Picture a worker that never gets tired, never slows down, and applies thousands of labels an hour with pinpoint accuracy. That’s the reality of an automatic labeller machine on a modern production line. It is the simple, powerful solution to the speed and precision challenges that manual labelling cannot overcome, making it a key piece of kit for efficient manufacturing and logistics here in the UK.

Whether you’re a small artisan food producer or a massive pharmaceutical plant, consistency is everything. When you rely on people to apply labels, you get human error. Labels end up crooked, in the wrong spot, or wrinkled, all of which makes a product look unprofessional.

An automatic labeller gets rid of that guesswork. It does the same job, the same way, thousands of times over without a single dip in quality. This kind of mechanical precision is brilliant for your brand image, making certain every item that leaves your facility looks exactly as it should. In competitive markets, that level of professionalism is a requirement, not a bonus.

Understanding how these machines operate is straightforward because the process is so logical. While different models have their own bells and whistles, the basic steps are always the same- and they are all about efficiency.

It all starts when a product, say a bottle or a box, enters the machine on a conveyor. This belt moves the item along at a steady, controlled pace towards the labelling station, which is the first step for getting the label in the right place.

As the product gets closer, a sensor- the machine’s “eye”- detects it and pinpoints its exact position. This triggers the next step at just the right microsecond, something that sets a reliable automated system apart from everything else.

As soon as the sensor gives the signal, the label applicator head springs into action. It peels a single label from a large roll and presses it firmly onto the product’s surface, all in a fraction of a second.

With its new label perfectly applied, the product continues its journey down the conveyor for the next stage, like being boxed up or shrink-wrapped. The whole operation is one smooth, continuous flow designed for speed and reliability.

Operations managers are always juggling the same key challenges: keeping up production speed, maintaining accuracy, and keeping a lid on labour costs. An automatic labeller hits all three of these problems head-on.

Here’s a quick look at how automation makes a difference:

To really get what an automatic labeller does, it helps to peek under the bonnet and see how it all fits together. Imagine a finely tuned assembly line, but its one and only job is to stick a label on perfectly, time after time. It all kicks off the moment a product enters the system.

This whole process is like a precise mechanical routine. Every part has a role, and they all work in sync to hit speeds and accuracy levels you could never dream of achieving by hand. From the second a bottle, box, or jar glides onto the line, the machine is in full control.

First up, you have the conveyor system. This is the road that carries each product through the labelling process. It moves at a steady, adjustable speed, which you can set to match your production line’s rhythm, making certain every item hits the labelling station at just the right second.

As a product zips along the conveyor, it’s kept in line by guide rails. These rails stop it from wobbling, tipping, or shifting out of place. That stability is absolutely critical for getting the label applied straight and in the exact spot you want it on every single unit.

The conveyor’s smooth glide carries the product towards its next stop: the sensor array.

Next, a series of sensors act as the machine’s eyes. These are usually photoelectric or ultrasonic, and they spot the exact moment a product enters the labelling zone. This triggers an electronic signal, which wakes up the most important part of the machine- the label applicator head.

The applicator head is where all the magic happens. It holds the big roll of labels and the mechanism that slaps them on. There are a few different types, each designed for a particular job:

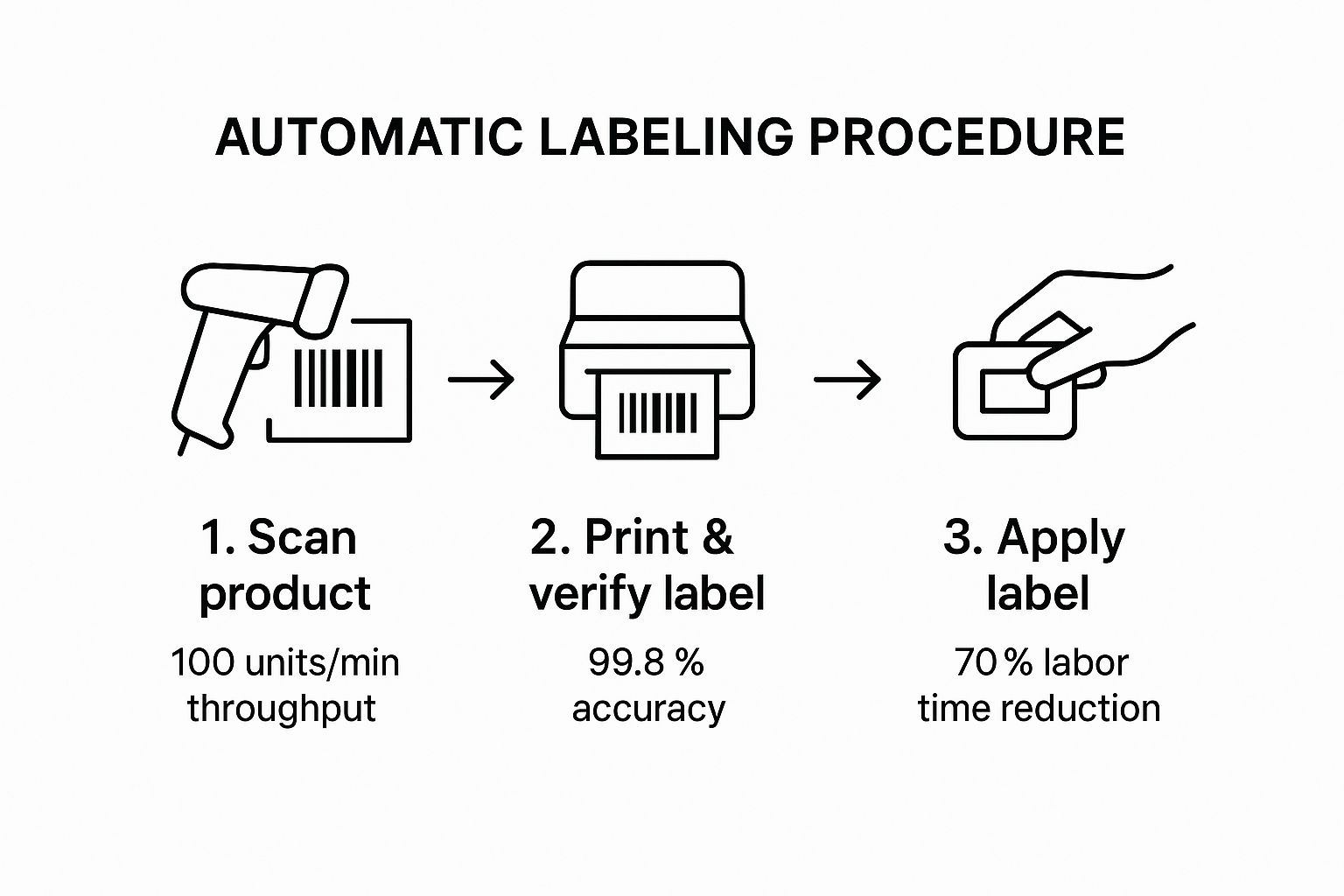

This infographic gives you a simple, three-step look at how the process flows, pointing out some of the key performance wins.

As you can see, scanning, printing, and applying all come together to deliver impressive throughput and big savings on labour.

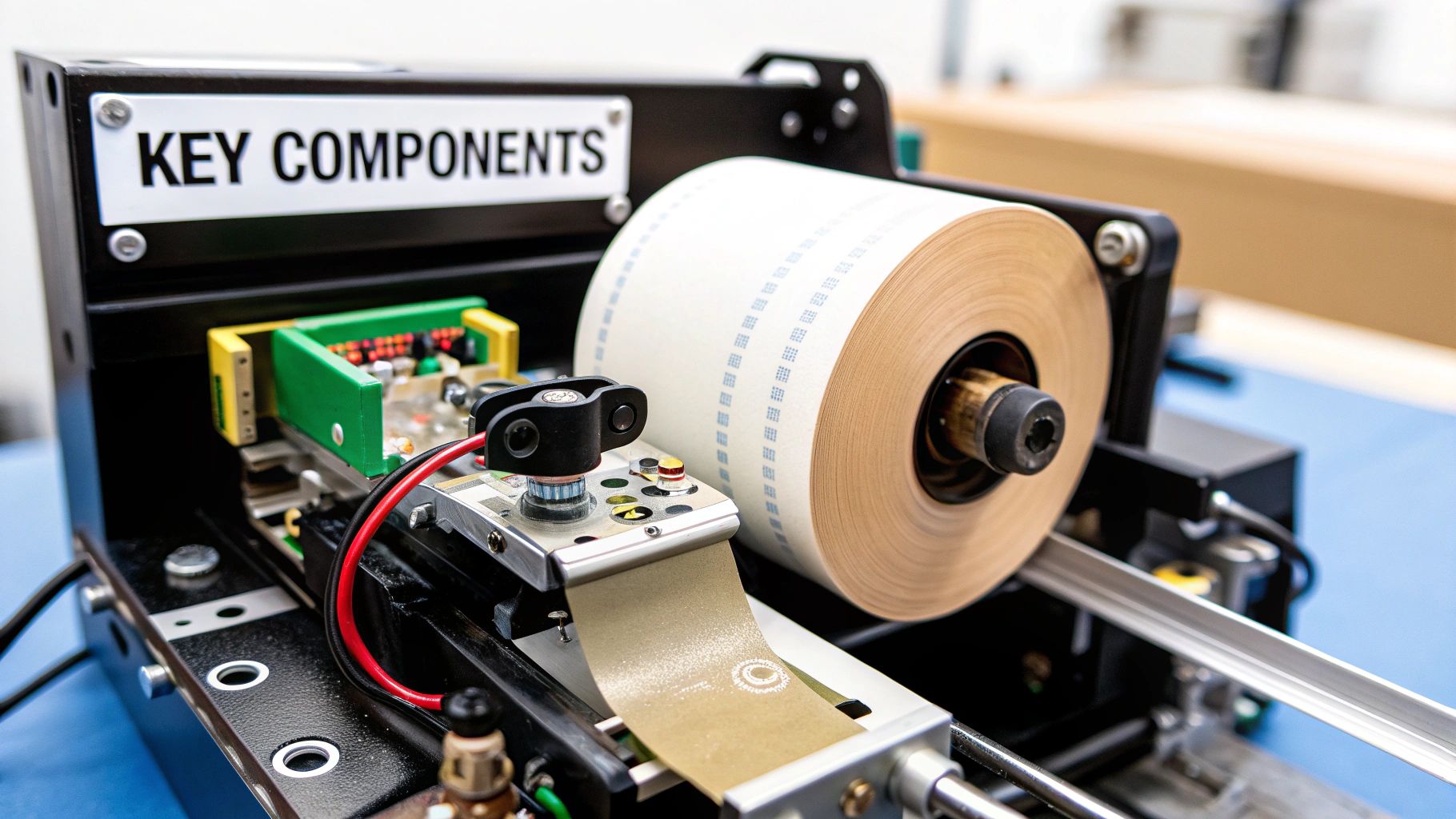

For the whole thing to run smoothly without jamming up, two other systems are needed. The drive motor and the web tensioning system work as a team to manage the roll of labels, which in the trade is called the “web.”

The drive motor is what pulls the backing paper, peeling a fresh label off and getting it ready for the applicator head. At the same time, the tensioning system keeps the label web tight, stopping it from wrinkling or tearing. It’s this constant, controlled tension that allows the machine to fire out hundreds of labels a minute with almost flawless reliability. This is a core part of what makes the different https://sessionsuk.com/automatic-label-applicators/ so incredibly effective on a busy production line.

The entire operation is managed from a central control panel. Think of it as the machine’s brain. From here, an operator can tweak the speed, adjust sensor sensitivity, and program different setups for various product sizes. Most modern panels now have touchscreens, making adjustments dead simple.

To get the full picture, it is often useful to understand the other bits of kit that work alongside the labeller. For example, knowing the basics of setting up a thermal label printer helps explain how print-and-apply systems can create labels on the fly, just before they’re applied. It’s all these integrated parts that create a complete, functioning solution.

Picking out an automatic labeller is a big decision for any business. It’s a serious investment that will directly shape your production line’s efficiency for years to come. Think of it less like buying a piece of equipment and more like finding the missing piece to your operational puzzle. The right machine will slot in perfectly, matching your product types, production speed, and where you see your business heading.

Get it wrong, though, and you’re looking at production bottlenecks, wasted labels, and endless tweaking. To steer clear of that headache, you need to step back and analyse your exact requirements before you even start looking at models. This means getting forensic about your products, your current setup, and your plans for growth.

The first thing to pin down is how fast you need to go. In the labelling world, this is measured in labels per minute (LPM). A small business bottling artisan sauces might get by perfectly with a machine handling 30-50 products a minute. A major beverage company will need a powerhouse system that can label several hundred bottles per minute just to keep pace with its filling line.

Here’s a tip: always plan for your busiest day, not your average one. If you buy a machine that just about covers your current output, you’ve left yourself no wiggle room for seasonal rushes or future growth. It’s almost always smarter to choose a model with a slightly higher LPM capacity than you think you need right now. For a deeper look, it’s worth reading a full guide on choosing the right labelling machine for your business.

It sounds obvious, but the physical characteristics of your products and labels are massively important. You have to be certain that the machine you’re looking at can handle your specific containers.

Start by asking yourself a few key questions:

A bit of advice from experience: always send samples of all your containers and labels to any potential supplier. This lets them run real-world tests to confirm the equipment will perform exactly as you need it to, which helps you avoid nasty compatibility surprises after installation.

The applicator head is the business end of the machine- it’s the part that physically applies the label. The type you need comes down to your product’s shape and the material it’s made from, as different technologies have very different strengths.

To help you get a clear picture, we’ve put together a quick comparison of the main applicator types. This should help you figure out which technology is the best fit for your products and operational needs.

| Applicator Type | Best For | Application Method | Key Advantage |

|---|---|---|---|

| Wipe-On | Flat or gently curved surfaces | A roller or brush presses the label on as the product passes. | Simple, reliable, and excellent for high-speed applications. |

| Tamp-Blow | Recessed areas or delicate items | A pad extends and a puff of air blows the label onto the product. | Non-contact application protects fragile products and surfaces. |

| Air-Blow | Lightweight or uneven products | A jet of air blows the label across a short distance without any contact. | Fast and gentle, ideal for items that cannot be touched. |

Once you’ve looked at the applicator type, the next big thing is adjustability. If you’re running multiple product lines with different containers, you’ll need a system that makes changeovers quick and painless. Look for features like tool-free adjustments for guide rails and applicator height. A machine that takes hours to reconfigure will create serious downtime, completely cancelling out the benefits of automation in the first place. The aim should always be to find a system that adapts to your needs with minimal fuss.

Automatic labelling machines aren’t a niche piece of kit for one or two sectors. Their value shines in any industry where speed, accuracy, and compliance are non-negotiable. From the food on our tables to the medicines in our cabinets, automated labelling is the invisible engine that makes certain products are correctly identified, safe, and professionally presented. Its adoption is so widespread simply because it solves universal production line headaches.

Here in the UK, the focus has always been on tight quality control and high packaging standards. This has naturally driven the move towards automated systems. Labelling is a critical link in the chain for UK industries like food, pharmaceuticals, and cosmetics- all of which are governed by strict regulations for consumer safety and traceability. UK manufacturers rely on automatic labellers to meet these rules and keep up with production speeds that are impossible to sustain with manual work.

In the fast-paced world of food and drink, presentation and information are everything. An automatic labeler machine is the real workhorse of this industry, applying labels to countless products every single day. Just think of the jars of jam, bottles of craft beer, or ready-meal packages lining supermarket shelves.

Each of those labels must carry precise ingredient lists, allergen warnings, and expiry dates. A misaligned or wrinkled label just looks unprofessional, but an inaccurate one could pose a genuine health risk. Automated systems make certain every single item gets a perfectly placed, legible label, protecting brand integrity and meeting strict food safety standards. To learn more, check out our 2025-labelling-for-food-products-guide/.

Nowhere is labelling accuracy more critical than in pharmaceuticals. The margin for error here is zero. For applying labels to vials, medicine boxes, and blister packs with absolute precision, an automatic labeller is simply indispensable.

These labels often carry information like serial numbers, batch codes, and dosage instructions, all required to meet Medicines and Healthcare products Regulatory Agency (MHRA) regulations. Automated systems deliver the consistency and traceability needed for patient safety. They can apply tiny labels to curved vials or add tamper-evident seals to cartons- tasks that are incredibly difficult to perform reliably by hand at scale.

For pharmaceutical companies, an automatic labeller isn’t just about efficiency; it’s a core component of their quality assurance and regulatory compliance. It provides a verifiable process that guarantees every product is correctly and securely labelled before it reaches a patient.

For cosmetics and personal care brands, the label is a huge part of the product’s appeal. It communicates brand identity, quality, and a sense of luxury. A crooked or bubbly label can instantly cheapen the perception of a high-end cream or perfume.

This industry is also known for its uniquely shaped containers, from tapered bottles to small pots, which are a nightmare for manual application. An automatic labeler machine designed for cosmetics can handle these unconventional shapes with ease, applying clear, metallic, or textured labels flawlessly to create that premium finish.

In the world of logistics and e-commerce, speed is everything. Every second counts in a busy fulfilment centre. Here, automatic labellers apply shipping labels to thousands of parcels an hour, making certain each one is correctly addressed and tracked.

These systems integrate directly with warehouse management software to print and apply unique shipping labels on the fly. This automation completely removes a major bottleneck in the dispatch process, which means fewer shipping errors and a better chance of hitting tight delivery deadlines. While automatic labellers boost efficiency, many businesses are also turning their attention to sustainability. For more on this, you can read about carbon footprint tracking for manufacturing.

Bringing an automatic labeler machine into your operation is a serious financial move, and looking at the sticker price is just the start. To make a smart decision and build a strong case for the investment, you need to work out its potential return on investment (ROI). It’s all about weighing the real-world gains against the total cost of ownership over time.

The first step is to pin down the tangible savings- the hard numbers that directly boost your bottom line and make the initial spend worthwhile.

The biggest and most obvious saving is almost always labour. Think about it: how many hours do your staff spend sticking on labels by hand every week? Multiply those hours by their wages, and you’ll quickly see what you’re currently spending just on this one task. An automatic system does the same job with minimal supervision, freeing up your team for more complex, valuable work.

Next up is the sheer increase in speed and output. An automated labeller runs rings around a human, letting you push more products through the line without hiring more people. This directly translates to processing more orders and boosting revenue, all within your existing setup.

Don’t forget about waste reduction, either. Hand-labelling is prone to mistakes- crooked, wrinkled, or misplaced labels mean you often have to scrap the label and sometimes the packaging itself. A machine applies labels with near-perfect precision every time, slashing your material waste and rework costs.

To get a clear picture of your ROI, you have to balance these savings against the full investment. And that means looking beyond the machine’s purchase price.

Your total investment should cover:

Staying on top of maintenance is key to getting the most out of your machine for years to come. For some solid advice on setting up a schedule, it’s worth reading about labelling machinery maintenance. A well-cared-for machine prevents costly downtime and protects your investment.

Some of the biggest wins aren’t easily tracked on a spreadsheet, but they are incredibly valuable. For example, the consistent, professional look of perfectly applied labels seriously lifts your brand image and builds trust with customers. That clean finish can be the very thing that makes a shopper pick your product over a competitor’s.

Another massive advantage is the newfound capacity for growth. With an automatic labeller, your business can confidently take on larger orders or expand its product range without the headache and cost of hiring more staff. That kind of operational agility is a positive for any ambitious company.

The UK’s automatic labelling machine sector is growing, which is part of a bigger shift towards automation in packaging. The global market, valued at USD 2.69 billion in 2024, is expected to hit USD 3.42 billion by 2029. This boom is being fuelled by industries like fast-moving consumer goods and e-commerce, where getting labels on quickly and accurately is non-negotiable. You can dig into more stats about the automatic labeling machine market on ResearchAndMarkets.com.

The world of labelling automation never stands still. The machines we see tomorrow will be smarter, more connected, and more environmentally friendly than ever before. We’re not just talking about small improvements here; we’re looking at a fundamental change in how manufacturers think about packaging and product identification.

The next wave of labellers is all about communication and data. This is where the Internet of Things (IoT) really starts to shine. Imagine a machine that can be monitored and managed from anywhere with an internet connection. An operations manager could check production speeds, get an alert for low label stock, or even run remote diagnostics from their tablet, catching potential problems long before they lead to downtime.

Another huge leap forward is the integration of advanced vision systems. Think of them as high-speed cameras paired with clever software, inspecting every single label for defects as it flies down the line. The system can check for perfect placement, print quality, and barcode readability, instantly rejecting any product that doesn’t meet the mark. It’s a powerful layer of quality control that doesn’t sacrifice speed.

At the same time, there’s a serious push towards greener, more sustainable practices. A major trend right now is the development of machines built to handle linerless labels.

Linerless labels are a brilliant example of this shift. They come on a roll with no backing paper, which means zero waste to throw away. Even better, you can fit up to 50% more labels on a single roll, which cuts down on material use and shipping costs.

This eco-friendly approach is becoming a priority for companies looking to shrink their environmental footprint.

Flexibility is another key driver of change. The growing popularity of print-and-apply systems gives businesses the power to print variable information- like batch codes, expiry dates, or unique serial numbers- directly onto a label just seconds before it’s applied. This is necessary for industries like pharmaceuticals or high-value foods, where total product traceability is non-negotiable.

All this progress points to a thriving market. The UK’s automatic labelling sector has seen steady growth as everyone from food producers to pharmaceutical companies gets on board with automation. The global labelling machine market was valued at around USD 11.9 billion in 2024, and Europe plays a huge part in that, thanks to strict regulations and industrial growth. Projections show this upward trend continuing, fuelled by the boom in e-commerce and the need for better traceability to meet UK and EU standards. You can dig deeper into the labelling machines market at Future Market Insights.

Even after looking into the details, it’s completely normal to have a few practical questions rattling around. Let’s tackle some of the most common queries we hear from businesses thinking about bringing an automatic labeler machine on board.

Getting these final points ironed out is often the last step before you can confidently move forward and make sure you get the most out of your new equipment from the get-go.

Keeping your labeller in top shape is all about a simple, consistent routine. Think of it like a quick daily check-up. Wiping down sensors and applicator pads to get rid of any dust or sticky residue is a must – it’s amazing how a little bit of build-up can throw off accuracy.

Beyond that, a weekly glance at the rollers to check for wear and a monthly lubrication of moving parts will keep everything running smoothly. Most manufacturers also suggest a yearly professional service, just to be safe. Trust me, keeping a simple log of these tasks is the best way to avoid surprise breakdowns.

Following the manufacturer’s maintenance guide isn’t just a suggestion; it’s the single best thing you can do for the machine’s long-term health. A little bit of consistent care stops tiny issues from turning into massive headaches.

Absolutely. Versatility is one of the biggest selling points of modern automatic labellers. Most are designed to be incredibly flexible, with features like adjustable guide rails, different applicator heads you can swap out, and software that saves settings for each of your products.

This means you can switch from labelling a small, round bottle to a big, rectangular box in just a few minutes. The key is to be upfront with your supplier. Give them the full picture of every product and label you use so they can point you to a model that can handle your entire range without creating a bottleneck every time you change over.

Honestly, it depends on what your current line looks like, but most modern labellers are built for a pretty painless installation. They almost always come with variable speed controls that can sync up with your conveyor’s pace. For power, they usually just need a standard electrical supply and, in some cases, a compressed air line.

Things get a bit more involved if you need complex data communication, like with a print-and-apply system that pulls info from your database. In that case, you might need a specialist to help. It’s always a smart move to walk your supplier through your current setup before buying anything – they’ll give you a clear idea of what the integration will actually involve.

Ready to put labelling errors and production slowdowns behind you? Sessions UK offers a complete range of automatic labeller machines known for their reliability and precision. Explore our solutions and find the perfect fit for your business.

Copyright © 2026 Sessions Label Solutions Ltd.