error.

Real-time tracking gives you an accurate, live picture of every single tagged item. This visibility is a major factor for inventory accuracy, helping to slash stockouts and avoid the cost of carrying too much dead stock.

Beyond simply counting stock, RFID labels bring a serious security upgrade. Every label has a unique ID that’s far more difficult to copy than a standard barcode. This helps businesses shut down theft and combat the spread of counterfeit products, protecting both their reputation and their bottom line.

For companies with a lot of valuable equipment to keep track of, RFID offers constant oversight. It’s a useful tool for monitoring the location and status of critical assets, whether that’s medical devices in a hospital or expensive tools on a sprawling construction site. The practical benefits here are clear:

The push for greater automation is driving huge growth in the market. Here in the UK, the RFID industry was valued at around USD 594.67 million and is expected to climb to USD 1,415.42 million by 2032. This boom is being led by sectors like logistics and healthcare, which depend on the real-time visibility and cost savings that RFID delivers. You can explore the trends with a full RFID market analysis.

Unlocking these benefits starts with applying the labels correctly. You can see how Sessions UK’s advanced labelling systems are engineered for the precision needed for RFID.

It’s one thing to understand the theory, but where is RFID technology making a difference? The answer is, pretty much everywhere. From retail floors to sterile hospital corridors, its practical uses are solving real-world problems with impressive results.

In a busy shop, for instance, RFID is the magic behind ‘smart shelving’. These shelves know exactly what’s on them, automatically flagging when a popular item is running low. This simple alert prevents those frustrating out-of-stock moments, keeping customers happy and sales flowing.

For businesses looking to get their stock control just right, RFID is a big help. It massively cuts down on manual counting and human error, a core principle in the best practices for inventory management.

Think about the journey a product takes. In logistics, RFID tags are slapped onto everything from individual parcels to entire pallets. This gives companies a bird’s-eye view of their goods moving through the supply chain. Scanners at warehouse doors or loading bays can read a whole shipment in seconds, a task that would have once taken ages of manual barcode scanning.

The healthcare sector has also seen huge benefits. Hospitals use RFID wristbands to instantly confirm a patient’s identity and pull up their medical history, drastically improving patient safety. It’s also used to keep track of expensive medical equipment, so staff can find that one available heart monitor in a massive hospital without wasting precious time.

By following individual components through an assembly line, manufacturers can pinpoint exactly where a quality issue occurred. This level of detail helps improve production flow and maintain high standards for finished goods.

This isn’t just a niche technology; it’s booming. The UK RFID market was valued at around USD 593.64 million and is expected to climb to an incredible USD 1,794.67 million by 2035. This surge is being driven by industries like manufacturing and retail as they embrace smarter, more automated ways of working.

Here are a few more snapshots of RFID in action:

Getting your RFID setup right from the start is critical. You can’t just pick any label off the shelf and expect it to work; a few key factors will make or break your system’s performance.

The first thing to look at is the item you’re tagging. Metal, for instance, is notorious for reflecting radio signals, while liquids can absorb them. Both scenarios can easily block a reader from getting a clean scan. You also have to consider the read distance you need. A label designed for scanning items a few centimetres away on a checkout counter is completely different from one needed to track a pallet from the other side of a massive warehouse.

Then there’s the environment itself. Will the labels have to put up with extreme heat, freezing temperatures, or constant moisture? There are specialised, rugged labels built for tough industrial conditions, so matching the label to its working environment is necessary for it to last.

Once you’ve picked the perfect label, applying it correctly is just as important as the choice itself. In fast-paced worlds like manufacturing or logistics, you need both speed and absolute precision. A wonky label can lead to a missed scan, and that single failure can throw a wrench into your entire tracking system.

Consistent placement is the name of the game. It makes sure that automated readers can pick up the signal every single time an item flies past a scanning point. This is where dedicated machinery really shines. For any business thinking about scaling up, it’s worth exploring the different kinds of label printing machines in the UK to see how automation can help.

Automated label applicators solve the biggest challenges in high-speed environments. They guarantee that every single RFID label is placed in the exact same spot, integrating perfectly into fast-moving production lines without causing bottlenecks.

Automated systems, like the ones we provide at Sessions UK, are engineered to apply these smart labels with incredible accuracy and speed. This machinery takes human error and guesswork out of the equation entirely. It helps the technology work flawlessly from the moment the label is applied, protecting your investment and delivering the reliable data you depend on, day in and day out.

The story of RFID is just getting started. We’re now seeing its true power unleashed as it pairs up with other technologies like the Internet of Things (IoT) and cloud computing. This powerful combination means businesses can gather a constant stream of real-time data from tagged items, then analyse it to make smarter decisions on the fly.

This opens up a world of possibilities. Think of smarter cities where RFID data from vehicles helps manage traffic flow. Or imagine a completely transparent food supply chain where you can trace an apple right back to the tree it was picked from. In retail, this could mean highly personalised shopping experiences, where a store understands your preferences the moment you step inside.

It’s no surprise that the market is taking notice. Europe’s RFID sector, with the UK as a key player, was valued at USD 4.44 billion and is forecast to hit USD 7.67 billion by 2033. This surge is fuelled by its proven ability to boost efficiency in logistics, manufacturing, and retail.

RFID is evolving from a simple tracking tool into a fundamental part of a company’s digital nervous system. It’s the critical bridge between our physical world and the digital data that drives it.

As RFID technology becomes more woven into our digital systems, its place at the heart of business operations is secured. It will continue to offer ever-more intelligent ways to manage everything from assets to information. For any business ready to jump in, it pays to first understand how to streamline labelling processes to get the most out of the technology from day one.

When you’re looking into a technology as powerful as RFID, it’s natural to have a few questions. You need to know the real-world ins and outs before diving in. Here are some of the most common queries we hear.

First up, security. People often ask, “Can someone hack or clone my RFID tags?” Technically, it’s possible, but for most business applications, the risk is incredibly low. Modern RFID labels come with security features like encryption, and the data stored on them-like a product ID-is usually of little value to anyone outside your operation.

This is a big one. It’s a common stumbling block for businesses wondering if RFID will work for their products. How do those radio signals cope with tricky materials like metal and liquid?

The short answer is that standard RFID labels struggle. Radio waves tend to bounce right off metal surfaces and get absorbed by liquids, which can seriously disrupt the signal between the label and the reader.

But there’s a solution. Specialised RFID labels have been developed for these challenges. You can get ‘on-metal’ tags designed to work perfectly on metallic assets, and liquid-resistant tags that are brilliant for tracking anything from bottled drinks to chemical drums.

It all comes down to choosing the right tool for the job.

And now for the million-dollar question: what’s the price tag? The cost of setting up an RFID system can vary enormously. It depends on what you need.

The price is influenced by the type of labels you choose (passive ones are pennies, active ones cost more), how many readers you need to cover your space, and the sophistication of the software required to make sense of all the data.

While there’s an upfront investment, most businesses discover that the long-term savings are significant. When you factor in reduced labour costs, near-perfect accuracy, and less stock loss, the return on investment often speaks for itself. The trick is to start with a clear, specific goal and build a system that fits what you actually need.

If you’re ready to explore how the right labelling machinery can integrate RFID into your production line, the team at Sessions UK can help. Find the perfect fit for your setup at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.