Think about giving every item of clothing its own unique digital voice-a voice that can be heard from across a room without ever needing to be seen. That is what RFID tags for clothing do. They are small, smart labels that hold data and use radio waves to communicate with a reader. This simple but powerful idea allows retailers to track their stock with incredible speed and accuracy, leaving traditional barcodes behind.

At its heart, Radio Frequency Identification (RFID) is a type of wireless communication. Picture a silent conversation happening constantly across a busy shop floor. Instead of needing to point a scanner directly at a barcode, an RFID system uses radio waves to automatically identify, track, and manage every tagged item.

The whole system comes down to three key components working together. Each piece plays a specific part in turning a simple garment into a source of live, useful information.

First, you have the RFID tag itself. This is much more than a sticky label. It is a tiny device with a microchip that holds a one-of-a-kind identification number and a small antenna to send that information out. These tags are usually built right into a garment’s price ticket, hang-tag, or even sewn into a woven care label.

Next is the RFID reader. This device is the one asking the questions. It sends out radio waves that “wake up” any tags nearby. Once a tag gets this signal, it instantly sends its unique ID number back to the reader. These readers can be handheld devices for staff doing stock counts on the move, or they can be fixed in place at key spots like stockroom doors or checkouts.

Finally, there is the software system. This is the brain of the entire operation. It gathers all the data streaming in from the readers, processes the information, updates your inventory records in real-time, and displays it all in a way that staff and managers can actually use.

The real magic of RFID is its ability to read hundreds of tags at once, without needing a direct line of sight. An employee can scan an entire rack of shirts in just a few seconds-a job that would have taken ages with an old-school barcode scanner.

This capability is a massive jump from older methods. Barcodes demand a one-by-one scan, which is slow, painstaking, and full of opportunities for human error. RFID technology for clothing makes these manual checks a thing of the past, giving you a constantly accurate picture of what you have in stock and where it is.

To truly grasp the difference RFID makes, it helps to see it side-by-side with the technology it is replacing. Here is a quick comparison of how RFID stacks up against traditional barcodes for managing clothing.

| Feature | Barcode Technology | RFID Technology |

|---|---|---|

| Line of Sight | Required for every scan | Not required; can read through materials |

| Scan Speed | One item at a time | Hundreds of items per second |

| Data Capacity | Stores limited product data | Stores unique ID for each item |

| Durability | Easily damaged or obscured | Can be embedded and protected |

| Automation | Manual process, labour-intensive | Enables automated tracking and counting |

As you can see, it is not just a minor upgrade. For apparel retailers wrestling with huge volumes of stock, the efficiency gains from moving to RFID are significant.

Anyone working in the UK’s fashion retail market knows it is a tough game. The competition is fierce, margins are wafer-thin, and every inefficiency hurts. Retailers are constantly up against rising operational costs, from staffing to shipping, which makes old-school stock management a serious liability.

Think about it: manual stock counts and barcode scanning are painfully slow and full of opportunities for human error. A single tired employee missing a box or mistyping a number can throw your entire inventory count off. These small mistakes snowball, leading to poor reordering choices, cash getting locked up in unpopular items, and, worst of all, lost sales.

In today’s fast-paced world, customers expect to get what they want, when they want it. If they see an item online and find it is not actually in the shop, that is more than just a disappointment-it is a reason for them to go elsewhere. This is exactly where older methods fail, especially now that physical and digital shopfronts need to be perfectly in sync.

That gap between what your system says you have and what is actually on the shelf is a direct hit to your bottom line. It causes a cascade of problems:

These challenges are not just limited to fashion; many businesses are seeking better commercial retail industry solutions to boost their efficiency. This trend is backed by some serious growth figures. The UK’s RFID sector is projected to soar from USD 594.67 million to USD 1,415.42 million by 2032, which is a compound annual growth rate of 10.1%. This boom is all about retailers demanding better automation.

This is where RFID tags for clothing come in. They give UK retailers the real-time, accurate data they need to not just survive, but to thrive. By offering a near-perfect, live snapshot of every single item, the technology tackles those core problems head-on.

With RFID, a full stock-take that once took an entire team a whole day can now be done by one person in less than an hour. The difference in speed and accuracy is a complete shift for daily operations.

This instant visibility means smarter decisions. Retailers can manage stock across all their locations with confidence, fulfilling an online order from the nearest shop without the fear of letting a customer down. Fusing the right technology with a smart plan is key, something we explore further in our guide to labelling and marketing strategies for industrial success.

Having better control means fewer lost sales and a much stronger, more resilient business.

Picking the right RFID tags for clothing is not a one-size-fits-all decision. The tag you settle on will directly influence everything from the garment’s durability to your customer’s experience at the checkout. It also affects how smoothly you can apply the tags to your products in the first place.

For most retail environments, the go-to standard is the Ultra High Frequency (UHF) tag. It is popular for a good reason: its impressive read range means you can scan hundreds of items in a single pass without needing a direct line of sight.

The market for these tags is exploding. In 2023, the global UHF RFID clothing hang tag market was valued at a huge $5.24 billion. It is projected to rocket to $15.79 billion by 2032, according to this UHF RFID clothing hang tag market report. This phenomenal growth, both here in the UK and globally, signals a massive industry shift away from tedious manual stock counts and towards instant, item-level visibility.

Different clothing items and business needs will call for different kinds of tags. The three most common formats you’ll come across each have their own pros and cons, making them better suited for specific jobs within the fashion industry.

Think about the entire journey of your garment. A delicate silk blouse needs a very different tagging solution than a pair of rugged work trousers designed for years of hard use.

Your choice should be guided by a few practical questions about your products and your processes.

What’s the fabric? A delicate material might not stand up to the heat-sealing process. Will the tag be snipped off at purchase, or does it need to survive for the garment’s entire lifespan? Answering these simple questions is the key to matching the right tag to the right job.

Let’s move from theory to practical application, which is where the real value of RFID tags for clothing truly shines. Putting an RFID system in place is about tracking the entire journey of a garment, from the moment it is tagged at the factory right through to its final scan on the sales floor. This process turns every single item into a smart, trackable asset, giving you a complete, real-time picture of your stock.

The journey starts with what is known as ‘source tagging,’ where the RFID labels are attached during manufacturing. When these tagged garments arrive at a distribution centre or a store, they simply pass through fixed readers at the receiving docks. Inventory records are updated instantly without anyone ever needing to open a box or scan a barcode. It is a hands-off approach that all but eliminates the human error that plagues manual checks.

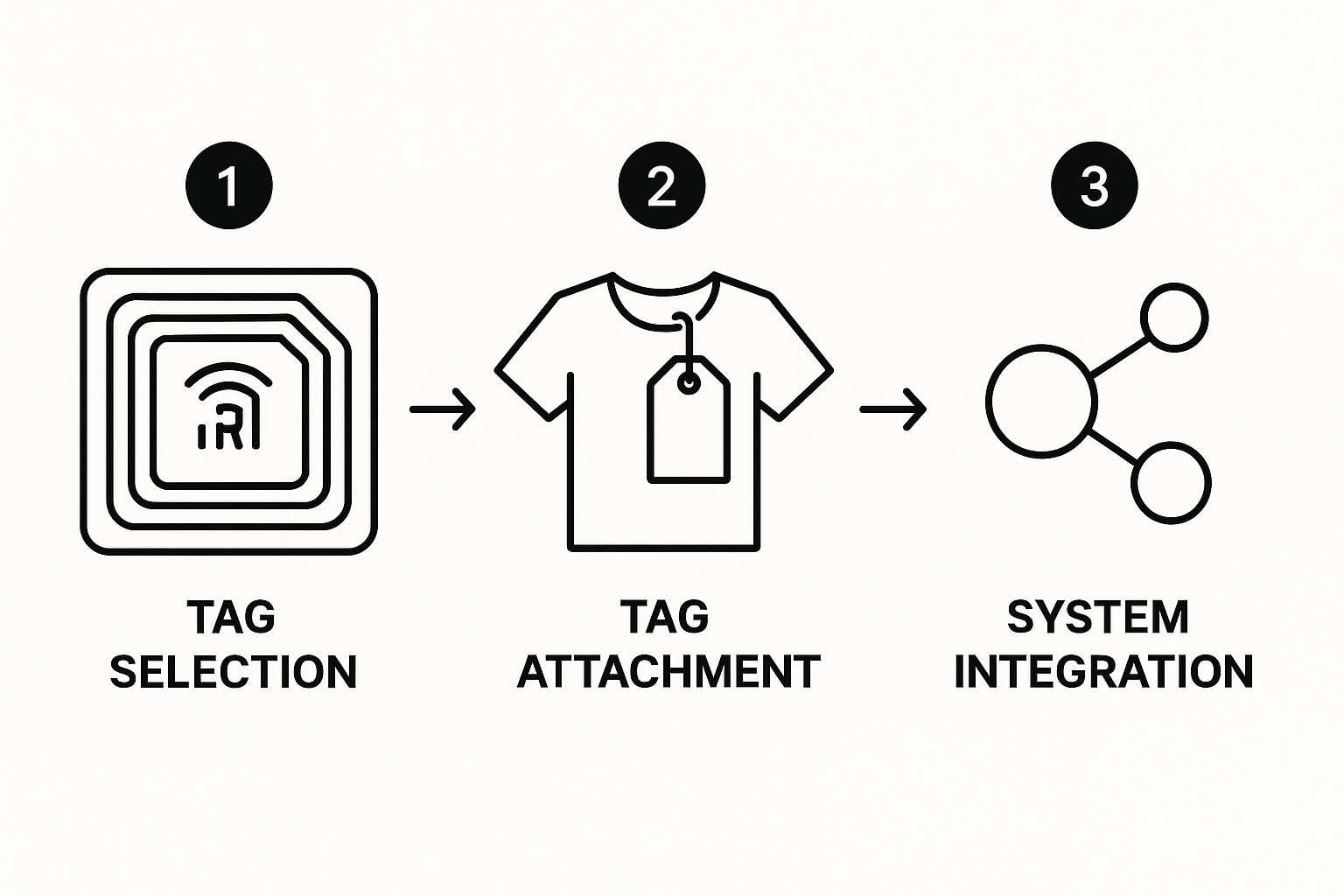

This image shows the core stages for bringing RFID technology into your clothing retail operations.

The flow is a logical progression. From choosing the right tag to integrating the data, each step builds on the last to create powerful operational intelligence.

Once the clothes are in the store, the technology really gets to work. Staff can use handheld readers to perform incredibly fast cycle counts, scanning entire racks or shelves in just a few seconds. A task that once took a full team and hours of tedious manual counting can now be done by one person before the shop even opens, and with far greater accuracy.

Think about it: a typical manual count might achieve 85-95% accuracy on a good day. RFID systems regularly push that figure to 99% or even higher.

This level of precision has a massive impact on day-to-day operations. Imagine a customer asking for a specific size or colour. Instead of a frantic search, your staff can check both the sales floor and stockroom availability in real-time from a single device. When items are moved from the back room to the front, fixed readers at the doorway can automatically log the transfer, keeping your inventory map constantly up to date.

The goal here is achieving near-perfect stock accuracy. This reliability means you can finally trust that the numbers in your system perfectly reflect what is physically available in your stores.

This newfound accuracy is the bedrock of a successful omnichannel strategy. When a customer browses your website, the stock levels they see are real and trustworthy. This prevents the frustration of “phantom stock”-items that your system says you have but are nowhere to be found-and allows services like “buy online, pick up in-store” to run without a hitch.

Achieving this requires a consistent approach across all your products. For any business considering this technology, reviewing established guidelines to get it right from the start is worthwhile. You can learn more about how to implement labelling standards to build a solid foundation for your system.

By following a clear process, retailers can dramatically cut the labour costs tied to manual counts and build a stock file they can truly rely on.

While RFID tags for clothing are brilliant for managing stock, they also pack a powerful punch as a modern security tool. It is a huge leap forward from the old Electronic Article Surveillance (EAS) systems that would just beep, telling you something had left the shop but not what. With RFID, you get item identification and security rolled into one smart tag.

This dual role is incredibly important, especially now. In the UK, retailers are grappling with a surge in theft and mounting operational pressures, making RFID less of a luxury and more of a necessity. During 2023/24, UK retailers were hit with over 55,000 theft incidents every single day, adding up to a mind-boggling £2.2 billion in losses. It is no wonder so many are turning to RFID to protect their assets.

The most familiar security setup uses Point-of-Exit (POE) antennas. These are the sleek readers you see at store entrances, which are constantly scanning for active RFID tags. When a customer buys a garment, the tag is simply deactivated at the till. But if an item with a live tag passes through those exit readers, an alarm goes off immediately.

It is a powerful deterrent. And unlike the old-school alarms, this is an intelligent alert linked to a specific product.

When an alarm sounds, staff know precisely which product triggered it. This gives them real-time, useful information for loss prevention, helping them spot which items are being targeted and uncovering theft patterns that would otherwise be invisible.

This ability to know exactly what was stolen, the moment it happens, is where RFID really shines. You are no longer waiting weeks for a stock-take to reveal vague discrepancies. Instead, you get instant feedback. This data helps you build a much clearer, more accurate picture of your security weak points.

With this detailed loss prevention data, retailers can:

RFID tags are primarily aimed at stopping external shoplifting. A solid loss prevention plan also needs to include strategies for preventing employee theft. The same principles of security and traceability are just as relevant for internal controls, a concept we explore in our article on security labels in the pharmaceutical industry. This makes RFID a formidable tool for protecting your bottom line from all angles.

As more fashion retailers look into RFID, the same practical questions tend to pop up. It makes sense. Before you begin, you need to understand the nuts and bolts of how these tags work day-to-day, from durability to cost and customer privacy. Let’s tackle some of the most frequent queries about using RFID tags for clothing.

Making the switch to RFID is not just about getting your stock counts right; it is about creating a smarter, more sustainable business. When you embed this technology directly into your garments, you open up new ways to reduce waste and give your products a longer, more useful life-something today’s shoppers really care about.

Absolutely, but it all comes down to choosing the right tool for the job. The durability of an RFID tag depends entirely on its design and what it was made for.

The golden rule is to always check the manufacturer’s specifications. This will tell you everything you need to know about the tag’s resistance to water, heat, and pressure, helping you pick the right one for each garment.

The cost of getting an RFID system up and running can vary quite a bit, but it is often more manageable than you might think, especially for a smaller, independent shop. It is best to see it as an investment that pays for itself.

Your main costs will fall into three buckets:

While there is an initial setup cost, many small businesses are surprised by how quickly they see a return. The time saved on manual stock-takes is enormous, you lose fewer sales to out-of-stocks, and theft prevention gets a serious boost.

Many suppliers now offer starter kits or flexible systems. This means you can begin with a basic setup and then add more components as your shop grows and your needs change.

This is a very important question, and one the retail industry has taken seriously. Reputable retailers and technology providers stick to strict guidelines designed to protect customer privacy.

Here is the key thing to remember: the RFID tag itself holds a unique serial number for the product, nothing more. It contains absolutely none of the customer’s personal information. To add another layer of protection, the tag is deactivated at the point of sale. Once the item has been paid for, the tag goes silent and can no longer be read by any RFID scanners.

Being open and honest is key. Simply letting customers know that the tags are only used for inventory management and security-and that they are switched off at the till-helps build trust and shows there is nothing to worry about.

RFID makes the whole shopping trip better in very real, tangible ways. It makes things faster, smoother, and far less frustrating for the customer.

For starters, it guarantees stock availability is spot-on. If your website says a specific dress is in stock at the shop, your customer can be confident it will actually be there. No more wasted trips or disappointment. In the shop, an assistant with a handheld reader can find a specific size or colour in seconds, whether it’s hiding on a rail or buried in the stockroom.

This kind of quick, reliable service creates happy customers. They find what they want, they buy it, and they are much more likely to come back. It turns the classic, frustrating hunt for an item into a refreshingly simple and positive experience.

Are you ready to bring this level of precision and efficiency to your own production line? At Sessions UK, we provide a full range of labelling machinery to support businesses of all sizes. From manual labellers for artisan producers to fully automatic systems for high-volume operations, we have the right solution to match your needs. Discover our professional labelling machines and start your journey towards smarter production today.

Copyright © 2026 Sessions Label Solutions Ltd.