Tamper-evident labelling gives you a clear, undeniable sign that a product has been opened or messed with before it gets to the customer. It’s like the wax seal on an old letter-it won’t physically stop someone from breaking in, but it makes it obvious if they have. That visual proof is fundamental to product safety and building consumer trust.

At its core, a tamper-evident label is about communication. It sends a silent but powerful message to your customer: “This product is exactly as it was when it left our facility.” If that promise is broken, the label shows immediate, visible proof. This simple function is a safeguard for both brands and consumers, protecting them from serious risks like contamination, counterfeiting, and theft.

The urgent need for this kind of security became clear after major public safety scares. In the UK, high-profile incidents like the baby food contamination fears of the 1980s exposed how vulnerable unsecured products were. These events triggered huge product recalls, cost companies millions, and badly damaged public confidence. One of the key innovations to come from this period was the simple ‘safety button’ on vacuum-sealed jars-a brilliantly effective way to show a product’s integrity was intact.

When a customer sees an unbroken tamper-evident seal, it gives them instant confidence in what they’re about to buy or use. This is particularly true in industries where the purity and safety of the product are non-negotiable.

This visible commitment to safety demonstrates that a brand genuinely cares about its customers’ well-being, which is a fantastic way to build lasting loyalty. While these security labels are common in many sectors, the same principles of tracking and identification apply to other items, as you can see in our guide on material clothing labels.

A tamper-evident label’s primary job isn’t to be an unbreakable fortress. Its job is to be a reliable informant, telling the true story of the product’s journey from the production line to the shelf.

These labels serve a few key roles, all working together to protect the product and the consumer.

| Function | Description | Primary Benefit |

|---|---|---|

| Tamper Indication | Provides obvious, irreversible visual evidence if a seal is broken or removed. | Builds consumer trust and supports product integrity. |

| Deterrence | Discourages theft, product substitution, and unauthorised access during transit. | Reduces supply chain losses and protects brand reputation. |

| Authentication | Can incorporate features like holograms or QR codes to verify the product is genuine. | Fights counterfeiting and protects revenue. |

| Compliance | Helps meet regulatory requirements in industries like pharmaceuticals and food. | Avoids legal penalties and supports market access. |

These functions combine to create a security system that benefits everyone, from the manufacturer to the end-user.

Beyond keeping consumers safe, tamper-evident labelling is a powerful deterrent against theft and product swapping while goods are in transit. A properly sealed product is a less appealing target for anyone looking to steal contents or replace genuine items with fakes.

If tampering does happen, the broken seal acts as a clear red flag. It makes it much easier for your supply chain partners to identify where and when the breach occurred, helping you fix security weak spots in your logistics network. This kind of accountability is now a standard part of packaging strategy for any business operating in the UK or internationally.

When choosing the right tamper-evident label, you need to get familiar with the different technologies out there. Each type has its own clever way of showing clear, visual proof that someone has meddled with your product. The best fit depends on what you’re protecting, the type of packaging you use, and the specific risks you’re up against.

Think of it like picking a lock. You wouldn’t use a simple diary lock on a bank vault, would you? It’s the same principle here. A simple jar of jam needs a different kind of protection than a box of high-value electronics.

One of the most direct and effective methods is the destructible vinyl label. These are made from an incredibly brittle material paired with a very strong adhesive. Once you stick it on, it’s not coming off in one piece.

Try to peel one of these off, and it won’t lift cleanly. Instead, it shatters into dozens of tiny fragments, making it impossible to remove and reapply without leaving a complete mess. The evidence of tampering is immediate and undeniable.

For a more sophisticated approach, you have void labels. These are built with multiple layers that cleverly separate when peeled. As someone lifts the label, a hidden message-usually the word ‘VOID’ or a distinct checkerboard pattern-appears on the surface of the product.

At the same time, a corresponding pattern shows up on the back of the label itself, making it impossible to stick back down without the tampering being obvious. This two-part reveal is rock-solid proof.

Void labels are fantastic for protecting warranties. They make it crystal clear if a customer has opened up a device they shouldn’t have, which can void the warranty terms. This is a go-to solution for electronics and machinery.

These labels are also highly customisable. You can change the hidden message to your company name or a specific warning, adding an extra touch of security and brand reinforcement.

When you’re dealing with high-value goods and need to fight off counterfeiters, holographic seals are a top-tier choice. The sheer complexity of their multi-layered optical designs makes them incredibly difficult to replicate. Forging a custom hologram requires specialist equipment and deep expertise, which acts as a powerful deterrent.

Holographic labels can also pull double duty by incorporating other tamper-evident features. It’s common to see them combined with destructible materials or void technology, creating a seal that’s not only a nightmare to copy but also impossible to remove cleanly.

A completely different but very common method involves film wraps or shrink bands. You’ve definitely seen these before-think of the clear plastic seal over the cap of a new medicine bottle or a jar of sauce. These are plastic sleeves that are placed around the lid of a container and then shrunk tight using heat.

To get into the product, the customer has to physically tear or remove the band. Since there’s no way to put a broken band back together, it provides a simple, unmistakable sign that the product is factory-sealed and safe.

Comparing Key Label Types

| Label Type | Primary Mechanism | Example Application |

|---|---|---|

| Destructible Vinyl | Fragments into small pieces upon removal. | Asset tracking labels on company laptops. |

| Void Labels | Leaves a ‘VOID’ message on the surface. | Warranty seals on electronic devices. |

| Holographic Seals | Complex optical design is difficult to forge. | Authentication labels on software packaging. |

| Film Wraps | Must be physically broken to access the product. | Safety seals on over-the-counter medicine bottles. |

Each of these technologies offers a unique way to secure your products. Getting to grips with how they work is the first step in building a packaging strategy that truly protects your products, your brand, and your customers.

The power of a tamper-evident label isn’t just about sticking something on a package. The real magic is in the clever materials science and engineering happening behind the scenes. These labels are designed to fail in a very specific, very visible way, making it immediately obvious if someone has tried to gain access. Knowing how this works helps you see the difference between a simple seal and a genuine security feature.

At its core, every tamper-evident label is a combination of two things: the face material (what you see) and a special kind of adhesive. The security comes from how these two interact. They’re designed so that the bond to the product is stronger than the label itself, or they’re engineered to separate in a predetermined way, leaving behind undeniable proof of meddling.

One of the most common approaches uses frangible materials, like ultra-destructible vinyl or paper. These materials are deliberately manufactured to be brittle and have incredibly low internal strength. Think of it like a perfectly crisp cracker that shatters the moment you try to break it cleanly.

When someone tries to peel a label made from a frangible material, it doesn’t lift off in one piece. Instead, it fractures into countless tiny fragments. This crumbling action makes it physically impossible to remove and reapply the label. Any attempt leaves behind a torn, messy pattern that screams the seal has been broken. The adhesive is so aggressive that the label literally tears itself apart before it lets go of the surface.

The core principle of a destructible label is simple: its internal structure is weaker than its bond to the product. This makes certain that any attempt at removal results in self-destruction, providing clear evidence of tampering.

This method is incredibly effective for things like warranty seals on electronics or asset tags, where the main goal is simply to prove an item hasn’t been opened or moved.

Void labels work in a completely different way, using a sophisticated multi-layered construction. They aren’t made from a single material but from several layers that are engineered to separate when put under stress. This sandwich typically includes a top film, a release layer, and an adhesive layer.

When the label is peeled back, these layers split apart. The top film lifts away, but a hidden pattern and part of the adhesive are left behind permanently on the product’s surface. This process reveals a pre-printed message-most often the word ‘VOID’, though it can be customised with other text or patterns. This two-part separation makes it impossible to reapply the label without the tampering being glaringly obvious.

Beyond these fundamental mechanics, tamper-evident labels can be beefed up with advanced features for even tighter protection. Adding these extra layers makes counterfeiting and tampering significantly more difficult.

When you combine these technologies, a simple sticker becomes a sophisticated security device. The smart engineering behind tamper-evident labelling is what provides real peace of mind, demonstrating a clear commitment to product integrity and consumer safety.

When it comes to tamper-evident labelling, we’re not just talking about good practice or building customer trust. In many industries, it’s a firm legal requirement. For anyone operating in the UK, especially in pharmaceuticals and food where public safety is non-negotiable, getting to grips with these rules is critical. Get it wrong, and you could be looking at hefty penalties, product recalls, and losing your access to the market entirely.

These regulations aren’t just red tape. They exist for a very good reason: to build a secure supply chain that protects people from the real dangers of counterfeit or contaminated products. As a production manager, the first step is always to understand these obligations. It’s the only way to be certain your products are both safe and legally ready for sale in the UK.

The pharmaceutical sector operates under some of the tightest packaging rules you’ll find. A defining piece of legislation for tamper-evident labelling in the UK was the EU Falsified Medicines Directive (2011/62/EU). Since 9 February 2019, this directive has mandated that prescription medicines carry two crucial safety features: a unique identifier and an anti-tampering device.

Even with the UK’s departure from the EU, these protective principles are still a core part of UK medicine safety, enforced by the Medicines and Healthcare products Regulatory Agency (MHRA).

For medicines, this means the outer packaging must have a feature-like a securely glued carton flap or a perforated seal-that clearly shows if it has been opened. It’s a simple, at-a-glance check for pharmacists and patients.

This visible evidence is the first line of defence. It works hand-in-glove with the unique identifier, usually a 2D barcode, which allows every single pack to be scanned and verified before it’s dispensed. This creates a powerful, closed-loop system that makes it incredibly difficult for fake medicines to slip through.

The food and drink industry has its own compliance challenges. While the rules might not be as universally mandated as in pharmaceuticals, tamper-evident features are still a must-have for many products under general food safety legislation. The Food Safety Act 1990 makes it a clear offence to sell food that isn’t of the nature, substance, or quality the customer expects.

What does that mean in practice? If your product is vulnerable to tampering or contamination, you have a duty to protect it. A broken seal on a jar of baby food or a cracked lid on a pot of yoghurt could make the product unsafe, leaving the manufacturer liable.

Familiar examples you’ll see on shelves every day include:

For any business wanting to stay on top of the latest rules, keeping your knowledge current is a good idea. You can get a deeper insight by reading our guide on understanding label regulations in our 2025 guide for production teams.

Achieving compliance isn’t as simple as just slapping on a seal. The solution you choose must be genuinely fit for purpose and properly integrated into your production line.

To be considered compliant, a tamper-evident device must:

This brings us to a critical point for manufacturers: your choice of labelling machinery is just as important as your choice of label. Your equipment has to apply these security features reliably and consistently, time after time, so that every single product that leaves your factory is fully compliant.

Picking the right tamper-evident solution isn’t about finding a single “best” option. It’s about finding the one that perfectly fits your product, your risks, and your budget. After all, a high-tech holographic label on a sandwich is complete overkill, but a simple paper seal on a high-value electronic device just won’t cut it.

The best way forward is to ask a few smart questions. By thinking through your specific situation first, you can have a much more meaningful conversation with a label supplier and make sure you’re investing in security that actually makes sense for your business.

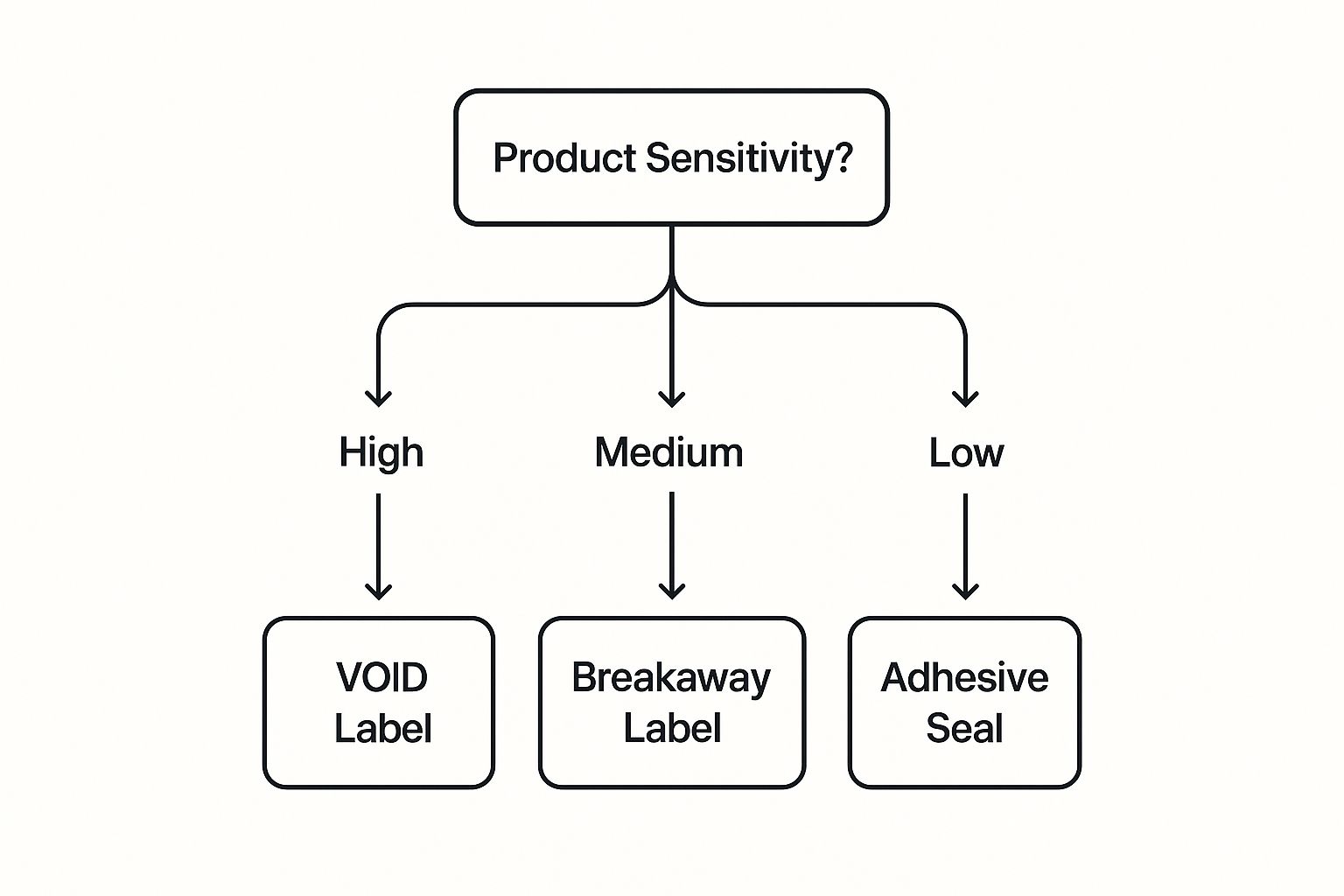

This decision tree shows how the sensitivity of your product can point you towards the right kind of tamper-evident technology.

As you can see, there’s a clear logic here. High-risk items get the most benefit from advanced solutions like VOID labels, whereas everyday goods can be secured perfectly well with simpler, frangible seals.

Let’s break it down. Working through these practical questions will help you zero in on the ideal tamper-evident labelling strategy for your product line.

1. What’s the value and sensitivity of your product?

This is always the starting point. Are you protecting a high-value piece of tech where warranty fraud is a real headache, or a food item where the main concern is contamination? The higher the stakes-whether financial or safety-related-the more solid your solution needs to be.

2. What kind of surface are you labelling?

An adhesive that sticks like a dream to a smooth glass jar might peel right off a porous, recycled cardboard box. You have to match the label to the packaging material.

3. What environmental conditions will it face?

Think about the entire journey your product takes, from your factory floor to your customer’s hands. Will it be sitting in a freezer, rattling around in a humid lorry, or basking in direct sunlight on a shop shelf? Extreme temperatures and moisture can wreak havoc on an adhesive’s performance.

Once you’ve got the practicalities sorted, it’s time to think about what you want the label to do and say.

4. What should the label communicate if tampered with?

Do you need an unmistakable message, like a bold ‘VOID’ pattern appearing? This is brilliant for managing warranty claims. Or is a simple, fragmented seal that just shows the package has been opened enough? Your answer here will guide you directly towards either a void label or a destructible one.

The message of a tamper-evident label is its core function. Whether it whispers “opened” through subtle fragmentation or shouts “VOID” with a bold reveal depends entirely on the level of risk and the action you want to trigger.

5. What’s your budget per unit?

Security has a price tag, and it has to be proportionate to the product’s value. A basic paper seal might cost a fraction of a penny. A custom holographic void label could be considerably more. You need to calculate your acceptable cost-per-item to immediately filter out options that simply aren’t financially practical. This principle applies to other identification needs, too; for a different angle, you can look into label printing for clothing.

Sometimes, a truly comprehensive security plan goes beyond just the label. For high-value goods in transit, a layered approach is often the best bet. Exploring innovative container lock solutions can add another, much-needed physical barrier.

By answering these questions, you’ll have a clear and detailed brief to take to a labelling specialist. This process will help you find a solution that protects your product, your brand, and your bottom line.

Whenever you’re bringing a new process into your operations, it’s only natural to have questions. To help you feel confident about adding tamper-evident labels, we’ve put together answers to some of the queries we hear most often. This should clear up the practical side of boosting your product security.

This is a really common point of confusion, but the distinction is critical. The two terms sound similar, but they describe entirely different security functions and you shouldn’t use them interchangeably.

A tamper-evident feature is all about showing proof. Its job is to provide clear, irreversible visual evidence that a product has been opened or messed with. It’s not designed to stop a determined person, but to make certain any attempt is immediately obvious. A classic example is a label that leaves a “VOID” message behind when peeled off; the evidence is the whole point.

A tamper-resistant feature, on the other hand, is designed to make unauthorised access physically harder. It’s a barrier that requires more time, effort, or even special tools to get past. Think of a child-resistant cap on a medicine bottle-you need that specific “push-and-twist” action to open it.

While many great packaging solutions use both, the main goal of tamper-evident labelling is communication. It tells a story of integrity or interference.

Yes, absolutely. In fact, customisation is one of the most powerful things about modern tamper-evident labelling. You can certainly buy basic, off-the-shelf labels, but creating a custom one gives you a huge advantage in both security and branding.

You can customise your labels in a few key ways:

Customising your labels doesn’t just make them tougher for counterfeiters to copy; it also reinforces your brand identity. The first step is figuring out exactly what you need, and you can learn more by checking out our guide on how to create effective labels.

A custom tamper-evident label does more than just secure a product; it becomes a part of your brand’s voice, communicating a commitment to quality and safety directly to the consumer.

Proper application is every bit as important as the label itself. A badly applied label can easily fail, giving you a false sense of security.

To get the most out of your labels, stick to these key steps:

For any kind of high-volume production, using a proper labelling machine is the only way to guarantee every label is applied consistently and correctly, every time.

No, there isn’t a blanket rule that every single product must have one. The regulations are very strict in certain sectors where consumer safety is the top priority.

In the UK, tamper-evident features on medicine packaging are a critical and heavily regulated part of the pharmaceutical supply chain, mainly to stop fake products. The UK’s Medicines and Healthcare products Regulatory Agency (MHRA) mandates these features to give a clear, visible sign of any tampering. Before these rules were tightened, it was estimated that counterfeit medicines could make up as much as 4% of the UK market. Today, these measures are used on almost all prescription and over-the-counter medicines. You can explore the full scope of these rules in this guide on medicine packaging regulations on globalvision.co.

When it comes to food and drink, it’s less about a single law and more about the general duty of care under the Food Safety Act. If a product could be tampered with in a way that makes it unsafe, the manufacturer is expected to use appropriate protective packaging.

At Sessions UK, we understand that choosing the right security solution is a critical decision. Our expert team is here to help you navigate the options, from selecting the perfect tamper-evident material to implementing the ideal labelling machinery for your production line. We provide reliable equipment that helps you maintain compliance and protect your brand.

Discover our full range of professional labelling solutions at https://sessionsuk.com.

Copyright © 2026 Sessions Label Solutions Ltd.