Label printing software is the command centre for your entire labelling operation. It is the brain that connects your design ideas, your product data, and your physical printer, bringing them all together into one cohesive system. For any UK business involved in logistics, retail, or manufacturing, getting this part right is necessary for accuracy and efficiency.

Think of label printing software as the digital bridge between your data and the physical label that ends up on your product. Before this kind of technology existed, creating labels was a manual job, full of disconnected steps and opportunities for mistakes. Now, it is a central part of supply chain management and brand identity, turning raw data into the scannable, informative labels that keep commerce moving.

At its most basic, label printing software gives businesses the tools to design, manage, and print labels for a large range of applications. This could be anything from simple address stickers to complex product labels packed with barcodes, batch codes, and regulatory data. A small artisan food producer might use it to create beautiful, branded jar labels, while a large warehouse will rely on it to produce thousands of shipping labels every single day.

To give you a clearer picture, let’s break down the main categories you’ll encounter.

This table outlines the main types of label printing software available, showing what they do best and who typically uses them.

| Software Type | Primary Function | Best For |

|---|---|---|

| Basic Design Software | Simple design and printing of text and graphics. | Small businesses, home offices, or anyone needing straightforward address or filing labels. |

| Barcode Software | Creating and managing various types of barcodes (1D and 2D). | Retail, inventory management, and logistics where scannable data is needed for tracking. |

| Enterprise-Level Systems | Full integration with business systems like ERP and WMS for automated, data-driven labelling. | Large manufacturers, distributors, and regulated industries needing high-volume, compliant labelling. |

| Cloud-Based Software | Web-accessible label design and management from anywhere. | Businesses with multiple locations, remote teams, or a need for flexible, collaborative access. |

Each type serves a different purpose, from simple one-off jobs to complex, automated workflows that are deeply embedded in a company’s operations.

The demand for good labelling software is growing fast. Here in the UK, the market is expanding, driven by the push for more automation and the need to meet strict regulatory standards. The global market, valued at around USD 2.07 billion, is on an upward trajectory, and the UK is following suit with a projected compound annual growth rate (CAGR) of about 12.28% between 2025 and 2032. This is not just a niche tool anymore; it is a core business system.

The software’s uses are varied and often tailored to very specific needs. For example, businesses can quickly and efficiently print badges for events, create detailed product information labels for retail shelves, or produce tough, durable asset tags for tracking equipment. For specialised tasks like bottling, having a system that works well is non-negotiable. You can learn more about this in our guide on the efficiency of a label printing machine for bottles.

One of the most powerful things this software does is translate complex data-like inventory numbers, batch codes, and expiry dates-into a simple, scannable format like a QR code or barcode. This single transformation is what underpins modern logistics and inventory management.

By centralising the whole process, this software solves a lot of common operational headaches. It slashes the risk of human error that comes from manual data entry and makes certain your branding looks consistent across every single label. It also gives you the agility to adapt to new rules or marketing campaigns without having to overhaul your entire production line.

When you start looking at software for labels printing, you’ll quickly notice a vast difference in quality. It’s not just about getting text onto a sticky bit of paper; some systems are basic tools, while others are powerful solutions built to help your business grow. Knowing what to look for is the first step to choosing wisely.

Think of it like choosing a vehicle. Any car can get you from A to B. But if your job is delivering goods, you need a van built with the right space, durability, and features for the task. It’s the same with professional label software – it’s kitted out with specific tools designed for business-level accuracy and efficiency.

At the core of any good labelling software is its design studio. Most basic programs let you add some text and maybe a simple image, but a professional system gives you much more control. We’re talking about creating intricate layouts, using custom fonts that match your branding perfectly, and embedding high-resolution graphics. To speed things up, many top-tier solutions also offer pre-designed templates.

One of the most critical design features is barcode generation. Good software won’t just create a generic barcode; it will support a whole range of them, including:

This isn’t just about aesthetics; it’s about function. A pharmaceutical company, for instance, relies on precise 2D codes for traceability, while a retail shop needs perfectly scannable EAN codes to keep the tills moving.

The best software acts like a flexible canvas, giving you the power to create labels that are not only compliant and functional but also a true extension of your brand identity. It should handle everything from simple address labels to complex, multi-layered chemical safety warnings.

Perhaps the biggest feature that separates the amateur from the professional software is data integration. This is the software’s ability to connect directly to your business data sources, whether that’s a simple spreadsheet, a complex database, or your company-wide Enterprise Resource Planning (ERP) system.

This connection allows you to automate the creation of hundreds, or even thousands, of unique labels without ever touching a keyboard. Imagine linking a label template to your product database; the software automatically pulls the product name, SKU, price, and barcode for every single item, printing them in sequence. This doesn’t just save time; it dramatically cuts down the risk of human error, which can be incredibly costly. It also supports better labelling and sustainability industry best practices for 2025 by minimising material waste from reprints.

Finally, even the best software is useless if it can’t talk to your hardware. Great label software must work harmoniously with a wide variety of printer brands and models. It needs to have native drivers that understand different printing technologies, including:

Proper compatibility makes certain that what you design on your screen is exactly what comes out of the printer-a principle known as WYSIWYG (What You See Is What You Get). Without this, you’re just setting yourself up for misaligned prints, unreadable barcodes, and a bin full of wasted labels.

Think of your software for labels printing and your printer as a team. The software is the architect drawing up the blueprints, and the hardware is the construction crew that brings those plans to life. If they don’t communicate perfectly, even the most brilliant design will end up as a useless, misprinted label. It’s a recipe for waste and a whole lot of frustration.

So, how do they talk to each other? The magic happens through a little bit of code called a printer driver.

The driver is a translator. Your design file is a complex document filled with specific fonts, colours, barcodes, and data. Your printer is a piece of machinery that only understands a very precise language of mechanical commands. The driver’s job is to translate your digital design into exact instructions the printer can follow, telling the print head where to move, how hot to get, and when to feed the next label. This is what makes certain the label you get in your hand looks exactly like the one you designed on your screen.

Good software goes beyond just hitting ‘print’. It needs to understand and control the specific technology inside your printer. In the world of commercial labelling, the two main players are thermal transfer and direct thermal printing, and your software must be smart enough to manage both.

Mastering these technologies is critical, especially in the growing UK label printers market. Valued at roughly USD 553.9 million in 2025, it’s expected to expand to USD 836.4 million by 2035. With thermal printing making up over 45% of this market, having software that can handle it expertly is non-negotiable. You can read more about the label printer market in the UK on futuremarketinsights.com.

The biggest takeaway here? Stop thinking of your label software and printer as two separate purchases. They are a single, integrated system. Mismatches between them are the number one cause of printing errors, wonky labels, and unreadable barcodes.

Getting this partnership right is the cornerstone of any efficient labelling operation. Of course, once the label is printed perfectly, the job isn’t done. The next stage is applying it to your product. To see how that works, have a look at our guide on how to use a label application machine for precise label placement to see the final piece of the puzzle.

When it comes to choosing software for printing labels, it’s easy to get sidetracked by long feature lists. The real goal isn’t to find the most powerful option on the market, but to find the one that fits your business like a glove.

Think about it: a small Etsy shop sending out ten or twenty parcels a day has completely different needs from a huge manufacturing plant that has to produce thousands of compliant labels for regulated goods. Taking the time to evaluate your needs properly from the start will save you from paying for features you’ll never touch-or even worse, finding your system can’t keep up just a year down the line.

The first, most critical question to ask is about your daily label volume. Are we talking a handful of shipping labels? Or a production line that spits out hundreds every hour? This one factor alone will point you toward the right class of software.

Then, you need to think about how complex your labels are. If you just need simple text and addresses, a basic design tool will probably do the job. But if you’re working with intricate barcodes, custom branding, and dynamic data pulled straight from a database, you’re going to need a much more sophisticated solution.

To make a smart decision, you need to break down your needs into a few key areas. Getting a clear picture of these points will guide you to the right software tier and save you a lot of headaches later on.

It is also worth thinking about how easily the software integrates with your existing data sources. For some, simplifying data handling with no-code tools is becoming a popular way to make these connections without needing a team of developers.

The software you choose today has to be able to support your business tomorrow. Take a moment to think about your company’s growth plans. A system that feels just right for now could quickly become a frustrating bottleneck in a couple of years.

Look for software that can grow with you. Many providers offer tiered plans or add-on modules, allowing you to scale up your capabilities as your needs become more complex.

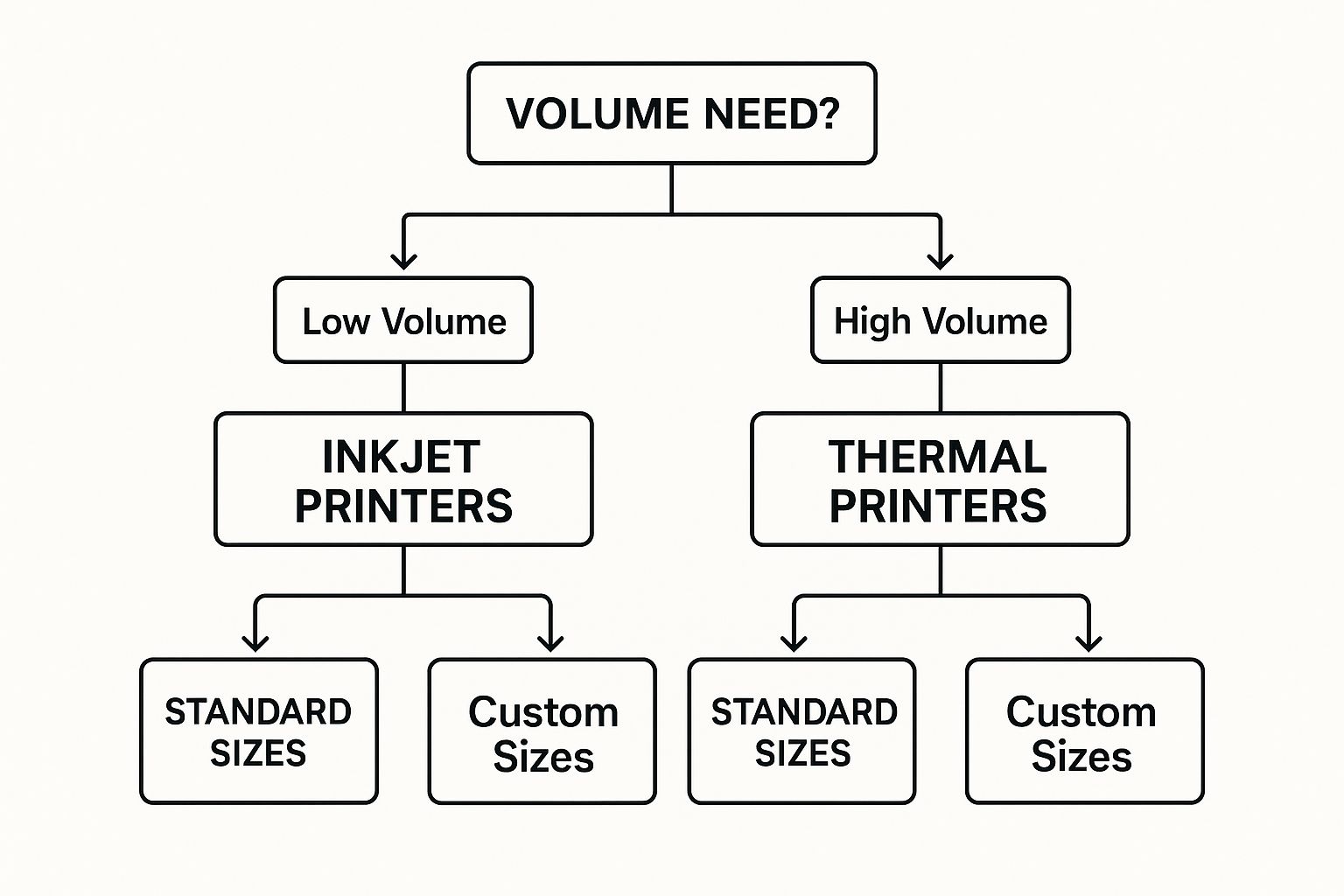

This is where your hardware comes into the picture, as your software and printer need to work in harmony. This infographic helps show how your volume and label size influence the type of printer you’ll need.

As you can see, high-volume needs almost always point towards thermal printers, which are brilliant for speed and efficiency, whether you’re printing standard or custom-sized labels.

Your software and hardware choices are two sides of the same coin. For more context on this, our guide on choosing the right labelling machine for your business is a great place to start.

Getting your new software for labels printing up and running smoothly is the secret to avoiding future headaches. When you take the time to set things up properly from the get-go, you’re building a reliable foundation for your entire labelling operation. It’s the best way to sidestep the common mistakes that eat into productivity and lead to a pile of wasted labels.

The first step is the software installation itself. Most modern programs come with helpful setup wizards, but it is still smart to follow the instructions to the letter. Once the software is on your computer, you need to introduce it to your physical label printer.

This connection hinges on installing the correct printer drivers. Think of a driver as a translator between your software’s design commands and the printer’s physical actions. A mismatch here is one of the most common reasons for printing errors. After the driver is in place, you’ll need to calibrate the printer, which is just a fancy way of saying you’re aligning the printhead with the label roll. This makes certain your designs come out sharp and perfectly centred every single time.

With the technical setup handled, the creative part begins: designing your first label templates. This is where you’ll lay out all the elements like text boxes, barcodes, and your company logo. The aim is to create a master template for each type of label you use regularly.

A powerful feature at this stage is linking your templates to a data source. Whether you’re working from a simple spreadsheet or a complex company database, connecting it to your label software is what unlocks real automation. This link pulls information like product names, SKUs, or shipping addresses directly onto the label, eliminating manual data entry and the inevitable typos that come with it.

Before you even think about printing a full batch, always run a few test prints. This simple step is your final quality check. Does the barcode scan properly? Is the text clear and easy to read? Are all the elements lined up correctly? Catching a problem now is far easier and cheaper than dealing with a rejected shipment later on.

Once your template is pulling the right data and the test prints look perfect, you’re ready to go.

Even the most sophisticated system is only as effective as the people using it. That’s why proper training is so important. You need to make certain every team member understands the new workflow from start to finish.

A good training session should walk them through the entire process:

By putting in the effort to set up the software, calibrate your hardware, and train your staff, you create a labelling process you can count on. This initial time investment pays dividends, giving you an efficient, error-free system that supports your business day in and day out.

When you start digging into the world of software for printing labels, a few questions always seem to surface. Getting good, straight answers is key to making a smart decision for your business without getting bogged down in jargon. Let’s tackle some of the most common ones.

One of the first things people worry about is compatibility. Will this new software actually work with the printers I already have? It’s a fair question. The good news is that most professional label software is built to play nicely with all the major printer brands, like Zebra, Brother, Honeywell, and Sato. They do this using dedicated printer drivers, which basically act as translators, making certain the design on your screen comes out exactly as intended on the physical label.

Another frequent query is about the real difference between free and paid software. Free tools can be fantastic for straightforward jobs-think simple address labels with a bit of text and maybe a logo. But when you need more power, paid software is where you’ll find it.

Upgrading to a paid version typically unlocks a whole new set of professional-grade tools:

For any business that’s growing, integration is a massive consideration. How exactly does label printing software talk to your other systems, like your warehouse management platform or an ERP such as Microsoft Dynamics 365?

This is where professional software really proves its worth. It’s designed from the ground up to connect with your central business data. Imagine a sales order comes through your ERP. The right software can automatically trigger the printing of the correct shipping label, pulling the address and tracking details without anyone lifting a finger. This is what turns labelling from a manual chore into a part of your operation, slashing errors and saving a huge amount of time.

The ability to integrate software with core business systems is what separates a simple design tool from a true operational asset. It makes certain data accuracy from the sales order all the way to the final package, creating a single source of truth.

This kind of automated workflow is a big change for efficiency. Instead of an employee manually typing or copying and pasting an address-and risking a mistake-the system does it all. This not only makes your order fulfilment faster but also guarantees the data on the label is 100% accurate because it’s pulled directly from the source.

Yes. Many modern software packages fully support on-demand colour printing. This is incredibly useful for making important information stand out, like allergen warnings on food packaging or safety symbols on chemical containers.

Colour can also be a powerful tool for your internal processes, helping to speed up warehouse sorting or just making your products pop on a crowded retail shelf. The software simply sends the design to a colour inkjet label printer, giving you high-quality labels whenever you need them. This flexibility means you no longer have to order and store huge quantities of pre-printed colour labels.

Ready to put all this into practice? Sessions UK provides a wide range of labelling machinery designed to work with professional software, helping your production line run smoothly and efficiently. Explore our labelling machines to find the right hardware for your setup.

Copyright © 2026 Sessions Label Solutions Ltd.