A simple label might seem like a tiny detail, but it is much more than a piece of fabric. It is one of the first things your customer touches and a direct line of communication from you to them. Getting your label printing for clothing right-from brand tags to care instructions-is a fundamental part of the apparel business because it shapes how someone feels about your garment before they even try it on.

Think of a clothing label as your brand’s silent handshake. It is often the first physical clue a customer gets about your product’s quality and the last thing they see when they put it on. More than just a name tag, a good label is a powerful tool for building recognition, sharing information, and meeting legal standards.

A well-designed label instantly signals professionalism and a real eye for detail. It is that finishing touch that separates a thoughtful, established brand from a generic one. For many people, the quality of the label is a direct reflection of the garment’s quality. A cheap, scratchy tag can completely undermine an otherwise fantastic product.

Your label is like a tiny, wearable piece of your brand, sewn directly into your apparel. It carries your logo, your name, and often a hint of your brand’s personality. This constant visual reminder helps customers remember who made their favourite t-shirt or hoodie, encouraging them to come back for more and building genuine loyalty over time.

As you lay the groundwork for your clothing line, knowing how to create a compelling brand identity is absolutely critical. Your label is the physical embodiment of this identity, turning a simple piece of clothing into a full-on branded experience.

A label does more than just state a name; it tells a story. Whether it is through a unique material, a clever design, or a simple, elegant logo, the label is your chance to make a lasting impression.

To get a clearer picture, let’s break down the main types of clothing labels and what they do. Each one has a distinct job to perform.

Key Clothing Label Types and Functions

| Label Type | Primary Function | Common Material | Typical Placement |

|---|---|---|---|

| Brand Label | Purely for identification; features your logo and name. | Woven or Printed Fabric | Centre Neckline or Hem |

| Care & Content Label | Provides legally required information like fibre makeup and wash care. | Satin, Nylon | Inner Side Seam |

| Hang Tag | Marketing and storytelling; offers space for pricing and brand info. | Cardstock, Recycled Paper | Attached with String/Pin |

These core types work together to create a complete and professional presentation for every garment you produce.

Beyond just branding, label printing for clothing is a matter of compliance. Here in the UK, regulations demand that garments display specific information, most importantly the fibre content (e.g., 100% cotton). Skipping this can cause real headaches, especially if you plan to sell through larger retailers.

Labels also offer huge practical value to the customer. Clear care instructions help people look after their purchase, making it last longer and improving their overall satisfaction. A tag that clearly states the size and fit also helps create a positive shopping experience right from the get-go.

Picking the right label is one of the most important decisions you’ll make in the label printing for clothing process. This isn’t just a technical choice; it is about branding. Each label type gives off a completely different vibe, communicating your brand’s personality-whether you’re aiming for premium and traditional, soft and subtle, or bold and informative.

The three main contenders you’ll be weighing up are woven labels, printed labels, and hang tags. Each serves a distinct purpose and suits different garments, budgets, and brand aesthetics. Let’s break them down so you can align your product’s feel with your brand’s core message.

When you think of high-end apparel, you’re probably thinking of a woven label. These are the gold standard. Instead of printing ink onto fabric, the design itself-your logo, your brand name-is literally woven from threads. The result is a beautifully detailed label that is incredibly durable and won’t fade after countless washes.

It is no surprise you see them on designer jackets, premium denim, and quality outerwear. They immediately signal that a garment is built to last. You can even get different weaves, like high-density damask for intricate details or a sturdier taffeta for a more classic look.

While they do have a higher initial cost per piece compared to printed options, the perceived value they add often justifies the investment, especially for brands targeting a premium market.

Printed labels are all about comfort and design flexibility. Here, the branding and care information are printed directly onto a ribbon of material, typically satin, cotton, or nylon. Their biggest selling point? They’re soft. A printed satin label, for example, is far less likely to irritate the skin, making it the perfect choice for lingerie, baby clothes, and t-shirts-anything worn close to the body.

This method also gives you a lot of creative freedom. You can achieve complex, multi-coloured graphics that would be incredibly difficult or costly to replicate with weaving.

A customer who finds a label itchy or uncomfortable will probably just rip it out, and your branding goes with it. A soft, non-intrusive printed label makes sure your brand stays with the garment for its entire life.

They are also generally more cost-effective, particularly for smaller production runs, striking a great balance between quality and budget for emerging brands. If you’re managing production in-house, getting to grips with the equipment is critical; our guide to labels printer machines offers a close look into the solutions available.

Hang tags are your brand’s mini-billboard at the point of sale. While not permanently attached to the garment, they play a massive role in the retail experience. They’re usually made from cardstock or recycled paper but can be crafted from almost anything, including plastic, wood, or even metal.

This is your prime real estate to connect with the customer. Think beyond just a logo. You can share your brand’s story, highlight sustainable materials, give styling tips, or pop a QR code on there that links to your social media. It is a pure marketing opportunity.

To help you weigh it all up, here’s a quick comparison:

| Feature | Woven Labels | Printed Labels | Hang Tags |

|---|---|---|---|

| Best For | Premium branding, outerwear, denim | Intimates, t-shirts, children’s wear | Point-of-sale marketing, brand storytelling |

| Feel | Sturdy, sometimes textured | Soft, smooth, and flexible | Varies by material (typically cardstock) |

| Durability | Highest, will outlast the garment | Good, but can fade over time | Disposable, removed after purchase |

| Cost | Higher per unit | Lower to moderate per unit | Low to moderate, depends on material |

Most brands don’t just pick one. They use a combination: a classic woven label at the neck, a soft printed care label in the side seam, and a creative hang tag for the shop floor. Together, they create a cohesive and professional presentation. Your choice simply comes down to what you want to say and how you want your customer to feel.

Once you’ve settled on the type of label you need, the next big decision is how to actually print it. This is where the magic happens. The printing method you choose isn’t just a technical detail; it shapes the final look, the feel of the label, the cost of each piece, and even how quickly you can get them made. Getting this right is all about matching the technology to your design goals and the scale of your business.

The two main players in the apparel world are screen printing and digital printing. Each has its own personality and is built for different kinds of jobs. Think of it like this: you wouldn’t use a tiny artist’s brush to paint a whole wall, nor would you use a massive paint roller for delicate details. Both tools paint, but you pick the one that fits the task.

Screen printing is a classic, time-tested technique that’s stuck around for a very good reason-it is brilliant for bulk orders. The process is a bit like using a sophisticated stencil. A fine mesh screen is prepared with a negative of your design, and ink is then pushed through the open areas directly onto the label fabric. It is a hands-on method where each colour in your design needs its own dedicated screen.

Because of the initial setup involved in creating these screens, screen printing really shines on large production runs. That setup cost gets spread thin across hundreds or even thousands of labels, making the price per piece incredibly low. It is the go-to choice for brands that need a high volume of identical labels, especially those with simple, bold graphics using just one or two colours. The result is a thick, durable print that sits right on top of the fabric, giving it a distinct and professional feel.

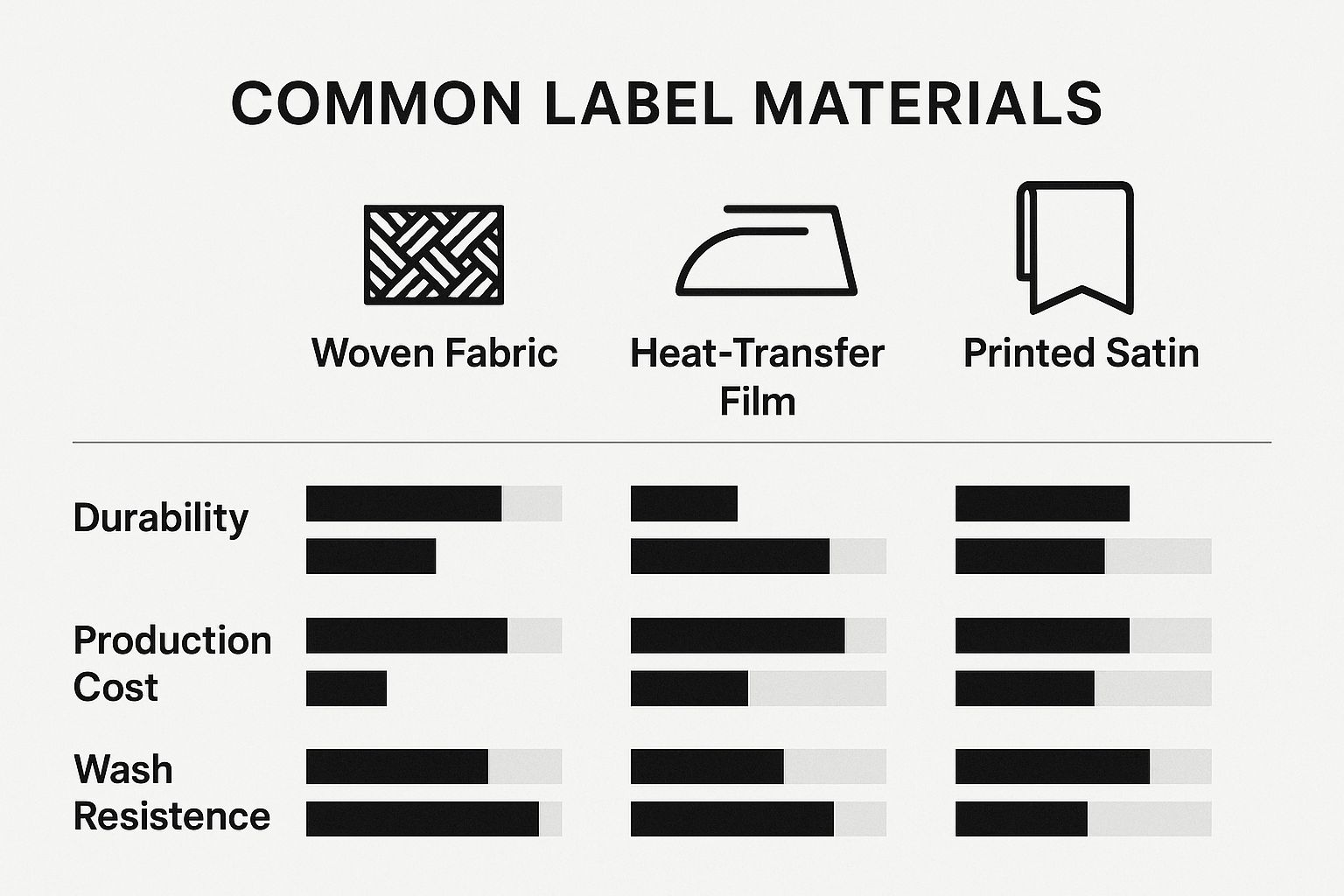

This image gives you a great visual breakdown of how different label materials perform.

You can see that while woven labels are the champions of durability, printed satin strikes a great balance between wash resistance and a more wallet-friendly production cost.

Digital printing is a whole different ball game. It works a lot like your home office printer but on a much more advanced, industrial scale. The printer applies ink directly onto the label material from a digital file, which means you can have an unlimited number of colours and capture incredibly fine details. We’re talking photographic-quality images, smooth colour gradients, and intricate patterns-all perfectly achievable.

The real superpower of digital printing is its flexibility. With no screens to create, it is perfect for small batches, one-off custom designs, or when you’re in a hurry and need a rapid turnaround.

This makes it a fantastic option for startups testing out new products, brands that want to offer personalisation, or for any design that’s rich with multi-tonal graphics. While the cost per label can be higher than screen printing for massive orders, the lack of setup fees makes it the clear winner for smaller quantities.

The UK’s custom printing market is booming, with a projected annual growth rate of 11.5% between 2025 and 2030. Screen printing still holds the largest slice of the pie at over 54% revenue share, thanks to its efficiency for big runs of t-shirts and hoodies. But digital printing is catching up fast, driven by our growing love for personalised and unique clothing that often requires smaller, more detailed print jobs.

To help you decide, let’s put these two methods side-by-side. This table breaks down the key differences between screen and digital printing, so you can see at a glance which one aligns best with your project’s needs.

| Feature | Screen Printing | Digital Printing |

|---|---|---|

| Best For | High-volume orders (100+ units) with simple designs. | Small to medium batches, complex or full-colour designs. |

| Colour Limit | Limited; each colour adds cost and complexity. | Virtually unlimited; perfect for photos and gradients. |

| Setup Cost | High, from screen creation. | Very low to none. |

| Cost Per Item | Decreases significantly with higher volume. | Stays relatively consistent regardless of volume. |

| Turnaround | Slower, because of the screen preparation process. | Fast, ideal for quick production needs. |

| Feel | A thick layer of ink that sits on top of the fabric. | A softer feel as ink is absorbed into the fabric. |

Whether you choose the high-volume efficiency of screen printing or the creative freedom of digital printing depends on your specific goals.

Choosing between them usually boils down to three things: the complexity of your design, the size of your order, and your budget. For anyone thinking about bringing this process in-house, getting to grips with the equipment is critical. Our overview of the label printing machine for clothes offers a deeper look at the available textile labelling solutions. This knowledge allows you to have smarter conversations with manufacturers or make a sound investment in your own technology, making sure your production is perfectly aligned with your brand’s needs.

While traditional methods have their place, a much newer technology is making serious waves in apparel customisation and label printing for clothing. It’s called Direct to Garment, or DTG, printing. Think of it like the inkjet printer sitting on your desk at home, but instead of printing on paper, it applies specialised, water-based inks directly onto the fabric itself.

This process allows for astonishingly detailed, full-colour designs without the hassle of creating screens or going through complex setup procedures. For clothing brands, this unlocks a whole new level of creativity, especially when you want to print intricate graphics or photorealistic images directly onto your garments.

One of the cleverest uses of DTG technology for branding is the creation of tagless labels. Instead of dealing with a sewn-in or heat-transfer label that can often be scratchy and annoying, the brand logo, size, and care instructions are printed straight onto the inside of the garment.

This simple change puts the wearer’s comfort first. When a customer gets irritated by a traditional label, what do they do? They often cut it out, and your branding goes right along with it. A tagless label, however, is a permanent and completely unobtrusive part of the garment, making sure your brand stays put for its entire lifespan.

A tagless label integrates branding smoothly into the clothing itself. It sends a message of thoughtfulness and user comfort, reinforcing a brand’s commitment to a high-quality customer experience from the inside out.

It is no surprise that tagless labels have become the go-to choice for items worn close to the skin, like t-shirts, athletic wear, and children’s clothes. They get rid of the physical tag-a common source of irritation-and give the product a clean, premium feel.

DTG printing brings a host of advantages to the table, perfectly matching the fast-paced needs of today’s fashion businesses, particularly those selling online.

This kind of flexibility has made DTG a cornerstone of the e-commerce fashion boom. It enables small businesses and independent designers across the UK to compete with bigger players by offering unique, customised apparel without needing a massive upfront investment.

The market statistics tell the same story. Projections show that the UK’s Direct to Garment printing sector is on a steep growth trajectory, expected to hit an estimated revenue of USD 274 million by 2030. Growing from USD 130.8 million in 2024, this represents a compound annual growth rate of 13.6%. It clearly points to a major industry shift towards on-demand and personalised apparel production. You can find more on the drivers of this trend in this detailed UK DTG market outlook.

Choosing the right material for your clothing label is every bit as important as the design printed on it. The substrate-the actual fabric of the label-has a massive impact on the garment’s feel, its durability, and even your overall production cost. At the same time, you’ve got to get the legal side of things right. Navigating the rules for what must appear on that label is non-negotiable for any clothing brand in the UK.

This double act of material choice and legal compliance is at the heart of professional label printing for clothing. A beautiful label on the wrong fabric can cheapen your product, while a non-compliant one can land your business in hot water. Getting both right is the key to creating apparel that’s not just appealing, but also ready for the market.

Think of your label material as an extension of your garment. It needs to match the item’s purpose and reflect your brand’s commitment to quality. Each option brings its own unique blend of texture, toughness, and price.

Here are a few of the most popular choices:

The trick is to find the sweet spot between aesthetics and practicality. To learn more, our comprehensive guide on the best materials for labels has all the details you need to make a confident choice.

Let’s be clear: compliance isn’t optional. In the UK, the law dictates that specific information must be provided to the consumer on clothing labels. Get this wrong, and you could face having your products pulled from sale or other penalties, especially when you’re supplying major retailers.

At its core, labelling law is all about transparency. Customers have a right to know what they’re buying and how to look after it. Your label is the primary tool for delivering this information correctly and building that trust.

Here are the key UK requirements you absolutely must get right:

It’s interesting to see how this fits into the bigger picture. While the wider UK printing industry has seen revenues fall in traditional media-UK regional newspapers, for instance, saw a 16% drop in circulation in 2024-specialist areas like custom apparel branding are thriving. As old-school print declines, the strategic value of high-quality, compliant label printing for clothing has never been higher for making a brand stand out.

Choosing how to produce your clothing labels is a big decision. You can either partner with a specialised printing company or handle it all yourself, in-house. This choice will have a real impact on everything from your product quality and production speed to your overall costs.

There’s no single right answer here. Both paths have their pros and cons, and the best route for you really comes down to your business model, how many garments you’re making, and where you see your brand heading in the long run. This is the final step that turns your label printing for clothing ideas into tangible, physical products. It’s all about finding a reliable solution that just fits.

For most brands, especially if you’re just starting out or don’t have a background in manufacturing, outsourcing your label printing is the most sensible option. A good printing partner brings a wealth of experience and access to professional-grade equipment that you simply wouldn’t have otherwise.

When you’re vetting potential suppliers, here are the crucial things to look at:

Before you even think about signing a contract, have a list of questions ready. Ask about their specific experience with the material you want to use, what their proofing process looks like, and if there are any hidden fees. Doing this homework upfront helps you properly assess if they’re the right fit.

Building a strong, collaborative relationship with your label manufacturer is fundamental. For a closer look into this, checking out some proven strategies for working with labelling suppliers can give you a great framework for building a successful partnership.

For brands that crave maximum flexibility and need to produce smaller batches on the fly, taking control of label printing can be a brilliant move. This approach cuts out the lead times you’d face with an external supplier and lets you make changes or print one-offs whenever you need to.

Before you start shopping for equipment, here’s what you need to think about:

Bringing label printing for clothing in-house gives you complete authority over one of your garment’s most crucial finishing touches. It’s a powerful choice for flexible brands that have the resources and desire to manage the process directly, giving you unparalleled control over how your product is presented to the world.

When you’re getting into the specifics of producing apparel, questions about labels are bound to pop up. Here are some quick, straightforward answers to the queries we hear most often.

Hands down, that would be woven labels, particularly high-density damask ones. Because the design is literally woven into the fabric-not just printed on the surface-they can go through wash after wash without fading or falling apart.

This makes them the go-to choice for hard-wearing items like denim, outerwear, and any premium garment that’s built to last. They simply hold up better over the long haul.

Honestly, it varies quite a bit. There isn’t a single price tag, as the final cost depends on a few key things: the type of label you choose, the material, how many colours are in your design, and, of course, your order size.

Generally, woven labels cost more per piece than printed ones. The good news is that the price per label almost always drops as your order quantity goes up. A simple printed satin label might only be a few pence each on a large run, whereas a complex, multi-colour woven label will naturally cost more. The best way to know for sure is to get a few quotes based on your exact needs.

A Quick Tip on Budgeting: Don’t just look at the cost per label. Remember to account for any one-time setup fees for your design and the shipping costs from your supplier. That’s how you’ll get the true total cost.

For any clothing sold in the UK, the label absolutely must state the fibre content. You’ll need to list what it’s made of, like “100% Cotton” or a percentage breakdown for blends.

While not always a strict legal requirement for every single product, it’s standard practice-and often demanded by retailers-to also include:

Brand names and sizing are standard additions you’ll want to include for your customers, but they aren’t part of the legal compliance rules.

Yes, you certainly can, and it’s a great option if you’re just starting out or working on very small batches. The most common DIY method uses printable fabric sheets (either iron-on or sew-in) that you can run through a normal inkjet printer.

This gives you a ton of flexibility to experiment without a big investment. You’ll find the quality, feel, and durability won’t be on the same level as professionally made labels. For a more polished look and for larger production runs, outsourcing to a specialist printing company is the way to go as your brand grows.

When you’re ready to bring your label production in-house, Sessions UK has a full range of dependable labelling machinery. Whether you need a simple manual system for a startup or a high-speed automatic solution for a full-scale clothing line, we provide the expert advice and support to find your perfect match.

Take a look at our professional labelling solutions to see how we can help.

Copyright © 2026 Sessions Label Solutions Ltd.