A food label printer is not just another piece of office equipment. It’s a specialised tool built to produce clear, long-lasting, and legally compliant labels for everything you sell, from sandwiches to sauces. Think of it as the final, critical step in your production line, responsible for printing information like ingredients, allergens, and best-before dates right onto your packaging.

Getting this right is non-negotiable. The right printer helps your business meet all legal standards and keeps your brand looking its best on every single item.

Choosing a food label printer is a big decision for any food business, whether you’re a small artisan bakery or a large-scale manufacturing plant. Those little labels on your products do so much more than just identify what’s inside- they’re a direct reflection of your commitment to quality and transparency. A smudged, faded, or peeling label does not just look unprofessional; it can make crucial information unreadable and seriously erode customer trust.

The challenge runs deeper than just looking good. Food labelling is a field of strict legal standards that dictate exactly what information must be displayed and how legible it has to be. The printer you choose directly affects your ability to hit these targets consistently. It all comes down to a mix of print durability, speed, and whether the machine can handle the specific materials your packaging requires.

Different businesses have vastly different labelling needs. A local café selling pre-packed sandwiches needs a straightforward, on-demand solution for short runs. A factory producing thousands of products an hour requires a high-speed, automated workhorse integrated into its production line.

Understanding the main types of food label printers is the first step toward finding the perfect match for your operation.

This need for specialised solutions is fuelling the growth of the UK label printer market, driven largely by the food and beverage industry. As businesses embrace automation, they’re looking for printers that can boost productivity while navigating the complex web of product safety and traceability rules. UK government regulations are also pushing for greater labelling accuracy and sustainability, which is why we’re seeing a shift towards more eco-friendly printing technologies. You can dig deeper into these trends by exploring the latest UK label printer market research.

Think of your printer as an investment in both operational efficiency and brand integrity. It’s what guarantees every product leaving your facility is presented professionally and meets all legal guidelines, protecting your customers and your business.

Choosing the right printing technology for your food labels is a lot like picking the right tool for a kitchen job. You wouldn’t use a delicate paring knife to chop through a tough butternut squash, would you? In the same way, the printing method you select needs to match the specific demands of your product and its journey from your facility to the customer’s home.

The two main contenders in the food labelling world are direct thermal and thermal transfer printing. They both use heat to create an image, but the way they go about it is completely different. Understanding this difference is the first step to making a smart investment.

Direct thermal printing is as straightforward as it gets. The printer’s printhead applies heat directly onto a special, chemically coated label material, which turns black in the heated areas. If you’ve ever looked closely at a supermarket deli receipt, you’ve seen direct thermal printing in action. No ink, no toner, no ribbon- just heat and paper.

This simplicity makes it a very cost-effective option for short-term applications. The catch? The labels are sensitive to heat and light, meaning they will fade over time. They’re perfect for products that fly off the shelves.

Thermal transfer printing is the heavy-duty alternative. Instead of heating the label itself, the printhead heats a separate wax or resin ribbon. This melts the ribbon’s ink onto the label material, creating a permanent, smudge-proof bond. It’s a bit like using a hot stamp to create an image that’s there for good.

This process results in incredibly tough labels. They can handle moisture, friction, extreme temperatures, and UV exposure without breaking a sweat. While you do have the ongoing cost of ribbons, the durability is non-negotiable for many food products, especially those with a long shelf life or that live in a fridge or freezer. To see this technology in action, you can explore a variety of commercial food label printer options.

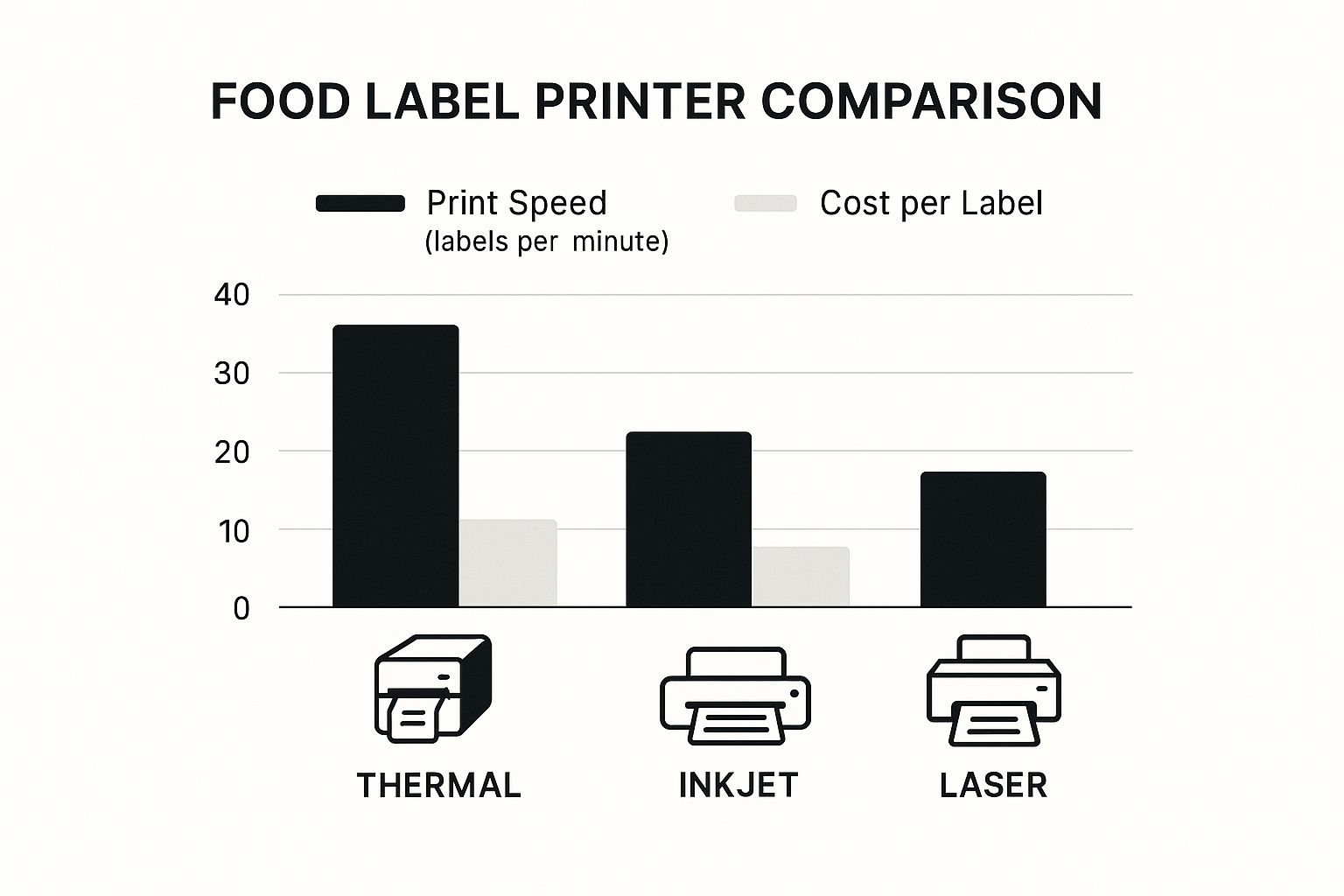

As you can see, thermal printers hit the sweet spot, offering a great combination of speed and a lower cost for every label you print.

It’s no surprise that the demand for these reliable printing solutions is on the rise. The global label printer market is expected to hit USD 836.4 million by 2035. Thermal technology is leading the charge, projected to make up over 45% of the market share in 2025. This popularity comes down to its knack for producing the crisp, high-resolution barcodes and text needed for food traceability and safety.

To make sense of the options, it helps to see them side-by-side. Each technology has its strengths and is best suited for different jobs in the food industry.

| Technology | Best For | Durability | Upfront Cost | Cost Per Label |

|---|---|---|---|---|

| Direct Thermal | Short-life products, shipping labels | Low (fades with heat/light) | Low | Very Low |

| Thermal Transfer | Long-life products, frozen goods | High (resists elements) | Medium | Low to Medium |

| Inkjet | Full-colour product labels in small runs | Medium (depends on ink/material) | Low to Medium | High |

| Laser | Sheet-fed, full-colour labels | Medium to High (toner is tough) | Medium to High | Medium |

This table shows that while direct thermal is the budget-friendly choice for speed, thermal transfer offers the resilience needed for most packaged foods. Inkjet and laser step in when branding is the top priority.

While thermal printers are the workhorses of the industry, inkjet and laser printers have carved out their own niches, especially when it comes to creating full-colour labels.

Inkjet printers are brilliant for producing photo-quality labels. They’re often the go-to for small-batch or artisan producers who need their products to have serious shelf appeal. Laser printers deliver incredibly sharp text and graphics, making them a solid choice for printing entire sheets of labels rather than individual ones on a roll.

When you start comparing food label printers, you’ll be hit with a wall of technical jargon. It can feel a bit overwhelming, but understanding these specs is the secret to finding a machine that actually fits your business. Getting it right now saves a world of frustration down the line.

At the heart of it all are three core specifications: print resolution, print speed, and print width. Each one has a massive impact on the quality, efficiency, and flexibility of your labelling. Think of them as the three legs of a stool- get one wrong, and the whole thing wobbles.

Print resolution is measured in dots per inch (DPI). This number tells you how many tiny dots of ink or heat the printer can cram into a one-inch line. More dots mean a sharper, cleaner, and more detailed final print.

Think of it like the difference between a standard TV and a 4K one. The 4K screen has millions more pixels, so the picture is incredibly crisp. It’s the same idea with labels. A basic 203 DPI printer is fine for things like large, simple shipping labels where you just need a readable barcode. For the small text of an ingredients list or a complex 2D barcode, you’ll want the clarity of 300 DPI or even 600 DPI.

Picking the right DPI is a bit of a trade-off. Higher resolution printers can be a bit slower and cost more upfront, so it’s all about matching the printer’s capability to what your labels actually need.

Print speed is measured in inches per second (IPS), which is exactly what it sounds like: how fast the printer spits out labels. A small artisan bakery printing a few dozen labels a day will be perfectly happy with a speed of 4 IPS. If you’re running a high-volume production line, you’ll need an industrial machine that can keep up, often pushing 12 IPS or more.

The maximum print width is another crucial spec. It dictates the widest label the machine can handle. Most printers top out at around 4 inches, which covers the vast majority of food packaging. If you need to print larger labels for big containers or wide promotional stickers, you have to double-check that your chosen printer can accommodate them.

Do not forget to look at the connectivity options. How the printer talks to your computer is a practical detail that makes a big difference.

Figuring out food labelling in the UK is about more than just having a tasty product. It’s a field of regulations, and you’ve got to follow them to the letter. The printer you choose for your food labels plays a surprisingly large role in keeping you compliant. A good machine will produce labels that look professional, but they need to stay readable all the way from your kitchen to the customer’s hands.

It’s not just about the ingredients list. Think about regulations like Natasha’s Law, which requires you to clearly list all allergens on any food that’s pre-packed for direct sale. That puts a huge amount of pressure on businesses to get things right, every single time. A label that smudges or fades isn’t just unprofessional; it’s a serious health hazard that could land you in hot water. Your printer must produce crisp, clear text, even when you’re cramming a lot of information into a tiny space.

UK food laws are very clear: all the mandatory info, like nutritional facts and “use by” dates, has to be easy to read and permanent. This means your labels need to be tough enough to handle whatever is thrown at them.

Just think about the journey your food takes:

For creating tough, long-lasting labels that can handle these challenges, you can’t go wrong with a thermal transfer printer. Pairing it with a resin ribbon and a synthetic label material is often the gold-standard combination.

The printer is only one part of the picture. You also need to be on top of the wider rules. Following essential food safety guidelines for restaurants often shapes what information you have to put on your labels in the first place, which brings you right back to needing a reliable printing setup.

Being able to trace your products is another non-negotiable legal requirement. Your labels need to have batch codes or lot numbers so you can track a specific product right through the supply chain. This is your lifeline if you ever have to do a product recall.

This means your food label printer must be able to handle variable data printing without breaking a sweat, letting you print a unique code for every batch without holding up the production line. By integrating your printer with the right food labelling machinery, you can even automate this entire process, which cuts down on human error and boosts your efficiency.

The need for printers that can do all this is fuelling a huge market. The global label printing industry was worth USD 52.11 billion in 2025 and is expected to hit USD 70.53 billion by 2029. The UK is a big part of that growth, driven by our food industry’s strict rules on product information and safety.

Even the most advanced food label printer is only as good as the supplies you feed it. The labels and ribbons you choose are just as important as the machine itself, deciding whether your final print is crisp, durable, and fit for purpose. Think of it like cooking- having a fantastic oven means nothing if you use poor-quality ingredients.

The label itself has two key parts: the face stock (the material you print on) and the adhesive (the bit that makes it stick). Getting both right is crucial for creating labels that last all the way from your production line to the customer’s home.

The environment your product will live in is the biggest factor in choosing the right material. A simple paper label might be fine for a dry loaf of bread on a shelf, but it’ll disintegrate on a chilled salad container that’s covered in condensation.

Here’s a quick rundown of your main options:

The adhesive is just as critical. A permanent adhesive creates a powerful bond for information that should never be removed. A removable adhesive is ideal for temporary things like pricing or promotional stickers. For frozen foods, you’ll need a specialised freezer-grade adhesive that keeps its grip even in sub-zero conditions.

If you’re using a thermal transfer printer, picking the right ribbon is the final piece of the puzzle. The ribbon’s makeup determines how durable the printed information will be.

The general rule is simple: the more durable the label material, the more durable the ribbon needs to be. Mismatching them is a recipe for poor print quality and smudging.

There are three main types of ribbons to understand:

Let’s take a real-world example. A pre-packaged salad sold in a plastic tub would need a polypropylene label paired with a wax-resin ribbon. This combination makes sure the label won’t peel off in a chilly, damp fridge and the print won’t smudge from condensation.

For a deeper look into bringing all these elements together, you can explore guides on how to create effective labels. This will help you make choices that align perfectly with both your product and your brand.

Now it’s time to match the right technology to your business. This is where you connect theory to practice. The best food label printer is not a one-size-fits-all solution; it depends entirely on your operational scale and day-to-day reality.

Let’s look at a few real-world scenarios to see how this plays out.

Imagine a small, local bakery. They’re making fresh bread and pastries daily, and their labels just need to last until the customer gets home. A simple, on-demand direct thermal desktop printer is perfect for this. It’s affordable, does not take up much counter space, and is ideal for the low volume of short-life labels they produce.

Now, think about a growing meal prep company. Their needs are a bit more complex. Their labels have to hold up against refrigeration, condensation, and maybe even a trip in the microwave. Here, a thermal transfer desktop printer is a much better fit. Paired with tough polypropylene labels and a wax-resin ribbon, it creates durable, scannable labels that won’t smudge or fade in the cold.

Finally, picture a large-scale food manufacturer with a humming, high-speed production line. They need a true workhorse. An industrial thermal transfer printer is the only real answer here. These machines are built to run non-stop, churning out thousands of compliant, long-lasting labels every single day without breaking a sweat.

Before you commit, take a moment to run through this final checklist. Getting clear on these points will make your decision much easier.

Answering these questions will point you directly to the right category of machine for your operation. If you want to explore specific models and features, our complete guide on the label printing machine for food offers a more detailed breakdown.

Stepping into the world of food label printers can feel a bit overwhelming, so it’s only natural to have a few questions. Let’s clear up some of the most common queries to help you feel confident in picking the right machine for your business.

Think of it like choosing a vehicle. A desktop printer is your reliable city car- compact, efficient, and perfect for smaller jobs. They’re designed for lower print volumes, usually topping out at around 1,000 labels per day, which makes them a great fit for small businesses, cafes, or kitchens where space is at a premium.

An industrial printer is a lorry. It’s built tough, often with a full metal casing, ready to handle the rough-and-tumble environment of a busy warehouse or production floor. These machines are workhorses, built to print thousands of labels day-in and day-out at high speeds, keeping pace with demanding production lines.

In short, not really. Standard thermal printers- whether they’re direct thermal or thermal transfer- are monochrome. They’re fantastic for sharp, black text and barcodes, but they can’t produce the colourful, eye-catching labels you see on shop shelves.

If you need branding, full-colour logos, or product photography on your labels, you’ll need to look at a dedicated colour label printer, which almost always uses inkjet technology. While a few specialised thermal printers can manage a second spot colour on specific paper, it’s no substitute for proper full-colour printing.

Most printers will come bundled with basic label design software right out of the box. This is usually more than enough to get you started, letting you create simple layouts with text, barcodes, and maybe a basic logo. It’s perfect for simple compliance and product identification.

If your needs are a bit more complex- say, you want to pull ingredients from a database, automatically calculate nutritional information, or link up with your weighing scales- you’ll probably want to invest in more powerful, third-party software. These advanced programs can integrate with your other business systems, which is a massive help in cutting down on manual data entry and costly mistakes.

Ready to find the perfect labelling solution for your food products? The expert team at Sessions UK can guide you to the ideal machine for your production needs, ensuring compliance and professional results. Explore our range of labelling machinery at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.