An anti tamper label is a clever seal designed to give you a clear, permanent sign if someone has tried to open or mess with a product. Think of it as a one-time security guard for your goods. Once it has been tampered with, the evidence is instant and impossible to hide, which is critical for protecting both the customer and the brand itself.

At its heart, an anti tamper label is a simple but incredibly effective security tool. Its main purpose is not to physically stop someone from getting into a package, but to make it glaringly obvious if they have tried. That is a very important distinction to make when you are figuring out the right security solution for your products.

People often get ‘tamper-evident’ and ‘tamper-proof’ mixed up. An anti tamper label is firmly in the first camp – it shows evidence of tampering. The term ‘tamper-proof’ suggests a completely unbreakable seal, which is practically impossible. Instead, these labels work by making sure any attempt to breach them leaves a lasting, tell-tale mark.

That visual signal from an anti tamper label does a few critical jobs for businesses in all sorts of industries. This is not just about sticking a label on a box; it is about creating a layer of trust and safety that starts on the factory floor and carries all the way through to the person using the product.

Let’s look at the core functions these labels perform.

| Function | Description | Primary Benefit |

|---|---|---|

| Consumer Safety | Shows products like pharmaceuticals or food have not been contaminated or swapped out. | Gives customers peace of mind that the product is safe to use or consume. |

| Brand Integrity | Prevents counterfeit goods from passing as genuine and stops fraudulent warranty claims on electronics. | Protects the brand’s reputation and bottom line from fraud and counterfeiting. |

| Regulatory Compliance | Helps businesses meet legal standards that require tamper-evident packaging in certain industries. | Avoids legal penalties and makes certain the product can be legally sold in its target market. |

By fulfilling these roles, anti tamper labels build a foundation of trust that benefits everyone.

This focus on safety and authenticity is why we are seeing such strong demand. In the United Kingdom, the market for these labels is expected to grow by around 3.8% each year. This is largely driven by customers being more aware of product safety and tighter rules in sectors like pharmaceuticals, where there is zero room for error.

A broken seal does more than indicate a compromised product; it erodes consumer confidence. The primary goal of an anti tamper label is to act as a clear, honest signal that the item is exactly as it was when it left the manufacturer.

The uses are incredibly broad. You will find them sealing everything from a jar of local honey to the warranty port on a new laptop. Wherever they are used, these labels are silent guardians of product integrity. For any business thinking about using them, getting to grips with the world of tamper-evident labelling is the first step toward better protection. By creating a clear warning system, these labels permit customers to make safer choices and help companies protect their products from threats throughout the supply chain.

The real genius of an anti-tamper label is that it is designed to fail, but in a very specific, obvious way. It is not just a sticker; it is a tiny security system engineered right into the material. The way these labels are made means that any attempt to peel them off triggers a permanent, irreversible change, giving you undeniable proof that someone has meddled with your product.

The material you choose dictates exactly how this proof appears. Each type uses a different trick – some shatter into countless pieces, while others leave a bold message behind. Getting to grips with how they work is the first step in picking the right kind of protection for your products.

One of the cleverest anti-tamper solutions uses frangible or destructible materials, like ultra-thin vinyl or specially treated brittle paper. Think of it like trying to peel off a layer of dried eggshell. Once it is stuck down, any effort to lift it causes it to crack and crumble into tiny, impossible-to-reassemble fragments. Removing the label in one piece just is not an option.

This self-destructing behaviour makes it perfect for sealing warranty ports on electronics or for asset-tagging valuable equipment. If someone tries to remove the label to get inside or swap an asset, they are left with a shredded, messy trail of evidence that screams “tampered with!”

What makes frangible labels so effective?

It is a straightforward but incredibly effective way to show interference. The immediate and permanent destruction of the label makes it a go-to choice for high-security applications where even a tiny breach needs to be spotted.

Another widely used material is void polyester, which operates on a clever delamination principle. These labels are built in two distinct layers. When a person attempts to peel one off, the top film separates from the bottom, leaving behind a hidden pattern or word – usually “VOID” – on the product’s surface. At the same time, that same pattern appears on the label itself.

The magic is in this dual-layer transfer. It makes certain evidence of tampering is left on both the product and the removed label, making it impossible for anyone to hide what they have done.

This approach is fantastic for sealing everything from pharmaceutical packaging and food containers to software boxes. The clear, printed warning gives an unambiguous signal that the seal has been broken.

The performance of a void label hinges on a few key elements:

For products that are vulnerable to moisture, water-soluble paper offers a unique kind of protection. This special material is engineered to completely dissolve when it comes into contact with water or other liquids. This gives it a dual function: it not only seals a product but also acts as an indicator for exposure to potentially damaging moisture.

This is especially handy for sensitive electronics or dry goods where even a small amount of water ingress could ruin the product. A dissolved or damaged label is an instant red flag, protecting the customer from a faulty item and the manufacturer from fraudulent warranty claims. This move towards such specialised labels reflects a broader industry trend. The adoption of tamper-evident labels in the UK is very much in step with global concerns over counterfeiting and the need for secure supply chains. An emerging trend is the shift to sustainable materials, with UK brands adopting eco-friendly components without sacrificing security. You can discover more insights about the growing tamper-evident market and its trends.

While the material gives an anti-tamper label its “how,” the type of label dictates its specific job and how it looks. Think of it like choosing the right tool for the job. You would not use a sledgehammer to hang a picture frame, and different products need different kinds of security. Choosing the right one is all about matching the label’s strengths to your product’s vulnerabilities.

It is a common misconception that all security labels are more or less the same. They are not. Some are designed to give an obvious, immediate warning, while others have more subtle features built in to outsmart sophisticated fraudsters. Understanding what makes each type tick is the key to picking a solution that offers the right level of protection without going overboard.

One of the most popular and straightforward options is the destructible vinyl label. The name says it all – these labels are engineered to fall apart if anyone tries to remove them. They are made from a very brittle vinyl film paired with a strong, aggressive adhesive, which means once they are on, they are really on.

Try to peel one off, and it will not lift cleanly. Instead, it will fracture into tiny, impossible-to-realign pieces. This makes them perfect for:

That immediate fragmentation is a powerful deterrent and leaves a clear-cut sign of tampering.

When you are up against the threat of counterfeiting, holographic seals are a fantastic two-for-one solution. They do not just show tampering; they provide a serious defence against fakes. These labels feature incredibly complex, multi-layered images that are exceptionally difficult to copy without highly specialised and expensive equipment.

If someone tries to remove a holographic seal, it will almost always destroy the intricate design or leave behind a tell-tale pattern. This blend of eye-catching visuals and high-level security makes them the go-to choice for pharmaceuticals, software, official documents, and high-end branded goods.

A hologram is like a unique fingerprint for your product. Its complexity and the difficulty in copying it create a formidable barrier against fakes, protecting both your brand’s reputation and your customers’ safety.

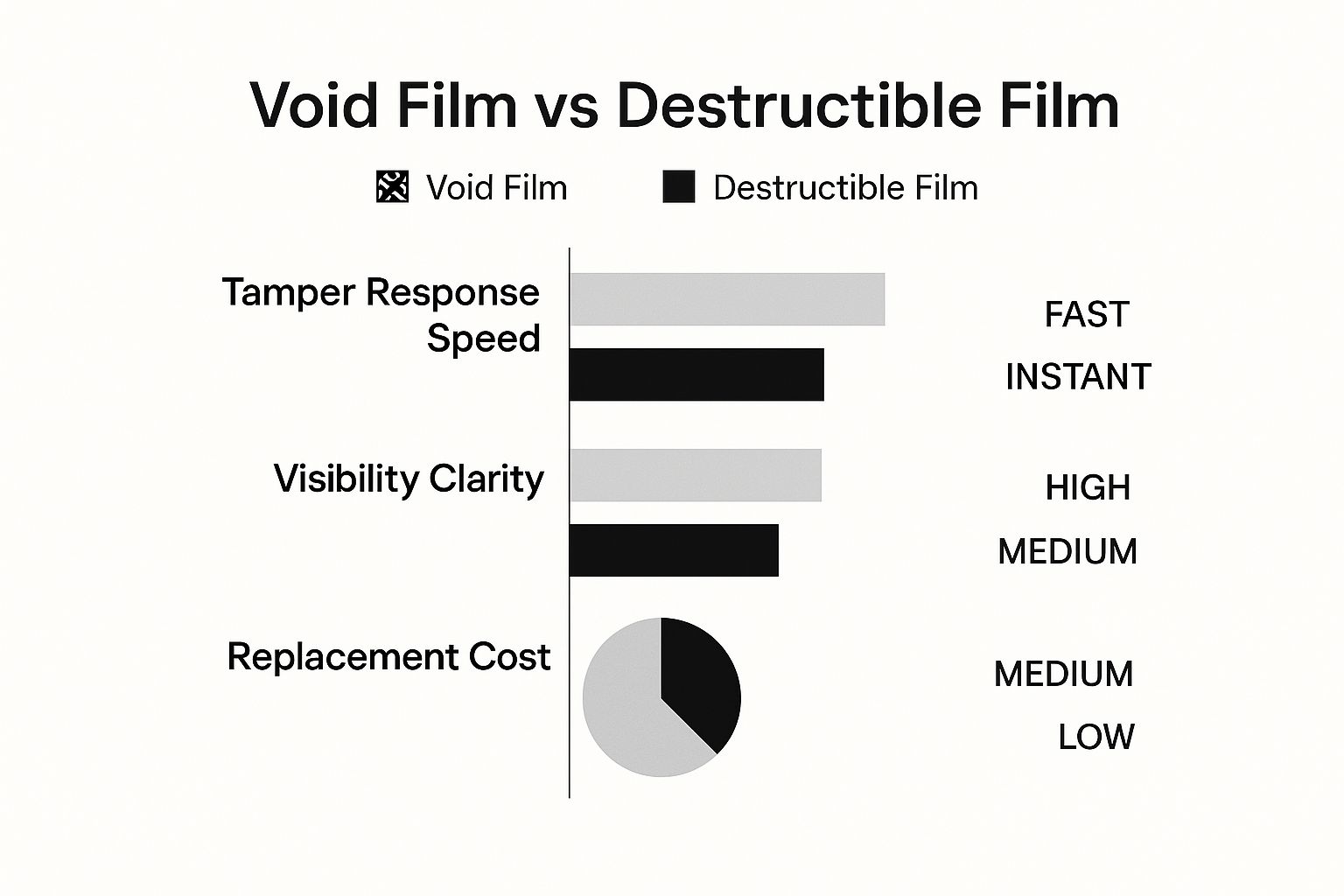

This image highlights the key differences between two common film technologies used in security labels.

As you can see, destructible films offer instant evidence by breaking apart, whereas void films provide a very clear visual message and can sometimes be more cost-effective, depending on what you need them for.

To help you decide, let’s look at a quick comparison of the main label types.

| Label Type | Tamper-Evident Mechanism | Best For | Security Level |

|---|---|---|---|

| Destructible Vinyl | Fractures into tiny pieces upon removal | Warranty seals, asset tags, calibration seals | High |

| Holographic Seal | Hologram is destroyed or leaves a residue | Anti-counterfeiting, brand protection | Very High |

| Void Label | Leaves a “VOID” or custom message behind | Sealing packaging, electronic components | Medium-High |

| Security Tape | Leaves a continuous “OPENED” message on the box | Sealing cartons, pallets, and large shipments | Medium |

Each of these labels has a distinct role to play in securing a product. The best choice always comes down to the specific risk you are trying to mitigate.

Moving from individual labels to sealing entire packages, security tape is an incredibly practical solution for cartons, crates, and pallets. It works just like regular packing tape but comes with a hidden security feature. If anyone tries to peel it off, it leaves behind a continuous, impossible-to-hide message, like “OPENED,” “VOID,” or even a custom brand logo.

This makes it incredibly easy for warehouse staff or the end customer to spot a compromised shipment with just a quick glance. It is a brilliantly efficient way to secure a whole package in one go, maintaining a clear chain of custody from your facility to its final destination.

To really step up your security, many anti-tamper labels can be printed with sequential numbers, barcodes, or QR codes. This simple addition turns a security seal into a powerful tool for tracking and verification.

By giving each label a unique identifier that is logged in a database, a business can:

This smart integration is a huge factor in the market’s growth. The global tamper-evident label industry is on the rise, with Europe alone projected to grow at a CAGR of around 4.2% between 2023 and 2033. As you can read in the full research about these market trends and projections, adding features like high-resolution printing, QR codes, and holography makes an anti-tamper label far more effective, which in turn fuels this growth. By understanding the options, businesses can fine-tune their security strategy to meet the exact risks they face.

An anti-tamper label is so much more than a sticker. Think of it as a crucial guarantee, a seal of trust that connects a manufacturer to a customer. Across countless industries, from life-saving medicines to the microchips in our phones, these labels offer a clear, unmistakable sign that a product is genuine, safe, and exactly as it left the factory. For some businesses, they are not just a ‘nice to have’ – they are fundamental to how they operate.

These labels are a first line of defence against a whole host of problems: contamination, fraud, and theft, to name a few. They do not just protect consumers from potential harm; they are also a key tool for safeguarding a company’s hard-won reputation and financial stability. The specific threats might change from one sector to another, but a well-designed security label is often the core of the solution.

Nowhere is the need for tamper-evident security more critical than in pharmaceuticals. When it comes to medicines and medical devices, product integrity is not just about quality – it can literally be a matter of life and death. A compromised product could have the wrong dose, be contaminated, or worse, be a complete fake with no active ingredient at all.

This is why strict regulations like the EU’s Falsified Medicines Directive (FMD) exist. They legally require tamper-evident features on prescription drug packaging, making these labels an absolute necessity. They serve several key functions:

In the food and beverage world, an anti-tamper label is a direct promise of freshness and safety. We have all seen it: a broken seal on a jar of sauce or a peeled-back lid on a carton of juice. It is an instant red flag that the product might be spoiled or, even worse, deliberately contaminated.

These seals are absolutely key for building consumer confidence, especially with the boom in food delivery services where products can pass through several hands. They show that your meal has remained untouched since it was sealed. For producers, this is key to minimising the risk of foodborne illnesses and the hugely expensive recalls and reputational damage that can follow.

An unbroken seal on a food product does more than just secure the lid. It communicates a clear message to the customer: “This product is safe, fresh, and exactly as we intended it to be.”

The electronics industry has its own unique set of headaches, from warranty fraud and component swapping to grey market sales. An anti-tamper label placed cleverly over a screw hole or casing seam is a simple but powerful deterrent. If a customer opens up a laptop to swap out a pricey component and then tries to return it, that broken seal tells the whole story.

This simple check protects manufacturers from fraudulent claims that can cost them millions every year. What is more, sequentially numbered or barcoded labels help track individual parts, adding another layer of security and control right through the supply chain.

When it comes to high-value goods like cosmetics, luxury fashion, and designer accessories, security labels are brilliant for preventing in-store tampering and theft. A customer just will not buy an expensive face cream if the seal is broken – that label reassures them they are the first person to open it.

In the world of logistics, security tapes and void labels are used to seal everything from individual cartons to entire pallets. They offer a quick, visual check for warehouse staff and delivery drivers, confirming at a glance that a shipment has not been opened in transit. This maintains a secure chain of custody all the way from the distribution centre to the final destination. You can explore more about the top industries that benefit from security labels in our detailed guide.

Choosing the right anti-tamper label is not just a simple procurement task; it is a critical decision that balances your security needs against practical, real-world factors. Get it wrong, and you could be looking at labels that fall off, offer flimsy protection, or simply cost more than they should. The real goal is to find that perfect match between the label’s properties – its material, adhesive, and security features – and the unique demands of your product and its journey to the customer.

It all starts by asking the right questions. Think about the surface you are sticking it to. A textured plastic container needs a completely different adhesive than a smooth glass vial or a porous cardboard box. For a label to do its job, it has to form a strong, unyielding bond with that surface.

Before you settle on a label, it pays to run through a quick mental checklist. Taking a systematic approach like this helps you sidestep common pitfalls, like choosing an adhesive that gives up in cold storage or a material that peels away from a curved surface.

Thinking through these points helps you build a profile of your ideal security solution. This is not just about picking a label off a shelf; it is about engineering a defence that is tailored to your product’s specific weaknesses.

Answering these questions gives you a much clearer path forward. For an even deeper look, our guide on how to choose security labels that actually protect your business assets can help you match the right solution to the right risk.

Here is a truth you can take to the bank: even the most advanced anti-tamper label is useless if the surface is not properly prepared. A clean, dry surface is non-negotiable for getting maximum adhesion. Any little bit of dust, grease, or moisture acts as a barrier between the adhesive and the product, fatally weakening the bond.

For the best results, just follow these simple prep steps:

This tiny bit of prep work makes a massive difference in how well your labels perform and how reliable they are in the long run.

The final piece of the puzzle is the application itself, which can be done either by hand or with specialised machinery. The best approach really hinges on your production volume, speed requirements, and the level of consistency you need.

Manual Application

This is the go-to method for small businesses, start-ups, and short production runs. It is wonderfully flexible and does not require any investment in equipment. An operator simply peels the label from its backing and applies it by hand. While it is cost-effective for smaller batches, it can be slow and often leads to slight inconsistencies in placement.

Automated Application

For high-volume manufacturing, automated labelling machines are the industry standard. These systems apply labels with incredible speed, precision, and flawless consistency – something that is absolutely key in regulated industries like pharmaceuticals. Automated systems, like those we provide at Sessions UK, can be integrated directly into your production line to handle everything from bottle labelling to carton sealing. This takes human error out of the equation and keeps things moving at high speed without ever compromising on security.

Applying an anti-tamper label is often more than just a good security practice – in many industries, it is a legal requirement. Trying to navigate the web of regulatory standards can feel overwhelming, but for any business, it is a crucial part of the process. Especially if you are in pharmaceuticals or food, compliance is not just about ticking boxes; it is about protecting consumers and steering clear of hefty penalties.

Simply sticking any old label on a product will not cut it. To be legally compliant, a tamper-evident feature has to meet very specific criteria laid out by regulatory bodies. It needs to have a unique design that is not easy for counterfeiters to copy, and it must show clear, permanent proof if someone has tried to open the package.

In the UK, packaging rules draw from our own domestic standards and guidelines set by international organisations. Two of the big players whose guidelines often set the global standard are the US Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

For any pharmaceutical business operating in the UK and Europe, the Falsified Medicines Directive (FMD) is a piece of legislation you absolutely must know. It makes two safety features mandatory on the packaging of most prescription medicines:

Thanks to this directive, a compliant anti-tamper label is now a required, non-negotiable part of the packaging line. The whole point is to build a secure supply chain that can flag and remove fake medicines before they ever get into a patient’s hands. You can learn more about the critical role of security labels in the pharmaceutical industry and how they help meet these strict rules.

An effective tamper-evident system is one that cannot be breached without leaving visible, permanent proof. The regulations are designed to a standard where a consumer can confidently identify if a product is safe to use with a quick visual inspection.

True compliance is not just about the label itself, but how it works with the entire package. A truly compliant system confirms that evidence of tampering is left behind, even if someone tries to fix the seal or stick it back down. This is exactly why materials like destructible vinyl or void-pattern polyester are so popular – the way they break is built into their design and simply cannot be undone.

The same core principles apply to food products, even if the specific rules differ. The Food Safety Act 1990 gives UK authorities the power to take action against food that is unsafe or misleading. A broken seal on a jar of sauce or a carton of milk can make the product legally non-compliant because its safety is no longer guaranteed. Choosing a certified solution designed to meet these standards is the only reliable way to protect both your business and your customers.

Looking into product security can feel a bit overwhelming, and it is natural to have questions. To help clear things up, I have put together answers to some of the most common queries we hear about using anti-tamper labels to protect your products.

It is a great question, as the two terms sound almost interchangeable but actually describe very different security functions. Think of it this way:

A tamper-evident feature, like a security label that leaves a “VOID” pattern when peeled off, is all about showing proof. Its entire job is to provide a crystal-clear, visible sign that someone has tried to open or meddle with the product.

Tamper-resistant packaging, on the other hand, is designed to be physically difficult to get into. It is the barrier itself. Most security labels are firmly in the tamper-evident camp because their purpose is not to stop someone from trying, but to make certain everyone knows they did.

High-quality anti-tamper labels are specifically engineered to be a one-shot deal. Once they are on, they are on for good. Features like ultra-destructible materials that shatter into tiny pieces or films that leave behind a sticky residue are designed to self-destruct the moment someone tries to remove them. This makes it virtually impossible to peel one off and reapply it without leaving a glaringly obvious mess.

Of course, no security measure is 100% foolproof. But a well-designed label makes tampering so difficult and obvious that it completely defeats the purpose for anyone trying to be sneaky.

An anti-tamper label is not meant to be a fortress. Think of it more like a silent witness. Its real strength is that it cannot be repaired or reused, creating a trustworthy, one-time seal that speaks volumes about your product’s integrity.

Choosing the right label for a surface that is not perfectly flat is all about getting the material and adhesive just right. You need a combination of flexibility and sticking power. For the best results, look for a thin, pliable label material like a soft vinyl or polyester, and pair it with a strong adhesive that can conform to the shape.

Here are a couple of real-world examples:

My best advice? Always test a few samples on your actual product before placing a big order. It is the only way to be certain the label sticks properly and will hold up in the real world.

Absolutely. The demand for sustainable packaging has pushed the industry forward, and there are now some great green alternatives available. You can find security labels made from recycled materials, papers certified by the Forest Stewardship Council (FSC), and even adhesives formulated to have a smaller environmental footprint.

Some brands are also getting creative by building tamper-evident features directly into their packaging design, which helps cut down on waste altogether. If sustainability is a core value for your business, it is definitely worth asking your supplier about the material’s lifecycle and composition.

At Sessions UK, we’re the experts in the machinery needed to apply your anti-tamper labels with the precision and speed your production line demands. Whether you are a growing business needing a semi-automatic system or a large-scale operation requiring a high-speed automatic labeller, our equipment is built to fit right into your workflow. Protect your products and boost your efficiency with our reliable machinery and expert guidance.

Find the perfect labelling solution for your business at sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.