Food label printers are specialised pieces of equipment. They print all the crucial information your customers need-from ingredients and allergens to expiry dates and barcodes-directly onto the labels that go on your food and beverage products.

Getting the right printer technology is one of the most fundamental choices you’ll make. It has a knock-on effect on just about everything, influencing your production speed, the cost of each label you print, and your ability to stay compliant with food safety regulations.

Choosing the right food label printer is a cornerstone decision for any food and beverage business, shaping everything from your production line’s efficiency to your regulatory standing. Think of it like picking the right tool for a job; you wouldn’t use a hammer to drive a screw. The best printer is the one that fits your specific needs perfectly.

For example, a small artisan bakery making fresh sandwiches with a two-day shelf life has completely different labelling needs than a large-scale manufacturer producing frozen meals. The baker might just need a fast, simple printer for ‘best before’ dates, whereas the manufacturer needs labels that can survive months in a freezer without smudging or fading. The first step to making a smart investment is to get to grips with the core technologies available.

When you start looking at food label printers, you’ll find three main technologies dominate the market: direct thermal, thermal transfer, and inkjet. Each comes with its own distinct advantages and disadvantages, especially when used in a food production environment.

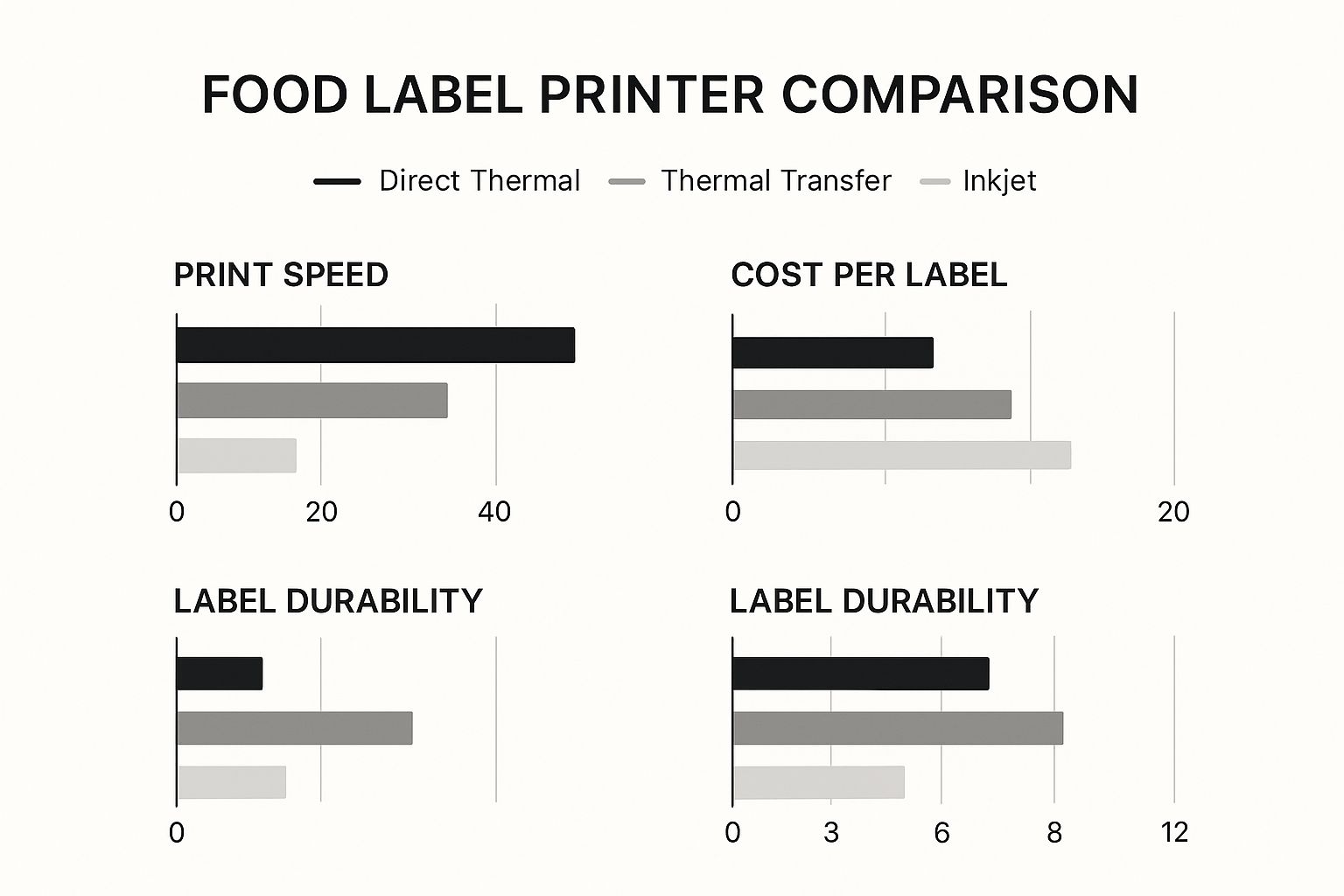

To help you see the differences at a glance, here’s a quick breakdown of how these technologies stack up.

This table gives a bird’s-eye view of the key trade-offs between the most common printer technologies for food labelling.

| Printer Technology | Best For | Durability | Cost Per Label |

|---|---|---|---|

| Direct Thermal | Short-life labels (e.g., shipping, receipts) | Low (fades with heat/light) | Low |

| Thermal Transfer | Long-life product labels (e.g., frozen food) | High (resists moisture, heat, friction) | Medium |

| Inkjet | Full-colour, high-quality branding | Varies (depends on ink/label material) | High |

There is a clear balance to be struck between performance and cost, with each technology serving a different purpose.

This market is seeing some serious growth. Projections show the label printer market expanding from around USD 553.9 million in 2025 to USD 836.4 million by 2035. Thermal printing technology already commands over 45% of the market share, largely because it hits that sweet spot of affordability and high-resolution printing that food information labels demand.

You can explore the different label printer machine UK options to see what might fit your setup.

When you’re putting together or upgrading your commercial kitchen, make sure your ultimate restaurant kitchen equipment list includes a dedicated and reliable food label printer. It’s as much an asset as your ovens and fridges for maintaining an efficient and compliant operation.

To pick the right food label printer, you first need to get your head around the core technologies that make them tick. It’s a bit like choosing the right engine for a car-the decision you make on thermal, inkjet, or laser printing will have a massive knock-on effect on your label’s durability, print speed, and day-to-day running costs.

There’s no single “best” option. Each technology shines in different food production settings. The machine that’s perfect for churning out simple, short-life date codes is a completely different beast from one designed to produce eye-catching, full-colour labels destined for a competitive retail shelf.

Walk into almost any food production facility, and you’ll find thermal printers. There’s a good reason for this. They are incredibly reliable, fast, and built to withstand the pressures of a busy line. They come in two main flavours: direct thermal and thermal transfer.

A direct thermal printer is simplicity itself. It uses a heated printhead to activate a special coating on the label paper, creating the text or image. There’s no ink, toner, or ribbon involved, which makes them cheap to run and easy to maintain. This makes them a go-to for things like shipping labels, till receipts, and fresh food items that will be sold and used quickly. The trade-off? The labels can fade over time, especially if they get warm or are left in direct sunlight.

Thermal transfer printers take a different approach. They use a heated printhead to melt a wax or resin-based ink from a ribbon directly onto the label’s surface. This process creates an incredibly tough, smudge-proof, and long-lasting print that can stand up to moisture, chemicals, and rough handling. This inherent toughness makes thermal transfer the clear winner for most product labels, particularly for anything that will be refrigerated, frozen, or handled constantly.

For products with a long shelf life or those facing harsh conditions like freezers and condensation, thermal transfer printing is the only reliable choice. Its ability to create durable, scannable barcodes and legible text protects both your brand and your supply chain integrity.

When your label is a core part of your brand and marketing, you need it to look the part. This is where inkjet and laser printers come into their own, producing high-resolution, full-colour labels that can grab a shopper’s attention on a crowded supermarket shelf.

Inkjet printers work by spraying microscopic droplets of ink onto the label, creating vivid, photo-quality images perfect for premium products. Laser printers use heat to fuse a fine powder called toner onto the label, resulting in incredibly sharp text and graphics that won’t smudge. While both are fantastic for producing professional-looking labels in a more controlled, office-type environment, they are less common on high-volume, fast-paced food production lines.

The printer is only half the battle; the label material you choose is just as critical. The material, or “face stock,” has to work with your printer and survive your product’s entire journey-from your production line, through the supply chain, and into your customer’s hands.

Let’s talk about the glue. The adhesive is what makes the label stick, and choosing the wrong one can be disastrous. A label that falls off in a freezer or one that can’t be removed cleanly when needed can cause real headaches.

There are three main types of adhesive:

Choosing a new food label printer can feel a bit like trying to read a foreign language. The spec sheet is often a wall of acronyms and numbers, but getting your head around these technical details is what separates a smart purchase from a source of daily frustration.

Think of it like buying a car. You wouldn’t just look at the colour, would you? You’d check the engine size, fuel efficiency, and boot space to make sure it fits your life. It’s the exact same principle with printers. The specifications tell you the real story of how a machine will perform on your production line-from how fast it can spit out labels during a busy run to how clearly it can print the tiny text on your ingredients list.

One of the first specs you’ll bump into is print resolution, measured in dots per inch (DPI). This number simply tells you how many tiny dots of ink or heat the printer can fit into a one-inch line. The more dots, the higher the DPI, and the sharper and clearer your final label will be.

For food labels, this isn’t just about aesthetics; it’s about compliance. Ingredient lists, allergen warnings, and nutritional panels all use small fonts. A low-resolution printer can turn that critical text into a blurry mess, potentially leading to issues with trading standards or, worse, putting a customer at risk.

For the vast majority of food businesses, a 300 DPI printer strikes the perfect balance between cost and quality. It delivers the clarity you need for compliant, scannable labels without the price tag of a 600 DPI machine.

Another headline figure you’ll see is print speed, which is usually measured in inches per second (IPS). So, a printer rated at 8 IPS can produce an eight-inch-long strip of labels every second. Simple enough.

But here’s the catch: while faster sounds better, especially for high-volume producers, there’s always a trade-off. Pushing a printer to its maximum speed can sometimes slightly soften the print quality. For intricate labels packed with small fonts or graphics, you might find you get the best results by dialling the speed back a notch.

The real trick is to choose a printer with a top speed that comfortably outpaces your current needs. That way, you have room to grow and you aren’t running the machine at its absolute limit all day, every day.

Beyond resolution and speed, a few other specifications will make or break how well a printer slots into your workflow.

Maximum Print Width

This is simply the widest label the printer can physically handle. It’s a hard limit, so it’s crucial to pick a printer that can accommodate the biggest label you use, or might use in the future. Most industrial food label printers come in standard sizes, typically 4 inches or 6 inches.

Connectivity Options

How will the printer talk to your computers?

By digging into these core specifications, you can cut through the marketing fluff and get a clear picture of how a printer will work for your business. This knowledge helps you compare models properly and invest in a machine that will be a reliable asset for years to come.

Let’s be clear: getting your food labels right in the UK isn’t just good practice; it’s a legal necessity. In this heavily regulated world, your food label printer isn’t just another piece of equipment. It’s your frontline tool for staying compliant and keeping your customers safe.

Getting it wrong can bring serious legal headaches and can quickly tarnish a brand reputation you’ve worked hard to build. A capable printer is the heart of producing labels that are accurate, clear, and perfectly legible-all core tenets of UK food law.

When we talk about food labelling laws, two major pieces of legislation shape what you need to do. The first is the Food Information to Consumers (FIC) regulation. Think of this as the rulebook for all food information, covering everything from mandatory nutritional declarations to details about the product’s origin.

The second is Natasha’s Law, a more recent and crucial update. It focuses squarely on foods that are pre-packaged for direct sale (PPDS). This law mandates a full ingredients list, making sure any of the 14 major allergens are highlighted. It closed a dangerous loophole and made accurate, on-demand printing necessary. To get a fuller picture of what’s expected, our guide on https://sessionsuk.com/understanding-label-regulations-2025-guide-production-teams/ is a great resource.

A reliable food label printer moves from being a ‘nice-to-have’ to a critical asset. It gives you the control to instantly update labels with allergen information, change ingredient lists, and print compliant use-by dates, mitigating risk with every label produced.

This ability to print on demand is key. Imagine a supplier changes an ingredient, or you tweak a recipe. You can adjust your labels immediately, without being stuck with thousands of pre-printed-and now useless-labels. This kind of agility is exactly what you need to navigate the regulatory landscape.

Beyond ingredients and allergens, regulations demand solid traceability. If a product recall ever becomes necessary, you have to be able to track affected batches through the entire supply chain, and do it fast. This is where barcodes and batch codes prove their worth.

A high-quality food label printer is built to create these unique identifiers with total precision.

This function is so fundamental that the UK barcode printer market is set for major growth. Projections show a compound annual growth rate of 5.8% between 2025 and 2035, a trend fuelled by the ever-growing need for seamless traceability in stores and online.

Putting your money into the right food label printer is a proactive investment in your business’s health. It gives you the power to meet complex legal standards head-on, drastically cutting the risk of expensive mistakes or non-compliance penalties. This is especially true in specialist areas like health foods, where accuracy is everything. For those products, Mastering Supplement Label Requirements is just as important as general food laws.

By making sure every label you produce is clear, correct, and compliant, you’re not just protecting your business. You’re building trust and showing customers that you take their safety as seriously as they do.

A food label printer doesn’t just sit on a desk; it needs to become a part of your daily operations. To get real value from it, the printer has to slot into your production workflow, talking to your software and fitting into your physical line. The aim is to get away from manually typing data and juggling separate processes, and move towards a smart, connected system that prints the right label, for the right product, at precisely the right moment.

Think of this integration as more than just plugging in a cable. It’s about creating a smooth channel for information to flow from your central product database straight to the printer. This connection is your best defence against human error-like someone mistyping an expiry date or ingredient list, a simple mistake that can lead to expensive recalls and compliance headaches.

The push towards smarter labelling is clear. The UK label printer market is growing steadily, largely driven by the food and beverage industry’s need for better automation and traceability. As businesses digitise their processes to improve efficiency and meet strict regulations, integrated printing becomes part of the process. You can find more on this trend in the latest research on the UK label printer market from 6wresearch.com.

Your software is the command centre for your entire labelling process. Modern label design software is far more than a simple design tool for arranging text and images; it’s the link between your product information and the printer itself.

Imagine you have a master spreadsheet or database holding all your crucial product details-names, weights, ingredients, barcodes, prices, you name it. Instead of an operator manually re-typing this information onto a label template for every single batch, the software can pull it in automatically. When it’s time to print labels for your “Organic Strawberry Jam,” the system simply grabs the correct, pre-approved information. This eliminates guesswork and removes the risk of costly mistakes, forming the foundation of a reliable labelling system.

By linking your printer to a central database, you create a single source of truth for your product information. This drastically reduces the chance of labelling errors and makes updating information across your entire product range a simple, one-time task.

How a printer physically fits into your production line is all about your scale and speed. There’s no one-size-fits-all answer here. The right setup for a small artisan producer will look completely different from what a large-scale manufacturer needs.

A small artisan bakery making a few hundred loaves a day would likely get by perfectly with a standalone tabletop printer. An operator can print labels in batches whenever they’re needed and apply them by hand. It’s a simple, flexible approach that’s ideal for low-volume, high-variety production.

A mid-sized meal-prep company shipping hundreds of orders might upgrade to a semi-automated system. In this scenario, a printer could sit beside a conveyor belt, churning out labels for an operator to apply as products move past. It’s a great way to boost speed without the major investment of a fully automated line. For businesses exploring that middle ground, there are many different labelling solutions to consider.

For a large food manufacturer running high-speed lines, a fully automated print-and-apply system is the gold standard. These machines are built directly into the production line. They automatically print a unique label for each product and apply it with pinpoint accuracy as it speeds down the conveyor, all without a human touching it. You’ll also find mobile printers are invaluable for warehouse tasks, letting staff print new shelf-edge labels or update stock information on the spot.

This table gives a clearer picture of how different businesses can tackle integration.

| Business Scale | Typical Setup | Software Integration | Primary Benefit |

|---|---|---|---|

| Small Bakery | Standalone tabletop printer | Basic label software with manual data entry | Low initial cost and high flexibility for small batches. |

| Meal-Prep Company | Semi-automated printer at a packing station | Software linked to order management system | Increased speed and accuracy over manual methods. |

| Large Manufacturer | Fully automated print-and-apply system | ERP integration for real-time data pulls | Maximum speed, accuracy, and labour efficiency. |

The goal is to find a setup that doesn’t just work, but actively makes your production process smoother, faster, and more reliable, no matter the size of your business.

Stepping into the world of food label printers can feel overwhelming. There are a lot of options, and it’s not always obvious which one fits your specific production needs. To help clear things up, I’ve put together answers to the questions I hear most often from producers.

The main difference comes down to how they get the image onto the label. Think of it this way:

Direct thermal printers work with special, heat-sensitive paper. The printhead applies heat directly onto this paper, causing it to turn black and create your text or barcode. It’s a simple process because there’s no ink, toner, or ribbon involved. This makes it a great fit for things with a short shelf life, like shipping notices or fresh deli labels, as the print can fade over time with exposure to heat or light.

Thermal transfer printers use a ribbon coated in wax or resin. The printhead heats the ribbon, which then melts the ink onto the label’s surface. This creates a far more durable and long-lasting image that stands up to scratches, moisture, and temperature changes. For most food products that need to survive in a fridge, freezer, or a busy kitchen, thermal transfer is the way to go.

The resolution you need-measured in dots per inch, or DPI-really depends on what you’re printing on your label.

A 203 DPI printer is often perfectly fine for basic text and large, simple barcodes. If you’re just printing straightforward shipping information, it’ll do the job without any fuss.

For most food packaging, a 300 DPI printer is what I’d recommend. It delivers the sharpness needed for tiny text in ingredient lists and ensures that compact 2D barcodes scan reliably every time, which is necessary for traceability. A higher 600 DPI resolution is usually overkill for food, reserved for tiny, complex labels you might find on electronics or cosmetics.

Most industrial food label printers, particularly thermal models, are workhorses built for single-colour printing-usually black. Their strength lies in speed, durability, and cost-effectively printing variable data like best-before dates and batch codes.

If you need full-colour labels that show off your branding, you’ll be looking at an inkjet label printer. Many businesses find a two-step process works best: they order professionally pre-printed colour labels and then use an in-house thermal transfer printer to add the black, variable information on demand.

Keeping your printer in good shape is surprisingly simple, but it makes a huge difference to print quality and the machine’s lifespan. The two key tasks are cleaning the printhead and the platen roller.

Doing these quick checks regularly will save you from bigger headaches down the road. To sidestep other potential issues, you might read up on the common mistakes when applying labels.

For expert advice on choosing and maintaining the right food label printer for your business, contact Sessions UK. Find the perfect solution for your production needs at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.