Material clothing labels might be small, but they carry a lot of weight. They’re the silent storytellers of a garment, detailing everything from its fibre content and country of origin to the best way to care for it. This little tag is much more than just a brand name; it’s a critical element that builds trust with your customers and speaks volumes about your quality standards long after the item has left the shop.

Think of a material clothing label as a garment’s passport. It holds all the information that guides the consumer, protects your brand, and keeps you on the right side of the law. For shoppers, these labels answer the big questions: What am I really buying, and how do I look after it? For brands, they’re a must-have for product presentation and legal compliance.

The role of these labels has changed quite a bit over the years. Here in the UK, their story really begins with the Merchandise Marks Act of 1887. This law made it mandatory for manufacturers to specify a product’s material and origin, initially to prevent foreign goods from being passed off as British-made. This early piece of legislation set the stage for consumer protection and fair trade, shaping labelling rules across the globe. You can find out more about the history of clothing labels and their evolution to see just how far they’ve come.

Today, their purpose is even clearer, covering several key functions:

A clothing label closes the loop between the maker and the wearer. It’s a pocket-sized source of truth that influences buying decisions, helps the product last, and helps build a solid brand reputation. Every single detail, from the material it’s made from to the text printed on it, adds to the overall experience.

Picking the right material for your clothing labels is one of those small decisions that makes a huge difference. It’s a detail that quietly tells your customers a story about your brand’s quality, comfort, and character, often before they’ve even tried the garment on. The feel of that label against their skin, how sharp your logo looks, and whether it survives the wash-it all starts here.

Think about it: a scratchy, stiff tag on a soft babygrow just feels wrong. It sends a mixed message. That’s why getting the material right is critical for creating a consistent brand experience that resonates with your customers.

Different label materials bring their own unique strengths to the table. The best fit for your brand will come down to a mix of your overall aesthetic, the type of clothing you make, and your budget. Let’s break down some of the most popular choices.

This table provides a quick comparison of the most common materials, helping you see at a glance which one might suit your needs.

| Material | Feel & Texture | Durability | Best For | Perceived Value |

|---|---|---|---|---|

| Cotton | Soft, natural, slightly rustic | Good, but can fade or fray over time | Organic products, children’s wear, casual apparel | Earthy, comfortable, approachable |

| Satin | Smooth, silky, gentle on the skin | Good, especially for printed designs | Lingerie, high-end t-shirts, items worn close to the skin | Elegant, comfortable, accessible luxury |

| Damask Woven | Smooth, with a dense, high-end feel | Excellent, withstands many washes | Luxury apparel, designer pieces, outerwear | Premium, sophisticated, high quality |

| Taffeta Woven | Stiffer, slightly crisp texture | Very durable, holds its shape well | Outer branding, care labels, budget-conscious projects | Functional, sturdy, economical |

As you can see, each material projects a different feel. A soft cotton label instantly suggests natural comfort, while a finely woven damask label speaks to superior quality and meticulous detail. It’s all about matching the material to the message you want to send.

Beyond the look and feel, a few practical points will guide your decision. How a label performs over time is a big deal for customer satisfaction.

A key factor is durability against washing. Woven labels, especially high-density damask, tend to hold up much better through countless laundry cycles compared to some printed options, which can fade.

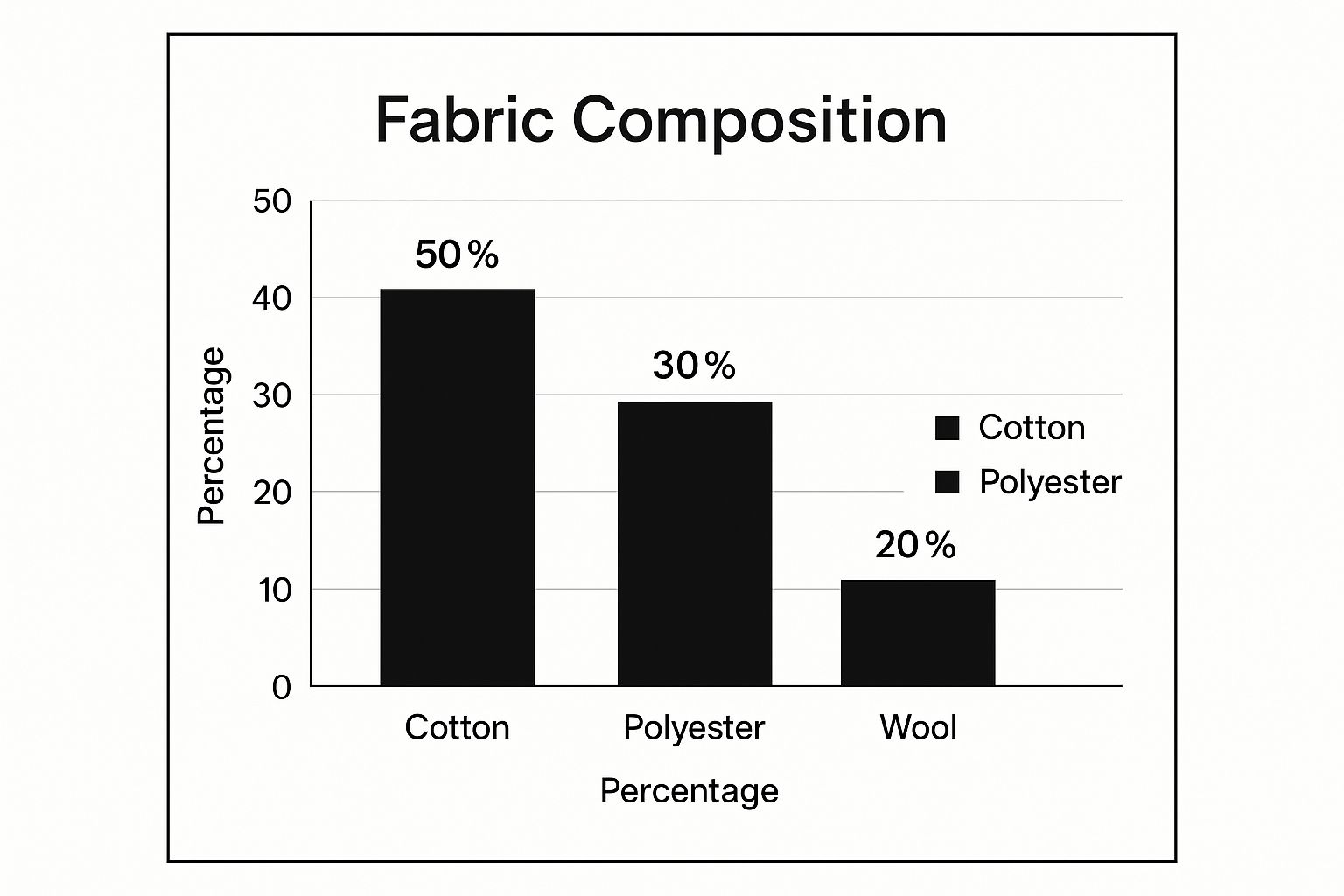

The data here shows that cotton and polyester blends are everywhere in the textile world. This makes it even more important to pick labels that work well with these common fabrics. For brands juggling different materials, understanding the ins and outs of label printing for clothing is a helpful step toward a professional, cohesive look.

Finally, don’t forget comfort. For anything worn close to the body, like t-shirts or underwear, a softer material like satin or cotton is almost always the better choice over something stiffer like taffeta. It’s a small touch that shows you’ve thought about the entire wearing experience.

How a label is constructed and attached to a piece of clothing is every bit as important as the material it’s made from. These choices shape the final look, feel, and toughness of the label, which in turn says a lot about your brand’s commitment to quality. When it comes down to it, you’re looking at two main paths: printed or woven labels. Each has its own place and purpose.

Printed labels are pretty much what they sound like. Ink is transferred directly onto a base material, typically something soft like satin or cotton. This method is brilliant for complex, colourful designs with tiny details, and it’s usually kinder on the budget. That’s why you’ll often find them on t-shirts or kids’ clothing, where comfort against the skin and detailed graphics are key.

Woven labels are a different beast entirely. Here, threads are meticulously woven together to create both the label and the design within it. This process gives you a classic, premium finish that feels substantial and is built to last. For high-end fashion, heavy-duty outerwear, and any garment where you want the label to signal luxury and endure for years, woven is the way to go.

| Feature | Printed Labels | Woven Labels |

|---|---|---|

| Best For | Intricate graphics, fine text, soft feel | Brand logos, classic look, high durability |

| Common Use | T-shirts, lingerie, care instructions | Outerwear, designer apparel, premium branding |

| Cost | More economical, especially for multi-colour designs | Higher initial cost, but excellent longevity |

| Durability | Good, but ink may fade over many washes | Excellent, as the design is part of the fabric |

Choosing between printed and woven is a balancing act. You have to weigh your budget against your design’s complexity and the feeling of quality you want to convey.

Once you’ve picked your label type, the next decision is how to fold and attach it. This isn’t just a minor detail; it dictates the label’s role and how it sits on the finished garment. Different folds work best in different places, whether that’s the collar, the hem, or tucked away in a side seam.

A label’s fold isn’t just a finishing touch; it’s a deliberate design choice that impacts wearer comfort and brand presentation. The right fold helps the label sit flat, remain secure, and interact with the garment as intended.

Some of the most common folding styles for material clothing labels you’ll see are:

Getting the combination of construction and fold right is critical. Think about it: a high-quality woven label with a classic end fold at the neckline instantly creates a premium feel. A simple, printed, centre-folded care label delivers information discreetly without getting in the way. This kind of thoughtful approach helps your labels perfectly match your garment’s design, your budget, and your quality aspirations.

Navigating the legal side of clothing labels is something every apparel brand in the UK has to get right. If you don’t, you could be facing serious headaches like product recalls or fines, which is a situation no one wants to be in. At their core, these rules are here to protect consumers, making sure they know exactly what they’re buying.

The foundation of UK regulation is all about honesty and accuracy. Your material clothing labels must give people clear, correct information so they can make smart choices. This isn’t just a nice-to-have; it’s a legal must that builds consumer trust and product accountability across England, Scotland, and Wales.

What absolutely has to be on the label? The single most important legal requirement is disclosing the fibre content. This is the cornerstone of UK textile labelling.

These rules are all about giving consumers the full picture. The official UK government guidance on textile labelling puts the responsibility for getting this right squarely on the shoulders of manufacturers and retailers. For the nitty-gritty details, you can always check out the UK government guidance on textile labelling.

What about more complicated items, like a jacket with a different lining? The regulations cover this clearly: you have to label the composition of each distinct part separately.

For a garment with a main body of 100% wool and a lining of 100% polyester, the label must list both components and their respective fibre contents. This prevents any confusion and helps the customer understand the entire product’s makeup.

Getting this level of detail right is absolutely critical for staying compliant and earning customer trust.

While fibre content is the main legal requirement, other details have become industry standards that customers fully expect to see. Leaving them off can hurt how people see your brand.

Keeping up with these regulations is a continuous process. For a closer look at how these rules are changing, our guide on understanding label regulations provides a 2025 outlook for production teams. By treating the legal minimums as your starting point and then adding useful, customer-first information, you can create labels that aren’t just compliant-they’re a genuine asset to your brand.

The world of material clothing labels is undergoing a massive transformation. For years, labels were a simple afterthought, but now they’re at the forefront of a movement driven by two powerful forces: consumer demand for transparency and a serious commitment to environmental responsibility. Brands are now looking far beyond just the feel or cost of a label. They’re thinking about the entire lifecycle of their products, and the label is becoming a key way to communicate their values.

This means we’re seeing a major pivot towards sustainable and digital solutions. Eco-friendly materials, for instance, are quickly becoming the new normal. Instead of relying on virgin polyester, savvy brands are choosing organic cotton, recycled polyester (rPET), or even different options like bamboo and cork. It’s a smart move that not only shrinks their environmental footprint but also proves to customers they’re genuine about their green claims.

This isn’t just a passing trend; it’s being cemented by new legislation. Across the UK and Europe, stricter regulations are forcing brands to be much more upfront about their environmental impact. New eco-label rules now require larger companies to disclose details, from a product’s reparability and recyclability to the presence of microplastics.

This regulatory push directly answers the growing chorus of consumers demanding honesty. People want the full story: where did their clothes come from? How were they made? And what should they do with them when they’re finished with them? A well-designed, sustainable label provides these answers right on the garment. You can learn more about the best practices for labelling and sustainability heading towards 2025.

This new regulatory scene is about more than just listing fibres. It demands a complete, honest picture of a product’s journey, pushing for clear, verifiable claims about its real-world environmental performance.

The next frontier is where the physical label meets the digital world. Digital Product Passports (DPPs) are about to become a major development, linking a garment to a vast repository of online information. All it takes is a quick scan of a QR code on the label to unlock an item’s entire history.

This is a phenomenal opportunity for brands to connect with their customers on a much deeper level. Imagine what a DPP could show you:

This digital layer turns a humble clothing label into an interactive gateway. It gives people the knowledge they crave to make better choices and, in doing so, builds a foundation of trust with the brand. This blend of sustainable materials and digital innovation isn’t just a possibility-it’s the future of clothing labels.

When you’re bringing a garment to life, a lot of practical questions pop up, especially around material clothing labels. For new brands, in particular, getting straightforward answers is key to getting the design right and staying compliant. Let’s walk through some of the most common queries we hear.

At its core, the one absolute legal must-have on a UK clothing label is the fibre content. You need to clearly list the material composition, with each fibre presented in descending order by its percentage. A typical example would be something like “70% Cotton, 30% Recycled Polyester“.

While things like care instructions and the country of origin aren’t strictly required by law for every single product, they are absolutely considered best practice. Today’s shoppers have come to expect this information. And remember, if you’re selling online, these details must be visible to the customer before they hit the buy button.

Keep in mind that some items, like those containing fur or other animal-derived materials, have extra rules. When in doubt, it’s always better to be fully transparent. It’s how you build trust.

The choice between a woven or a printed label really boils down to your brand’s personality, the type of garment you’re making, and your budget. Each one has its own strengths.

A good rule of thumb? Use woven labels for a lasting brand statement on higher-value items and go with printed labels for comfort and detailed graphics on everyday wear.

Choosing sustainable materials like organic cotton or recycled polyester for your labels does more than just tick a box. It sends a powerful message about your brand’s commitment to the environment, which is a massive deciding factor for a growing number of shoppers. It can be a genuine point of difference in a very crowded market.

Making this switch also helps reduce your brand’s overall environmental footprint. As consumers and regulators alike push for greater transparency, adopting sustainable practices now positions your business for the future. It’s a great way to build a loyal community of customers who share your values. If you’re running into challenges, you can find answers to frequently asked questions about common labelling issues and how to solve them.

Yes, absolutely! In fact, it’s very common and often the most practical way to go. Using a few different labels on one piece of clothing lets you organise information clearly without sacrificing comfort.

A typical setup might look like this: a main brand label at the neckline, a separate care and content label tucked away on an inner side seam, and maybe a small size tag on another seam. This approach keeps the primary branding clean and visible while the detailed regulatory info is kept out of the way. It also lets you mix and match, maybe using a premium woven brand label with a simple printed care label to get the best of both worlds, balancing aesthetics with your budget.

Copyright © 2025 Sessions Label Solutions Ltd.