Choosing the right method for clothing labels printing is a big decision. It is one of those details that defines your brand’s quality and identity. More than just a legal tick-box, your label is a direct line to your customer, and it says a lot about your attention to detail. This guide will give you a clear path forward, helping you make smart choices on everything from materials to production.

A clothing label is much more than a bit of fabric sewn into a seam. Think of it as your brand’s handshake with the customer- it communicates quality and professionalism before they have even tried the garment on. A thoughtfully designed label can help justify a higher price, build trust, and make a lasting impression that sets you apart in a crowded market.

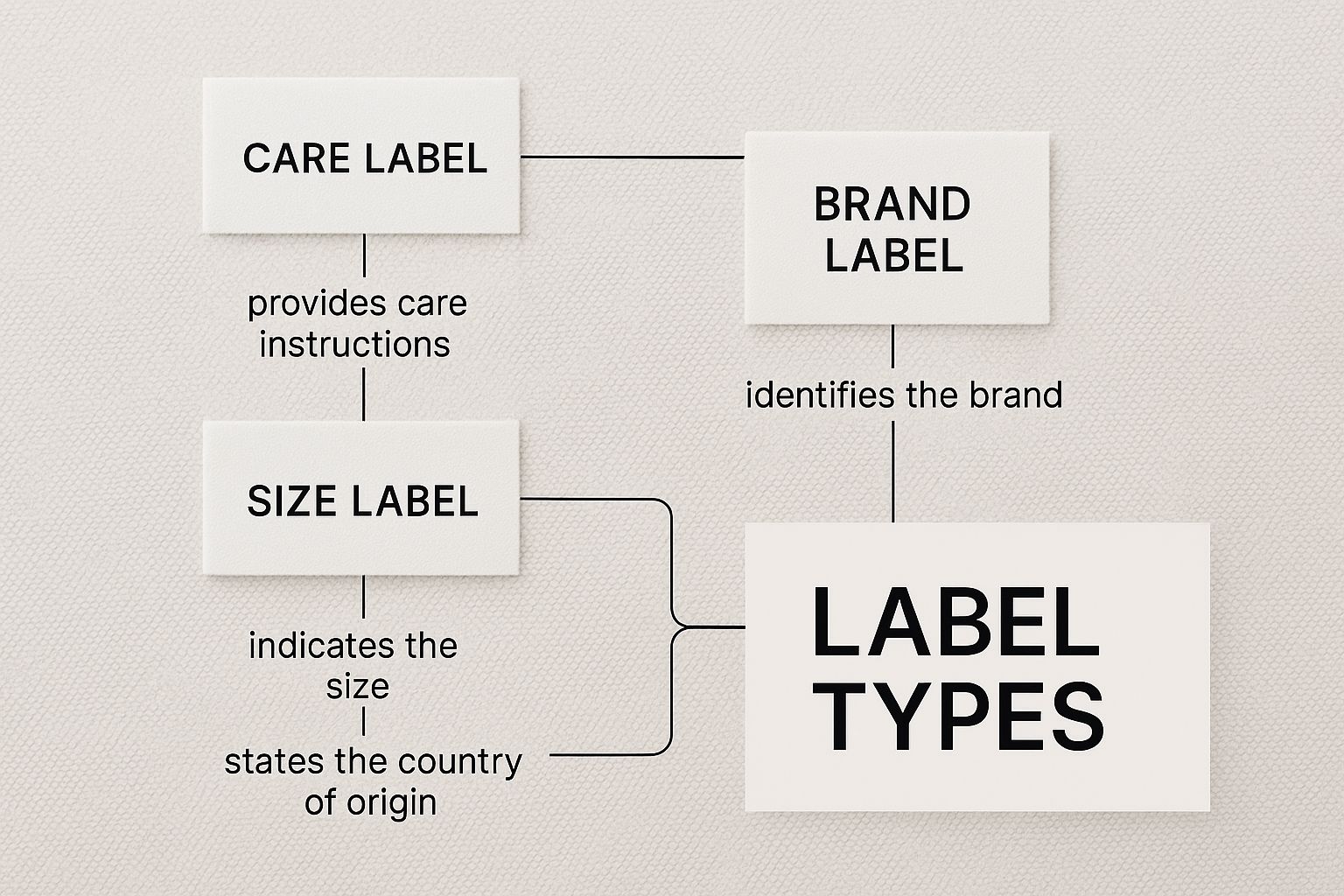

This guide will walk you through the whole process. We will look into the three main types of labels and what they are used for, so you can figure out which one fits your products and what your brand stands for. Getting to grips with the world of clothing labels printing is a fundamental part of building a successful apparel line.

To get you started, we have organised this guide to build your knowledge from the ground up. You will learn about:

A label is a silent ambassador for your brand. It communicates quality, care, and identity, playing a significant role in how customers perceive your products. Choosing the right one is a decision that supports your entire brand story.

For a deeper look into the specifics of what is involved, you can learn more about label printing for clothing and how it impacts brand presentation.

To make the choice a bit easier, the table below gives you a quick comparison of the main label types. It highlights their look and feel, how long they last, and what they are best used for in the fashion world. This should help you quickly see which option might be the best starting point for your brand.

| Label Type | Look and Feel | Durability Level | Ideal For |

|---|---|---|---|

| Woven Labels | Premium, textured, and high-end with sharp detail. | Very High | Outerwear, denim, luxury goods, and items requiring long-lasting branding. |

| Printed Labels | Smooth and soft, allowing for complex graphics and gradients. | Medium | T-shirts, baby clothes, lingerie, and items where comfort is key. |

| Heat Transfer | Tag-less, completely flat, and soft against the skin. | Moderate | Activewear, sportswear, children’s clothing, and performance apparel. |

Each type has its place, and the best choice depends on the garment itself and the message you want to send. A tough woven label feels right on a heavy coat, while a soft, tag-less transfer is perfect for a running top.

Picking the right method for your clothing label printing is one of those foundational decisions that shapes your brand’s look, feel, and even its lifespan. You have got three main players on the field: woven, printed, and heat transfer labels. Each one has its own strengths, and knowing the difference is key to matching your label to your garment and your customer’s expectations.

This isn’t just a technical choice; it’s a branding one. A luxurious cashmere jumper calls for a different kind of label than a high-performance running top. Let’s look into these three popular methods to figure out which one is the right fit for your clothing line.

The image below gives you a quick visual snapshot of the different label types available, showing how they look on the fabric.

As you can see, the visual differences are stark. From the rich, detailed texture of a woven label to the smooth, seamless finish of a tag-less one, each creates a completely unique impression.

When you want to communicate quality and durability, woven labels are the gold standard. Think of them less as something printed on a tag and more as a tiny piece of textile art. The design isn’t ink on a surface; it’s woven together from threads on a loom, making your branding an integral part of the fabric itself.

This construction makes them incredibly tough. They will not fade or peel off, no matter how many times they go through the wash. This makes them the perfect match for items built to last, like outerwear, denim, and premium garments. The texture and depth of a woven label convey a sense of craftsmanship that customers can both see and feel.

You’ll generally come across two main types of weaves:

Woven labels are your brand’s permanent signature on a garment. Their longevity and premium feel are an investment in quality perception, reinforcing the value of the product itself.

Printed labels are your go-to when your design is full of complex graphics, colour gradients, or a whole rainbow of shades. Unlike woven labels, here the design is printed directly onto a base material like satin, cotton, or polyester. It is a lot like printing on paper, which opens the door to photorealistic images and tiny details that would be a real challenge to weave.

Their biggest strength is their versatility. If your brand has a colourful, detailed logo, a printed label can replicate it perfectly. They are also typically very soft and smooth to the touch, making them a comfortable choice for items worn close to the skin, such as t-shirts, baby clothes, and underwear.

The most common materials you will see for printed labels are:

While incredibly versatile, printed labels are generally less durable than their woven cousins. Over many wash cycles, the ink can start to fade, particularly if you’re using lower-quality materials.

Heat transfer labels, often called tag-less labels, are the undisputed champion of comfort. These labels are first printed onto special transfer paper and then applied straight onto the garment fabric using a heat press. What you get is a completely flat, seamless design with no scratchy edges or sewn-in tags to speak of.

This makes them the obvious choice for any clothing where potential irritation is a no-go. Think activewear, sportswear, children’s clothing, and undergarments. For an athlete focused on performance or anyone with sensitive skin, a tag-less label completely removes a common source of discomfort.

The application is straightforward, and the finish is clean and professional. They are fantastic for displaying logos, sizing, and basic care instructions right on the inside of the garment. While they hold up very well to everyday wear and washing, be aware that extremely high heat from a tumble dryer or iron can sometimes damage the transfer. For most uses, they perform brilliantly and offer an unbeatable level of comfort for the wearer.

The material you choose for your clothing label does far more than just carry your brand name. It’s often the first physical touchpoint a customer has with your garment, sending a powerful, unspoken message about its quality and your brand’s ethos. This makes picking the right fabric a crucial step in the clothing labels printing process.

Think about it: a scratchy, rigid label on a soft cashmere jumper immediately creates a jarring experience. It’s a disconnect. But a smooth, supple tag reinforces the garment’s premium feel. Getting this small detail right is about making sure every part of your product tells a consistent story of quality and care.

Your label material should be a direct extension of your brand identity. A company known for rugged, all-weather outdoor gear would not use the same delicate satin as a high-end lingerie line. The material has to be fit for purpose, matching not just the brand but also the garment’s intended use.

Put yourself in your customer’s shoes. If you’re designing clothes for babies, softness and hypoallergenic properties are non-negotiable. For heavy-duty workwear, you need something that can stand up to industrial washing cycles without a second thought. Matching the material to its function is everything.

Here is a quick rundown of the most popular choices you’ll encounter:

A label’s material is a tactile handshake with your customer. A brand that crafts organic baby clothes will naturally lean towards soft, hypoallergenic cotton to reinforce its promise of comfort and safety. In contrast, a company producing durable workwear needs the resilience of polyester to back up its claims of toughness.

When you’re choosing a material, you’re balancing two things: how it feels against the skin and how well it will last. These qualities often sit at opposite ends of a spectrum, and your perfect choice depends entirely on the garment’s job.

Satin, for instance, feels wonderful but might not be the best candidate for an item destined for heavy-duty washing. Its smooth surface is fantastic for printed labels that require fine detail, but its delicate fibres need a bit of care.

Polyester is built to endure. It can handle high-temperature washes and resists fading, which is why it is a practical default for uniforms, sportswear, and kids’ school clothes. The trade-off is that its texture can be slightly coarser, so it is often used on items where the label will not have prolonged, direct contact with sensitive skin.

If you are looking for a wider overview of material choices that go beyond just clothing, you might find our guide on the best materials for labels for all sorts of products helpful.

To nail down your choice, think about the product’s entire lifecycle. How will it be worn, used, and cared for? A label on a swimsuit has to withstand chlorine and saltwater. A label on a fine silk blouse must be delicate enough not to pucker the fabric.

This simple table can help you compare your options at a glance:

| Material | Key Strengths | Best For | Considerations |

|---|---|---|---|

| Satin | Luxurious feel, smooth finish | High-end fashion, lingerie, formalwear | Can be less durable in harsh washes |

| Cotton | Soft, natural, eco-friendly | Organic apparel, baby clothes, casual tees | Can fray more easily than synthetics |

| Polyester | Extremely durable, colourfast | Workwear, sportswear, outerwear, uniforms | Can feel less soft against the skin |

| Taffeta | Crisp, stable, economical | General apparel, care labels, information tags | A basic option without a premium feel |

Your material choice is a small but mighty part of the clothing labels printing journey. It is a detail that bridges the gap between a simple product and a memorable brand experience, helping you build a stronger, more tangible connection with your customers.

Think of a clothing label as more than just a legal necessity. It’s a tiny piece of brand real estate, a chance to speak directly to your customer about quality, identity, and the care you put into your work. An effective design in clothing labels printing can turn a simple tag into a powerful marketing tool, making your product memorable long after it leaves the shop.

A great label design strikes that perfect balance between providing information and being visually appealing. It should feel like a natural part of the garment, not just a tacked-on afterthought. From the typeface you choose to the colours you use, every element plays a part in creating a label that gets noticed for all the right reasons.

The font you select for your label does more than just spell out words; it sets a tone and projects a personality. A beautiful, ornate script might look fantastic on a computer screen, but it could become an illegible smudge when scaled down to fit on a tiny woven label.

Keep these points in mind when you are picking a font:

Colour is a powerful tool. It can instantly set a mood, grab attention, and make your label pop against the garment’s fabric. When you’re dealing with clothing labels printing, your colour choices need to be both aesthetically pleasing and practical.

High contrast is your best friend. A dark font on a light background (or vice versa) is the simplest way to guarantee your text is easy to read. A low-contrast design might look subtle and artistic, but it will only frustrate customers trying to find the sizing or washing instructions.

As you think about your label’s design, it helps to understand what makes for the best logo designs for a clothing brand, since your logo will be the main visual feature. The colours in your logo need to work in harmony with your chosen label background and, of course, the garment itself.

Your logo is the star of the show, but its placement has to be strategic. You want it to be prominent without overshadowing the other details. For a standard rectangular label, the logo often looks best centred at the top or positioned neatly to one side.

The size of your logo and the label itself should always be in proportion to the garment. A massive, chunky label on a delicate silk blouse would look completely out of place, just as a tiny, discreet label might get lost on a thick winter coat. Always consider the scale of the garment when you’re finalising your label dimensions.

Beyond all the creative elements, your clothing label must include specific information to comply with regulations. Getting this wrong can lead to real problems down the line, so it is good to get it right from the very beginning.

In the UK, your label must include:

For brands wanting to build a strong foundation, digging into some tips on https://sessionsuk.com/how-to-create-effective-labels/ can offer some valuable extra insight. This stage is about blending legal compliance with a design that supports your brand, turning a simple necessity into a genuine asset.

Digital printing has completely changed the game for apparel branding and the wider clothing market. If you’ve ever wondered how small brands can offer such a range of detailed, multi-coloured designs, the answer is often digital. Technologies like Direct-to-Garment (DTG) printing have made it possible to create stunning, complex graphics without the high setup costs and long lead times of old-school methods like screen printing. It is more than a technical upgrade; it is a direct answer to what modern shoppers want.

Today’s market is all about individuality and getting things fast. Customers are no longer content with mass-produced items; they want personalised clothes that reflect their style. Digital printing is perfectly built for this, enabling quick turnarounds on small, custom orders. This has fuelled the explosive growth of e-commerce and print-on-demand businesses. For a startup brand, being able to print just one T-shirt to test a new design is a massive advantage.

Not so long ago, launching a clothing line meant committing to large minimum order quantities (MOQs) to make it affordable. This was a huge financial risk, especially for new designers. Digital printing, and DTG in particular, smashes that barrier. It makes one-off prints and small batches profitable, opening the door for a new generation of creators.

This flexibility supports a much smarter business model where products are only made after a customer has placed an order. Think about it: no more guessing how many of each size to stock, no more money tied up in inventory, and far less waste. For brands that champion sustainability, this is a huge win. To really make this work for your brand, you need a solid visual identity. It’s worth taking the time to get clear on the difference when understanding branding vs logo, as your label is a direct reflection of this.

The shift towards digital clothing labels printing isn’t just anecdotal; the numbers tell a compelling story. The UK’s direct-to-garment (DTG) printing market, a core component of this trend, was valued at approximately USD 130.8 million in 2024. Experts project it will surge to USD 274.0 million by 2030, which shows just how strong the demand is for high-quality, customised fabric printing. In 2024, the technique known as multi-pass printing, which creates incredibly detailed images, led the way in generating revenue. You can find more detail on these UK market projections on grandviewresearch.com.

Digital printing gives brands the agility to jump on micro-trends and respond to customer feedback almost instantly. A design that takes off on social media today can be printed and shipped out tomorrow- a pace that traditional manufacturing simply can’t keep up with.

This is not just about being fast; it is about staying relevant. This rapid production cycle allows brands to offer a virtually endless catalogue of designs without holding any physical stock, completely changing the financial model of fashion retail. As you explore these newer production methods, it is a good idea to keep an eye on the bigger picture. In fact, you might find our guide on the importance of the labelling industry moving into 2025 useful for understanding these broader industry shifts.

Alright, you’ve got a fantastic design. Now comes the exciting part: turning that digital file into a real, tangible label that you can hold in your hand. This is where the rubber meets the road, involving everything from production logistics to navigating the necessary legal requirements. Getting this stage right is what separates the pros from the amateurs, making sure your brand’s reputation for quality shines through from the factory all the way to the customer’s wardrobe.

The first step is always finding the right printing partner. You need someone who knows their stuff, a supplier with a proven track record in the specific type of label you have chosen- be it woven, screen-printed, or heat transfer. Do not be shy; ask for samples of their previous work. Really feel them. And always check their minimum order quantities (MOQs) to make sure they’re a good fit for your production scale.

Before you give the green light for thousands of labels, you absolutely must sign off on a proof. This is a pre-production sample of your exact label, and it is your last line of defence against costly mistakes.

Go over it with a fine-tooth comb. Check every detail: Are the colours spot-on? Is every word spelt correctly? Is the logo placed exactly where you want it? Once you approve that proof, any errors are on you, and that can mean expensive reprints and frustrating delays.

A good supplier will have a solid, clear approval process. Typically, you’ll see a digital mock-up first, followed by a physical sample for that final, crucial sign-off. This two-step method is a hallmark of professionalism and makes sure everyone is on the same page.

The wider UK printing industry, which includes services like clothing labels printing, is currently navigating some economic shifts. Although overall industry revenue is expected to reach an estimated £9.2 billion by 2025 after a slight dip, specialist sectors are holding strong. This tells us that there’s real stability in focused, high-quality services, especially for premium apparel brands. You can find more detail on the UK printing sector on ibisworld.com.

Compliance isn’t just a box to tick; it’s non-negotiable. In the UK, clothing labels are governed by some very specific rules designed to protect consumers and keep things transparent. Getting this wrong can land you in legal hot water and seriously tarnish your brand’s reputation.

The big one you need to know is the Textile Products (Labelling and Fibre Composition) Regulations. This legislation requires that any garment sold in the UK must have a label accurately listing its fibre content. The fibres have to be listed by percentage, in descending order of their weight.

For example, you can’t just say “Cotton/Polyester Blend.” The label has to be specific: “80% Cotton, 20% Polyester.” Precision is everything here, as getting it wrong can lead to serious issues with trading standards.

Beyond the legal must-haves, there are a few other things you should include on your labels to meet customer expectations and industry standards:

By carefully managing these production and compliance details, you’ll sidestep the common pitfalls that trip up so many new brands. A smooth production run and fully compliant labelling set the stage for a successful launch, building trust with your customers from the moment they pick up your product.

Even with a good grasp of the basics, a few practical questions always seem to pop up when you’re getting started with clothing labels. Let’s tackle some of the most common ones that new and growing brands often ask.

Hands down, woven labels are the toughest. High-density damask woven labels are built to last.

Think of it this way: the design isn’t just printed on top; it’s woven into the fabric of the label itself. This means your branding and care info will not fade, crack, or wash away, no matter how many times the garment is worn and laundered. This makes them perfect for hard-wearing items like denim, outerwear, and workwear.

This comes down to three things: your brand’s image, your budget, and the type of garment you’re labelling.

Printed labels are also a great choice if you need a cost-effective way to produce eye-catching, detailed designs. It’s a huge market; the UK custom T-shirt printing sector alone was valued at £256 million in 2023 and is expected to grow to £434 million by 2032. You can dig deeper into the growth of the UK custom T-shirt market on this Credence Research report.

The choice between woven and printed is a classic trade-off. Woven labels give you unmatched durability and a high-end feel, while printed labels offer more freedom for complex, colourful designs.

Yes, absolutely. Any clothing sold in the UK must comply with the Textile Products (Labelling and Fibre Composition) Regulations.

At a minimum, this means your label must clearly and accurately state the fibre content- for example, “100% Cotton” or “80% Wool, 20% Nylon”. While care instructions aren’t technically required by law, they are a firm industry standard and something customers definitely expect to see.

When you’re ready to move beyond applying labels by hand, Sessions UK offers a complete range of labelling machinery to streamline your process. Whether you need an entry-level system for small batches or a fully automatic labeller for high-volume production, we have the right equipment to boost your efficiency and give your products that professional finish. Explore the options at Sessions UK.

Copyright © 2026 Sessions Label Solutions Ltd.