Finding the right labelling machines for your production line is essential for efficiency, accuracy, and brand consistency. At Sessions UK, we supply a comprehensive range of labelling equipment, from simple desktop units to fully integrated, high-speed systems. Whether you need an automatic solution for a fast-moving packaging line or a specialised machine for pharmaceutical products, we have the expertise to provide the right equipment for the job. Our solutions ensure your products are labelled correctly every time, meeting both regulatory standards and consumer expectations. Browse our machine categories below or view our full range of labelling systems to find the perfect solution for your business.

Wrap Round

Throughput: 20 products per minute

Product Diameter Range: 13 -120mm

Operation: Semi Automatic/ product arm

Flat bottles or cartons

Output - up to 20 per minute

Range - Up to 250mm size products

Operation - Semi auto

Flat products - Label on top or side

Output - up to 100 labels per minute

Range - 20 to 230mm wide labels

Operation - Automatic

Flat bottles or cartons

Output - 20 per minute

Range - 20 to 250mm

Operation - Semi auto / product switch

Flat products

Output - up to 60 per minute

Range - 20 to 160mm wide label

Operation - Automatic

Compact desktop tube labelling system

Print and wrap round

Range - 10 to 20mm diameter

Operation - Semi auto / product switch

Print and wrap round

Output - up to 20 per minute

Range - 20 to 100mm diameter

Operation - Semi auto / product switch

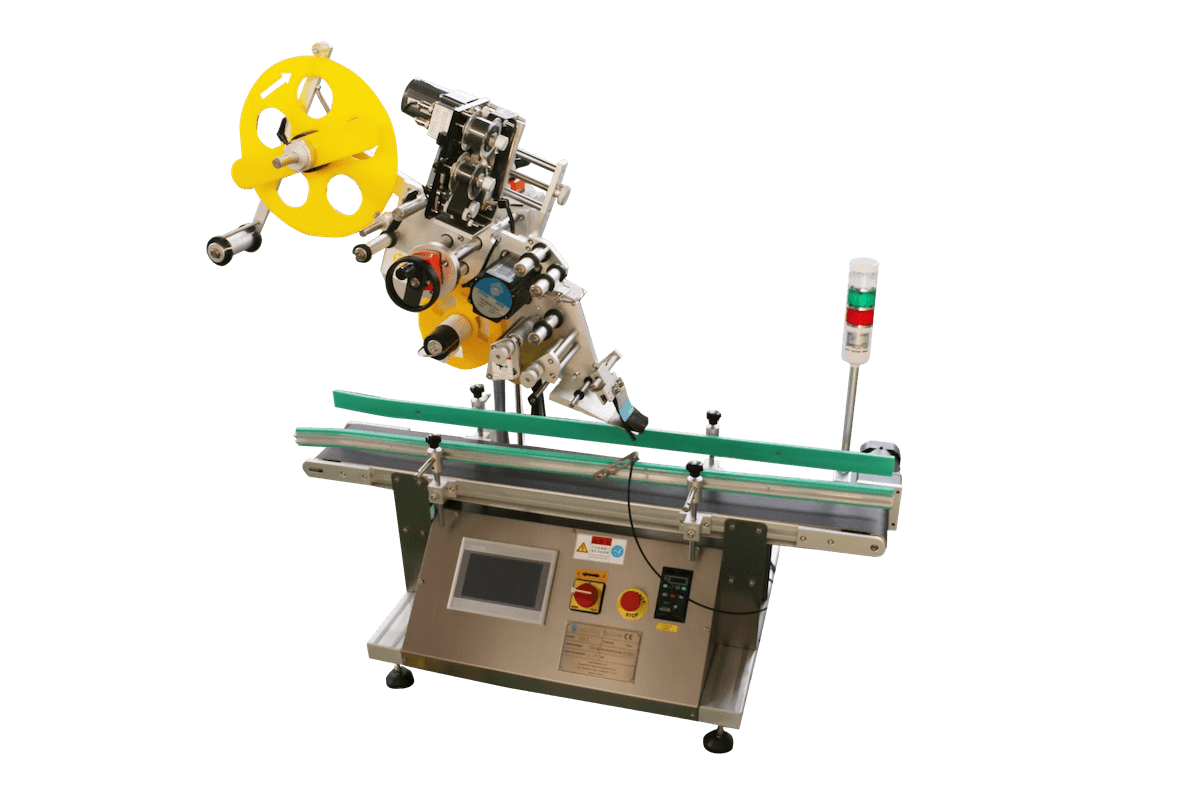

Flat Products

Output - up to 50 per minute

Range - 20 to 80mm wide

Operation - Semi auto / belt conveyor

Flat products

Output - up to 100 labels per minute

Range - 20 to 160mm wide label

Operation - Automatic

Flat products

Output - up to 100 labels per minute

Range - 20 to 190mm wide labels

Operation - Automatic

Flat products - High precision

Output - up to 15 per minute

Range - 5 to 100mm wide

Operation - Semi auto / product switch

Front & Back

Output - up to 100 per minute

Range - 20 to 195mm high labels

Operation - Automatic / Slat Conveyor

Wrap round

Output - up to 150 per minute

Range - 20 to 100mm wide products

Operation - Automatic / slat conveyor

Wrap round small

Output - up to 100 per minute

Range - 15 to 50mm diameter

Operation - Automatic / roller conveyor

Wrap round conical

Output - up to 25 per minute

Range - up to 5 litre buckets

Operation - Automatic / slat conveyor

Wrap round

Output - up to 100 per minute

Range - 20 to 100mm diameter

Operation - Automatic / slat conveyor

Wrap round

Output - up to 10 per minute

Range - 20 to 100mm diameter

Operation - Manual / handle

Round products

Output - up to 50 per minute

Range - 25 to 80mm diameter

Labels up to 150mm in height

Operation - Semi auto / belt conveyor

Wrap round

Output - up to 25 per minute

Range - 12 to 250mm diameter

Operation - Semi auto / footswitch

Widths - 6, 10 and 16"

Setup Guide Included

Pharmaceutical tray labeller

Output - up to 10 per minute

Range - Label on long or short edge

Operation - Semi auto / product switch

Wrap round

Output - up to 60 per minute

Range - 10 to 35mm diameter

Operation - Automatic / step conveyor

Option - In-register labelling

Flat products

Output - up to 30 per minute

Range - 20 to 100mm label size

Operation - Semi auto / footswitch

A labelling machine is more than just a piece of equipment. It is a critical component of your production and packaging process. The right machine improves operational efficiency, reduces manual labour costs, and eliminates the errors associated with hand labelling. In today’s competitive market, professional and accurate labelling is non-negotiable.

Key Benefits Include:

Investing in a suitable labelling system is an investment in your brand’s quality, efficiency, and compliance.

The term ‘labelling machine’ covers a wide range of equipment. The best choice depends on your production volume, product type, and budget. We provide solutions across the entire spectrum, ensuring a perfect fit for every operational need.

For businesses with high production volumes, automatic labelling machines offer a complete, hands-free solution. These systems are integrated directly into your production line. Products are fed via a conveyor, automatically sensed, and labelled with high precision without any operator intervention. They are the standard for large-scale manufacturing, food processing, and bottling plants. We also provide industrial automatic labelling machines built with robust materials like stainless steel for demanding, 24/7 environments.

Semi-automatic machines offer a middle ground between manual labelling and full automation. They are ideal for small to medium-sized businesses, batch production, or for companies with a diverse range of products. With these machines, an operator typically places the product into a jig, and the machine applies the label when activated by a footswitch or button. They provide excellent accuracy and a significant speed increase over hand labelling without the investment required for a fully automatic line.

When throughput is the primary concern, high speed labelling machines are the answer. Engineered for maximum output, these machines use advanced servo-driven motors and sophisticated control systems to apply labels at incredible speeds, often exceeding 500 products per minute. They are essential for industries like beverage bottling, canned goods, and fast-moving consumer goods where production lines run continuously. These systems are designed for reliability and precision, even at top speed.

A print and apply labelling machine combines a thermal transfer printer with a label applicator. This allows you to print variable data – such as barcodes, batch numbers, dates, and shipping information – onto a blank label and immediately apply it to a product, case, or pallet. They are indispensable in logistics, warehousing, and food production where traceability and real-time data are critical. This type of sticker labelling machine removes the need for pre-printed label stock, reducing waste and increasing flexibility.

The vast majority of modern labellers are self adhesive labelling machines. They are designed to work with pressure-sensitive labels supplied on a roll. The machine peels the label from its backing paper and applies it to the product with pressure. This technology is incredibly versatile and can be used for almost any product shape or material, from glass bottles to plastic tubs and cardboard boxes.

Different industries have unique labelling requirements. We offer specialised machines designed to handle the specific challenges of your sector. Our “explore by application” tool can help you narrow down the best options for your products.

Labelling bottles, jars, and other cylindrical containers is one of the most common applications. Our range of bottle labelling machines can handle this with ease. For simple applications, a wrap around labelling machine applies a single label around the circumference of the bottle. For products requiring brand and ingredient information on separate labels, a front and back labelling machine is the ideal solution, applying both labels simultaneously with perfect alignment. We supply machines for wine, beer, spirits, sauces, and jars.

The food industry demands hygiene, reliability, and accuracy. Our labelling machines for food are designed to meet these standards. Built with food-grade materials like stainless steel, they are often designed for easy wash-downs. Whether you need to label cans, boxes, trays, or pouches, we have a solution. We also provide dedicated labelling machines for food products that can handle the specific shapes and textures of items like cheese, meat packs, and ready meals.

Accuracy and validation are paramount in the pharmaceutical sector. Our pharmaceutical labelling machines are engineered for the highest levels of precision and compliance. These systems often include features like vision systems for barcode verification, pharmacode reading, and rejection mechanisms for faulty labels. They are used for labelling vials, ampoules, syringes, and cartons, ensuring every product meets strict regulatory standards.

In the cosmetics industry, label presentation is a key part of the brand. Minor imperfections like creases or bubbles are unacceptable. Our cosmetic labelling machines are designed to apply labels flawlessly to jars, tubs, tubes, and unusually shaped containers. They deliver the high-end finish required for premium products, ensuring your packaging looks perfect on the shelf.

A complete labelling solution is more than just one machine; it’s an integrated system. Understanding the components helps you choose the right setup.

At the heart of every machine is the label applicator. This is the head that dispenses the self-adhesive label from its backing roll and applies it to the product. The sophistication of the label applicator often determines the speed and accuracy of the entire machine. Simpler applicators are used in semi-automatic machines, while advanced, servo-driven models are found in high-speed and print-and-apply systems.

For any automatic labelling machine to work effectively, product handling must be smooth and consistent. The conveyor system transports the product to the labelling station. Additional components like spacing wheels, scroll feeds, or orientation belts are used to ensure each item is perfectly positioned for label application. The quality of product handling is just as important as the quality of the applicator itself.

Our packaging and labelling machines are designed to integrate seamlessly into a wider production line. They can be synchronised with other equipment such as fillers, cappers, cartoners, and case sealers. This creates a fully automated process from start to finish, maximising efficiency and minimising the need for manual intervention.

For factories and production facilities that operate around the clock, standard equipment may not be sufficient. We supply robust industrial labelling systems built for durability and continuous performance. These industrial labelling machines are constructed from heavy-duty components and are designed to withstand harsh conditions, including dust, moisture, and temperature fluctuations. An industrial automatic labelling machine is the cornerstone of any large-scale manufacturing operation, providing reliability you can count on.

Selecting a partner for your labelling needs is a critical decision. As one of the UK’s leading labelling machines suppliers, Sessions UK offers more than just equipment. We provide a complete service from initial consultation to installation, training, and ongoing support.

When choosing a supplier, consider the following:

Automatic labelling machines are fully integrated into a production line and require no operator to feed products. Semi-automatic machines require an operator to place each product before the label is applied. Automatics are for high volume, while semi-automatics suit smaller batches.

Speed varies greatly depending on the model and application. Semi-automatic machines can label 10-20 products per minute. Standard automatic machines typically run at 60-120 products per minute, while specialised high speed labelling machines can exceed 500 per minute.

Yes. Most of our machines are adjustable and can be configured to handle a range of product and label sizes. We can provide change parts for machines that need to run multiple, significantly different products.

To give you an accurate quote, we need to know your product (shape, dimensions), your label (size, position), and your required production speed (products per minute or hour). Samples of your products and labels are always helpful.

Yes. We offer a full installation and commissioning service for our automatic systems. Our engineers will set up the machine, integrate it with your line, and provide comprehensive training for your operators to ensure they can run and maintain the equipment effectively.

Choosing the right labelling machine is a vital step in optimising your production process. With our extensive range and expert knowledge, Sessions UK is perfectly positioned to help you find the most effective and reliable solution for your business.

Browse our categories or use our “explore by application” feature to identify the best machine for your needs.

For a detailed consultation, contact our expert team today. We will assess your requirements and recommend a labelling system that delivers performance, quality, and value.

Copyright © 2026 Sessions Label Solutions Ltd.